Stirring shaft of banburymixer

A mixer and agitating shaft technology, applied in mixers, mixers with rotary stirring devices, dissolving and other directions, can solve the problems of low production efficiency, long time required, long mixing time, etc., and achieve high uniformity, The effect of facilitating heat dissipation and shortening the mixing cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

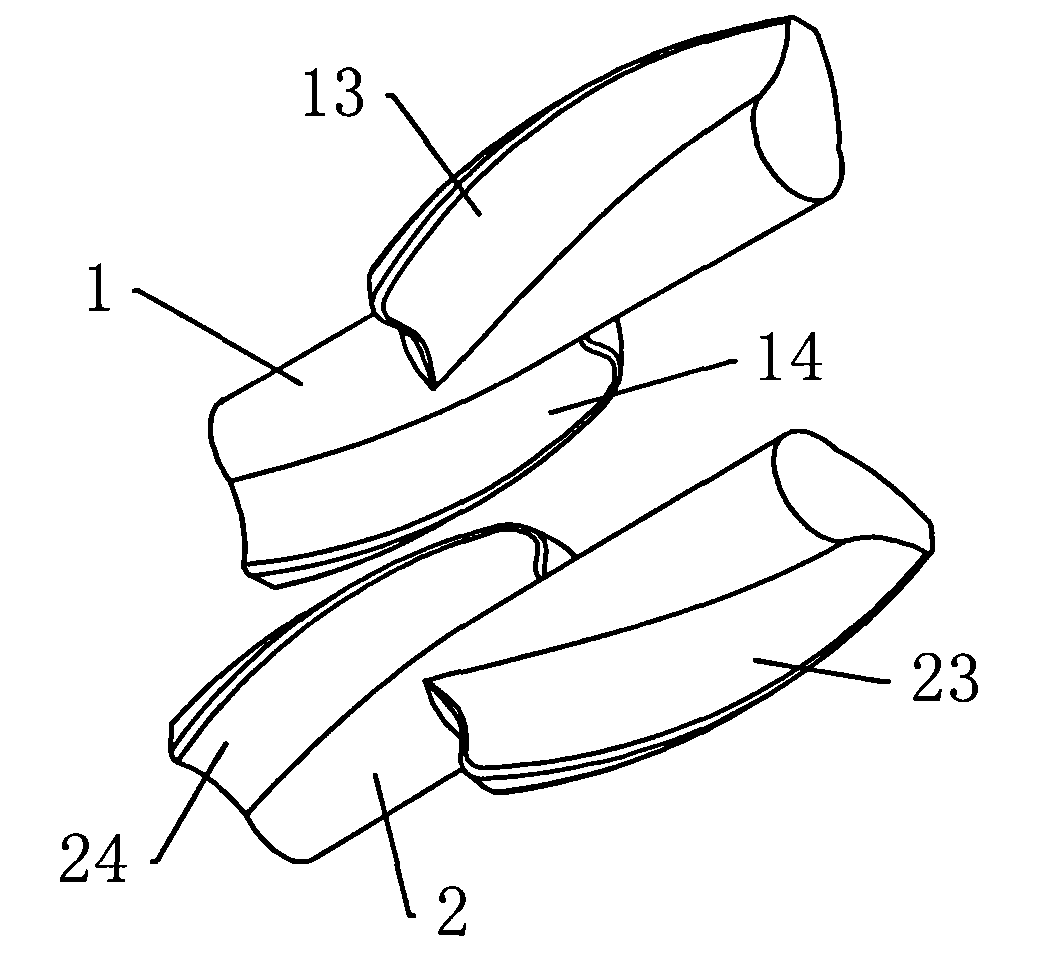

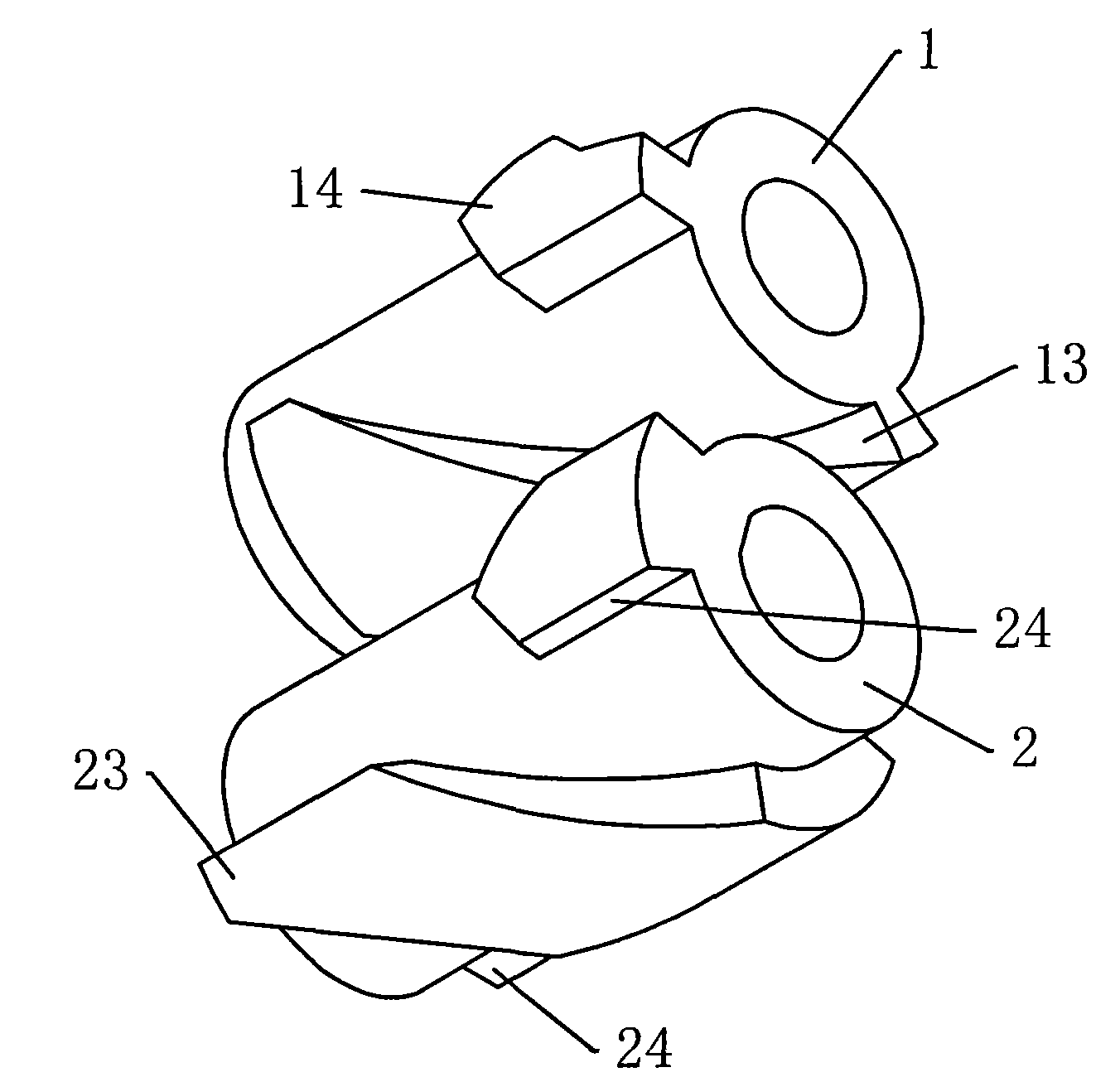

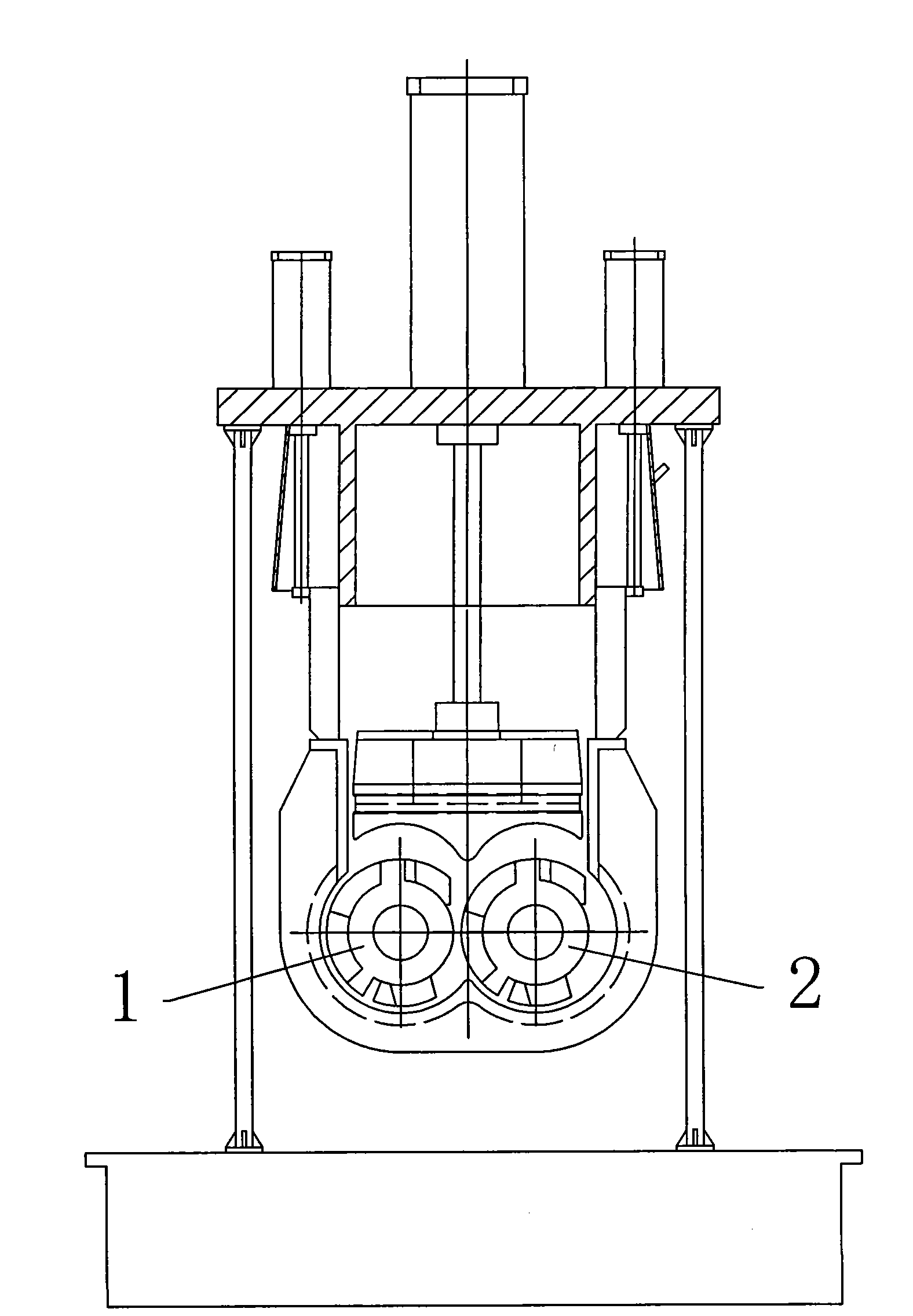

[0016] As shown in the figure, the mixing shaft of the internal mixer includes two parallel first rotors 1 and second rotors 2 that rotate relatively under the drive of the power mechanism. There are spiral ribs 13 on the cylindrical surface of the first rotor. A boss 14 is respectively set on the cylindrical surface at both ends of the first rotor; a helical rib 23 is arranged on the cylindrical surface of the first rotor, and a boss 24 is respectively arranged on the cylindrical surface at the two ends of the second rotor. When the first rotor 1 and the second rotor 2 rotate relative to each other, the protrusion 14 and the helical rib 13 on the first rotor extend into the gap between the helical rib 23 and the protrusion 24 on the second rotor successively; The protrusion 24 and the helical rib 23 on the second rotor successively extend into the gap between the helical rib 13 and the protrusion 14 on the first rotor. The surfaces of the first rotor and the second rotor are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com