Graphene lubricating oil additive and preparation method thereof

A lubricating oil additive, graphene technology, applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve problems such as corrosion, achieve the effect of reducing noise, reducing harmful gases, and improving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

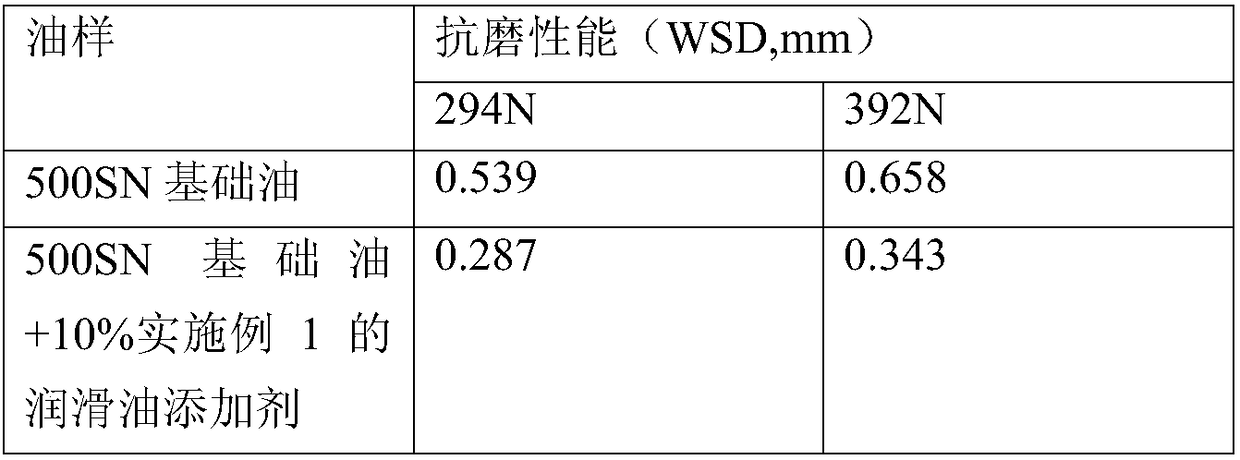

Embodiment 1

[0012] A graphene lubricating oil additive, the components and mass fractions are as follows: 5 parts of graphene oxide suspension, 5 parts of nano calcium carbonate, 4 parts of nano boron nitride, 3 parts of nano molybdenum disulfide, 8 parts of expanded graphite, nano 5 parts of zirconia, 2 parts of nano-alumina, 1 part of nano-titanium dioxide, 1 part of nano-silica, 5 parts of N,N'-di-sec-butyl-p-phenylenediamine, 4 parts of di-tert-butyl-p-cresol , 5 parts of polyvinyl alcohol, 2 parts of methyl acrylate, 5 parts of pentaerythritol, and 8 parts of nano zinc oxide.

[0013] The preparation process of the graphene oxide suspension is as follows: add 1 part of flake graphite powder and 0.5 part of sodium nitrate to 10 parts of concentrated sulfuric acid, slowly add 3 parts of potassium permanganate after 1 hour, control the temperature at 4 ° C, and react for 2 hours. Then react at 30°C for 1 hour, add 60 parts of water to the mixture, react at 70°C for 1 hour, then add 40 p...

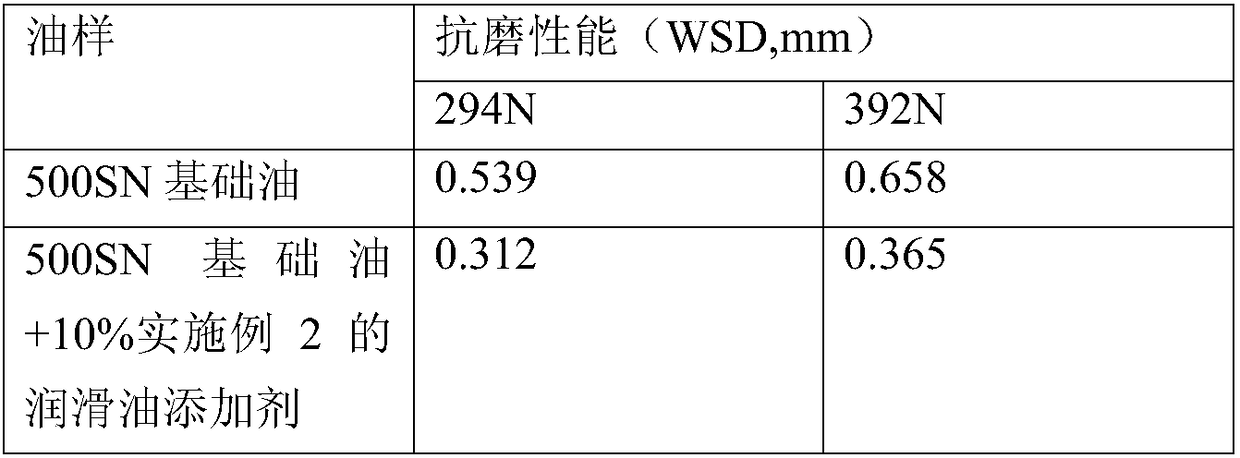

Embodiment 2

[0017] A graphene lubricating oil additive, the components and mass fractions are as follows: 20 parts of graphene oxide suspension, 1 part of nano calcium carbonate, 2 parts of nano boron nitride, 6 parts of nano molybdenum disulfide, 2 parts of expanded graphite, nano 1 part of zirconia, 8 parts of nano-alumina, 6 parts of nano-titanium dioxide, 8 parts of nano-silica, 3 parts of N,N'-di-sec-butyl-p-phenylenediamine, 6 parts of di-tert-butyl-p-cresol , 2 parts of polyvinyl alcohol, 8 parts of methyl acrylate, 1 part of pentaerythritol, and 2 parts of nano zinc oxide.

[0018] The preparation process of the graphene oxide suspension is as follows: add 1 part of flake graphite powder and 0.5 part of sodium nitrate to 15 parts of concentrated sulfuric acid, slowly add 3 parts of potassium permanganate after 1 hour, control the temperature at 10 ° C, and react for 2 hours. Then react at 35°C for 1 hour, add 80 parts of water to the mixture, react at 90°C for 1 hour, then add 50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com