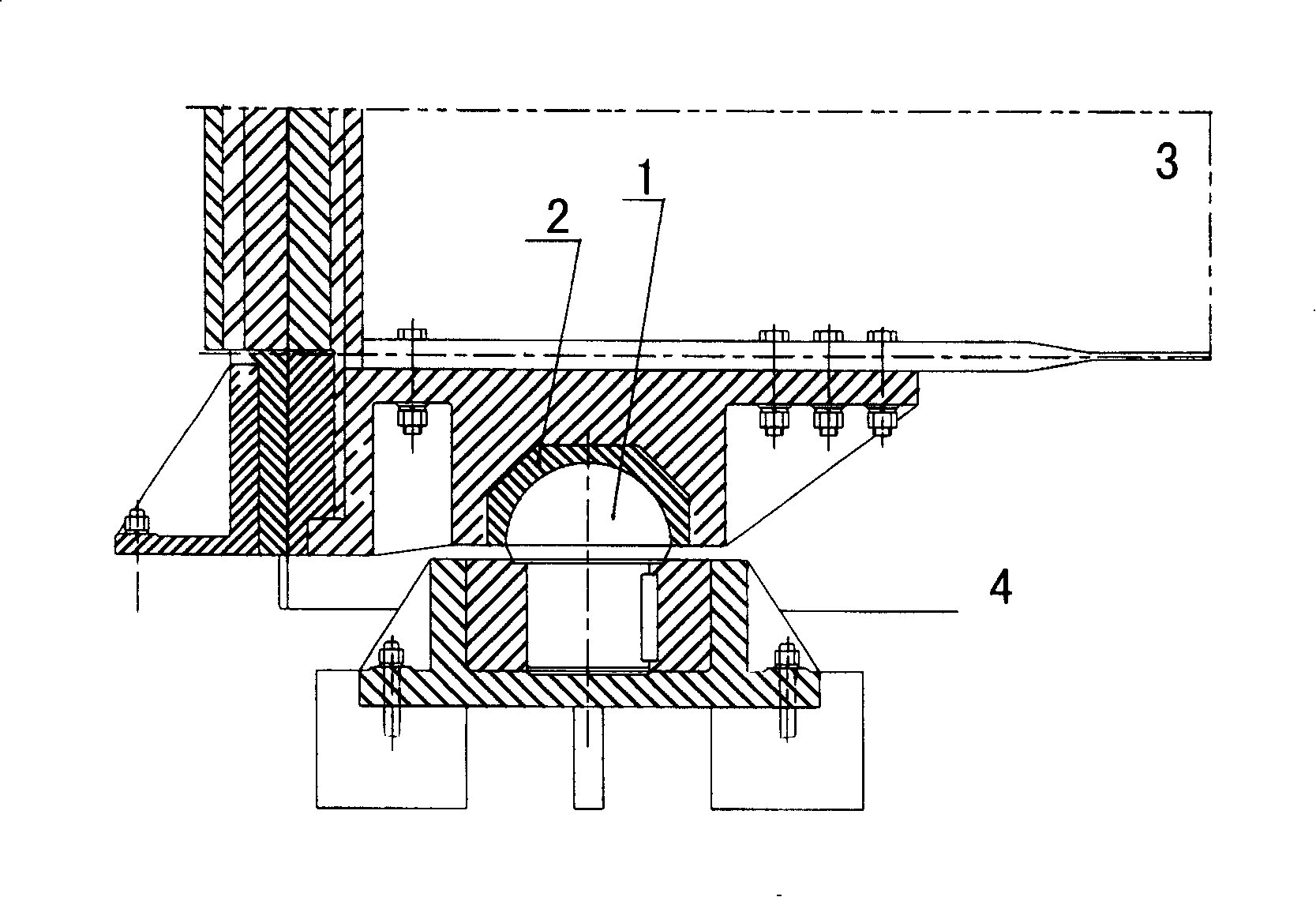

Ship lock mushroom head, mushroom head cap and processing method thereof

The technology of mushroom head cap and mushroom head is applied in the field of metal materials, which can solve the problem of wear and tear of mushroom head cap, and achieve the effects of improving wear resistance, significant economic and social benefits, and prolonging the period of major repairs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

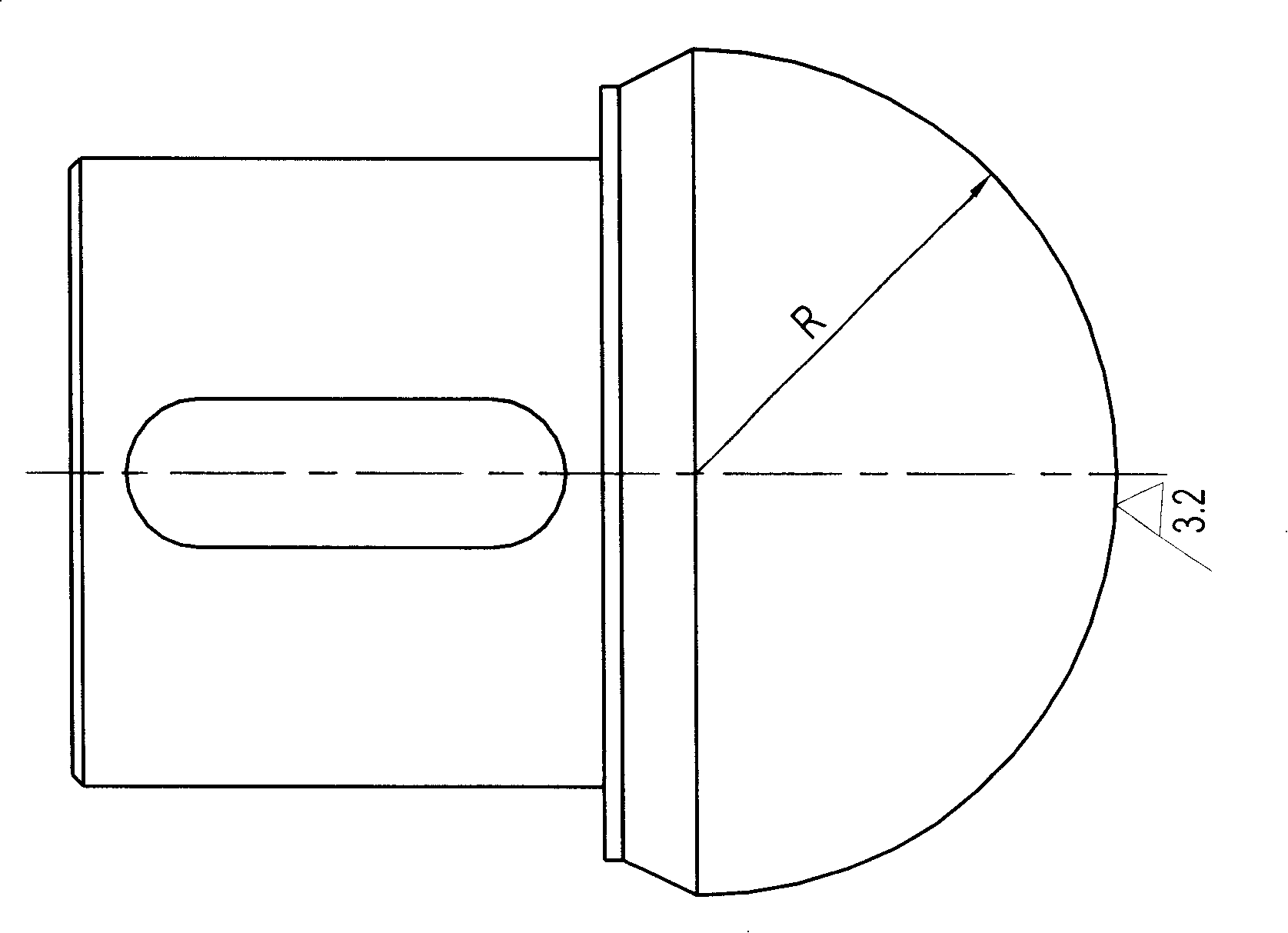

[0014] Example 1: The mushroom head adopts forged 40Cr ball surface quenching HRc45, and the mushroom head cap adopts 38CrMoAlA spherical nitriding HV900.

[0015] The chemical composition of the 40Cr material used is: C content 0.37-0.44%, Si content 0.17-0.37%, Mn content 0.50-0.80%; Cr content 0.80-1.10%.

[0016] The chemical composition of the 38CrMoAlA material used is: C content 0.35-0.42%, Si content 0.20-0.45%, Mn content 0.30-0.60%; Cr content 1.35-1.65%, Mo content 0.15-0.25%; Al content 0.70-1.10%.

[0017] Mushroom head adopts forging 40Cr process requirements: forging→stress relief annealing→lathe machining allowance→quenching and tempering treatment HB240→NC lathe finishing turning→ball surface quenching HRc45: induction heating to 860℃~880℃ Minutes, immediately put in oil or water to cool quickly after coming out of the oven. → Polishing.

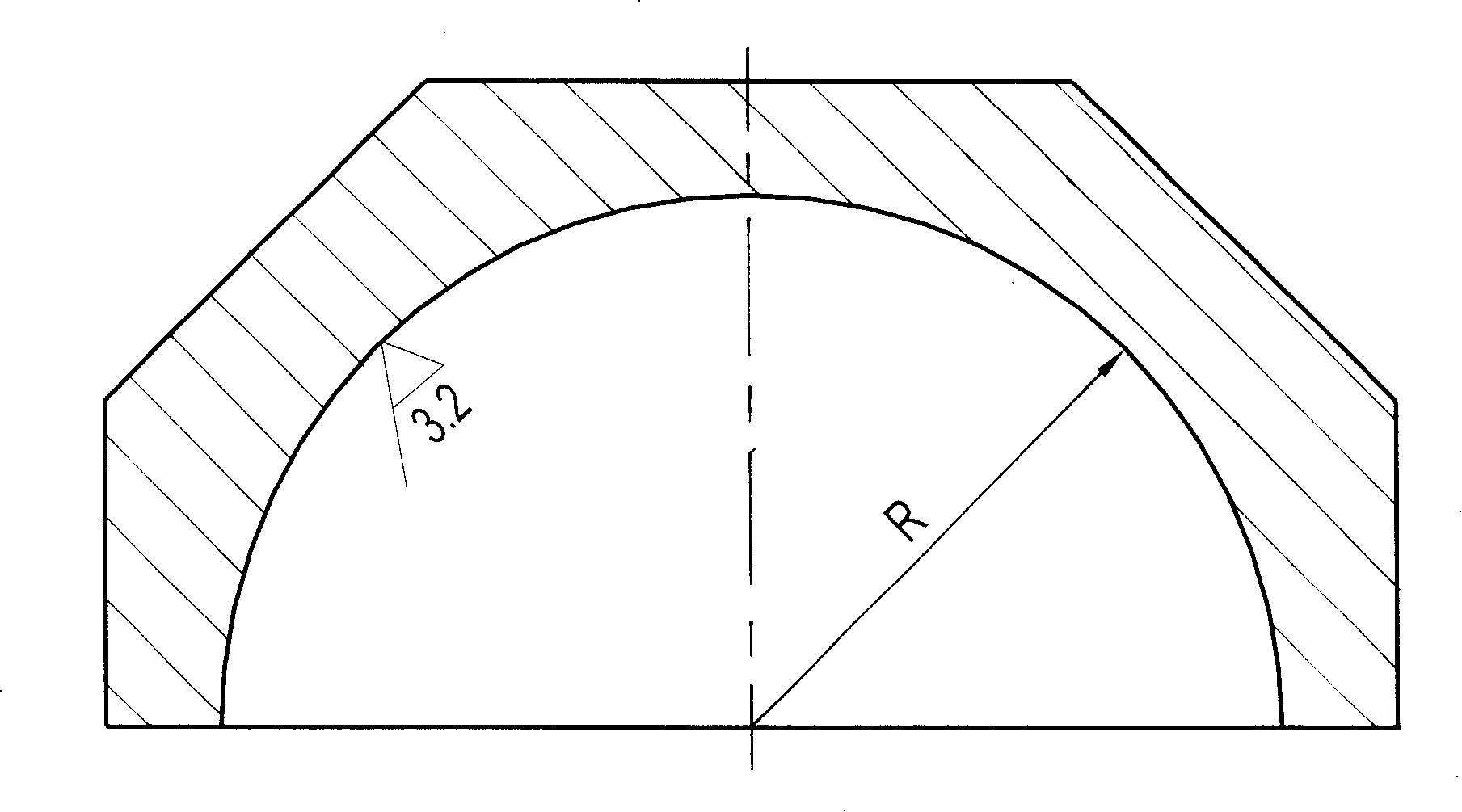

[0018] Mushroom head cap adopts 38CrMoAlA process requirements: forging → stress relief annealing → lathe rough processi...

Embodiment 2

[0019] Example 2: The mushroom head adopts 4Cr13 spherical surface quenching HRc45, and the mushroom head cap adopts 38CrMoAlA spherical nitriding HV900.

[0020] The chemical composition of the 38CrMoAlA material used is: C content 0.35-0.42%, Si content 0.20-0.45%, Mn content 0.30-0.60%; Cr content 1.35-1.65%, Mo content 0.15-0.25%; Al content 0.70-1.10%.

[0021] The chemical composition of the 4Cr13 material used is: C content 0.36-0.45%, Si content ≤ 0.60%, Mn content ≤ 0.80%; P content ≤ 0.035%, S content ≤ 0.030%; Cr content 12.0-14.0%.

[0022] Mushroom head adopts 4Cr13 process requirements: forging → stress relief annealing → lathe machining allowance → quenching and tempering HB240 → CNC lathe finishing turning → ball surface quenching HRc45 → polishing.

[0023] Mushroom head cap adopts 38CrMoAlA process requirements: forging → stress relief annealing → lathe rough processing → quenching and tempering treatment HB240 → lathe finishing → polishing → ball surface nit...

Embodiment 3

[0024] Example 3: The mushroom head adopts forged 40Cr ball surface quenching HRc45, and the mushroom head cap adopts QT600-3 spherical nitriding HV600.

[0025] The chemical composition of the 40Cr material used is: C content 0.37-0.44%, Si content 0.17-0.37%, Mn content 0.50-0.80%; Cr content 0.80-1.10%.

[0026] The chemical composition of the QT600-3 material used is: C content 3.56-3.85%, Si content 1.83-2.56%, Mn content 0.49-0.70%; S content 0.016-0.045%, P content 0.035-0.058%; RxOy content 0.033-0.049 %; Mg content 0.041 ~ 0.067%.

[0027] Mushroom head adopts forging 40Cr process requirements: forging→stress relief annealing→lathe machining allowance→quenching and tempering HB240→NC lathe finishing turning→ball surface quenching HRc45→polishing.

[0028] The mushroom head cap adopts QT600-3 process requirements: casting → normalizing HB220 → lathe rough machining → quenching and tempering treatment HB240 → lathe finishing → ball surface nitriding treatment Heat for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com