Ceramic anodizing solution and ceramic anodizing process

A technology of anodizing and ceramics, applied in the direction of anodizing, etc., can solve the problems that there is no ceramic anodizing solution and ceramic anodizing process, and the hardness is not as good as that of ceramic anodizing, so as to expand the range of surface decoration color, maintain the surface enamel feeling, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Ceramic anodizing solution, including each component of following mass concentration:

[0022] Chromium trioxide 30g / L;

[0023] Oxalic acid 1g / L;

[0024] Boric acid 1g / L.

Embodiment 2

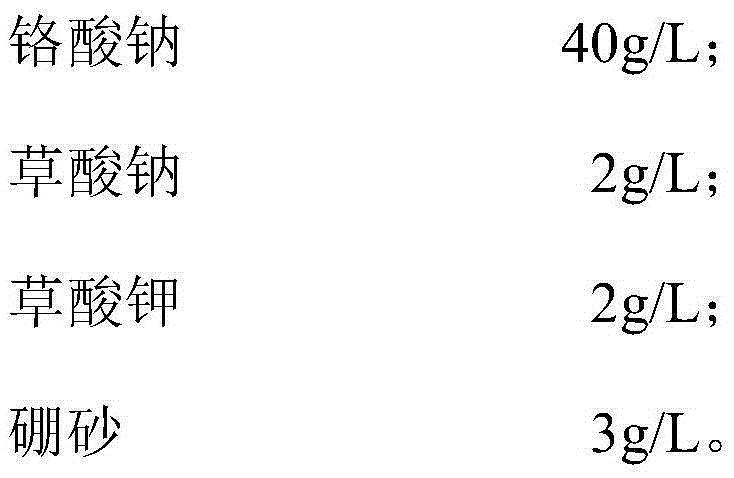

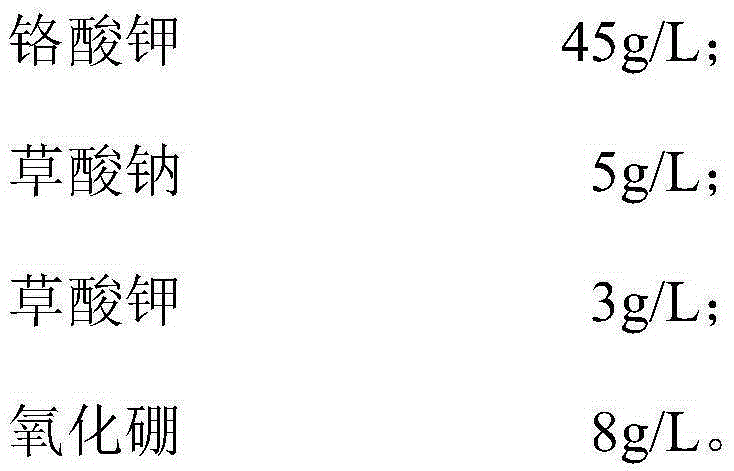

[0026] Ceramic anodizing solution, including each component of following mass concentration:

[0027] Chromic acid 80g / L;

[0028] Sodium oxalate 30g / L;

[0029] Borax 30g / L.

Embodiment 3

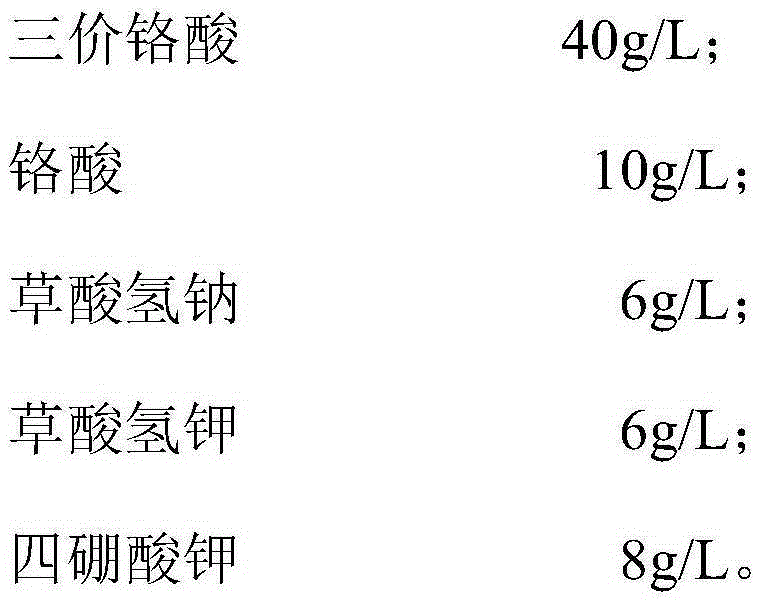

[0031] Ceramic anodizing solution, including each component of following mass concentration:

[0032] Pizza grass 35g / L;

[0034] Sodium metaborate 3g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com