Pole lug nickel strap surface treatment passivation solution

A technology of surface treatment and passivation solution, which is applied in the direction of metal material coating process, etc., can solve the problem of poor adhesion between passivation film and tab glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0046] As an embodiment, the inorganic acid is one or more of sulfuric acid, hydrochloric acid, phosphoric acid, perchloric acid, lactic acid, hydrofluoric acid, and acetic acid.

[0047] As an embodiment, the film-forming accelerator is one or more of ammonium vanadate, strontium chloride, hydrofluoric acid, malonic acid, oxalic acid, glutaric acid, malic acid, and maleic acid.

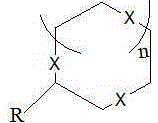

[0048] As an embodiment, the passivation solution for the surface treatment of tab nickel strips also includes 0.01-1 parts by weight of a compound of a cyclic polyether compound and modified graphene, and the cyclic polyether compound The structural formula is:

[0049]

[0050] Wherein, R is amino, carboxyl, hydroxymethyl, phenyl, acyl or alkoxy;

[0051] X is one or more of O, S and N;

[0052] n=1-10.

[0053] As an embodiment, the modified graphene is hydroxylated graphene, carboxylated graphene, sulfonated graphene or aminated graphene.

[0054] As a preferred manner, the modified graphe...

Embodiment

[0142] The present invention is specifically described below by way of examples. It is necessary to point out that the following examples are only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention, some non-essential improvements made by those skilled in the art according to the content of the present invention above And adjustments still belong to the protection scope of the present invention.

[0143] In addition, unless otherwise stated, the raw materials used are all commercially available, and the parts used in the following materials are all parts by weight.

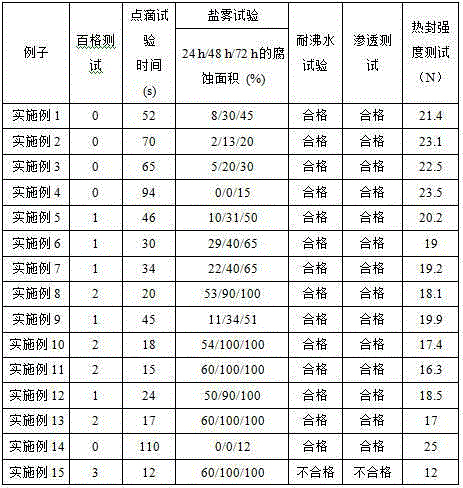

[0144] Table 1

[0145]

[0147] C: Inorganic acid

[0148] D: film-forming accelerator

[0149] E: Phytic acid

[0150] H: water

[0151] I: Others: cetyltrimethylammonium bromide, benzotriazole, organic phosphonic acid

[0152] Table 2 is the raw material formulation and dosage (parts by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com