Ventilated brick and preparation method thereof

A technology of breathable bricks and particle size range, applied in the field of refractory materials, can solve the problems of high sintering temperature, no resistance to slag penetration, and short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

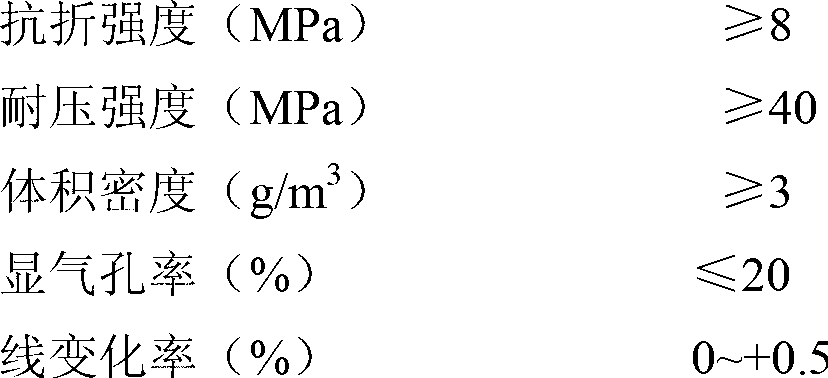

Examples

Embodiment 1

[0099] A kind of breathable brick, the weight part of raw material is composed of:

[0100] ①Dense fused corundum: particle size range 8~5mm 14 parts

[0101] ②Sintered tabular alumina: particle size range 6~3mm 28 parts

[0102] Particle size range 3 ~ 1mm 15 parts

[0103] Particle size range 1~0mm 15 parts

[0104] 100 mesh 6 parts

[0105] ③Sintered spinel: 2 parts of 100 mesh

[0106] ④ Fused magnesia: 0.5 part of 200 mesh

[0107] ⑤ Activated alumina micropowder: particle size ≤ 4.5μm 3 parts

[0108] ⑥Industrial chromium oxide: particle size ≤5μm 2 parts

[0109] ⑦Alumina-rich spinel powder: particle size ≤4.5μm 9 parts

[0110] ⑧Pure calcium aluminate cement: 2 parts

[0111] ⑨SM water reducer: 0.16 parts

[0112] SN-2 superplasticizer: 0.03 parts

[0113] ⑩Spray aluminum powder: 0.025 parts of 60-150 mesh

[0114] Polypropylene fiber: 0.06 copies;

[0115] The preparation steps are as foll...

Embodiment 2

[0125] A kind of breathable brick, the weight part of raw material is composed of:

[0126] ①Dense fused corundum: particle size range 8~5mm 18 parts

[0127] ②Sintered tabular alumina: particle size range 6~3mm 32 parts

[0128] Particle size range 3~1mm 21 parts

[0129] Particle size range 1~0mm 21 parts

[0130] 100 mesh 10 parts

[0131] ③Sintered spinel: 6 parts of 100 mesh

[0132] ④ Fused magnesia: 2 parts of 200 mesh

[0133] ⑤Activated alumina micropowder: particle size ≤4.5μm 6 parts

[0134] ⑥Industrial chromium trioxide: particle size ≤5μm 4 parts

[0135] ⑦Alumina-rich spinel powder: particle size ≤4.5μm 15 parts

[0136] ⑧Pure calcium aluminate cement: 4 parts

[0137] ⑨SM water reducer: 0.25 parts

[0138] SN-2 superplasticizer: 0.06 parts

[0139] ⑩Spray aluminum powder: 0.025 parts of 60-150 mesh

[0140] Polypropylene fiber: 0.07 copies;

[0141] The preparation steps are the sam...

Embodiment 3

[0143] A kind of breathable brick, the weight part of raw material is composed of:

[0144] ①Dense fused corundum: particle size range 8~5mm 15 parts

[0145] ②Sintered tabular alumina: particle size range 6~3mm 28 parts

[0146] Particle size range 3~1mm 16 parts

[0147] Particle size range 1~0mm 16 parts

[0148] 100 mesh 7 parts

[0149] ③Sintered spinel: 4 parts of 100 mesh

[0150] ④ Fused magnesia: 200 mesh 1 part

[0151] ⑤Activated alumina micropowder: particle size ≤4.5μm 4 parts

[0152] ⑥Industrial chromium oxide: particle size ≤5μm 2 parts

[0153] ⑦Alumina-rich spinel powder: particle size ≤4.5μm 11 parts

[0154] ⑧Pure calcium aluminate cement: 2 parts

[0155] ⑨SM water reducer: 0.16 parts

[0156] SN-2 superplasticizer: 0.03 parts

[0157] ⑩Spray aluminum powder: 0.025 parts of 60-150 mesh

[0158] Polypropylene fiber: 0.07 copies;

[0159] The preparation steps are the same as in E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com