Preparation method of high conductivity graphene

A graphene and graphite technology, applied in the field of graphene, can solve problems such as high cost, high equipment requirements, dangerous reaction, etc., and achieve the effects of avoiding pollution, reducing production cost and increasing dispersion speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a kind of preparation method of graphene, is characterized in that, comprises the following steps:

[0041] A) graphite, chromium trioxide and concentrated hydrochloric acid are reacted to obtain an intercalated graphite compound;

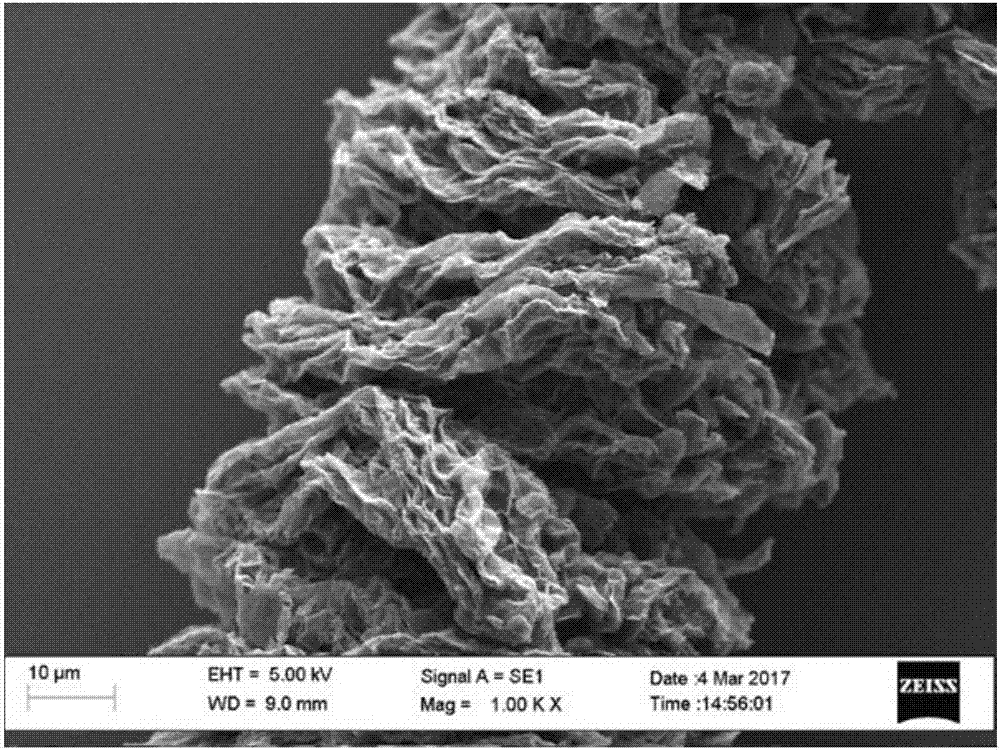

[0042] B) after mixing the intercalated graphite compound obtained by the above steps with hydrogen peroxide, obtain expanded graphite;

[0043] C) exfoliating the expanded graphite obtained in the above steps in the water phase to obtain graphene.

[0044] In the invention, graphite, chromium trioxide and concentrated hydrochloric acid are firstly reacted to obtain intercalation graphite compound.

[0045] The present invention has no special restrictions on the selection of the graphite, and the graphite materials well known to those skilled in the art can be used. Those skilled in the art can select and adjust according to actual production conditions, product requirements and quality requirements. The graphite of ...

Embodiment 1

[0073]Put 1g of expandable graphite (100 mesh, carbon content > 70%), 8.5g of chromium trioxide into a 100ml round bottom flask, add 7ml of concentrated hydrochloric acid (12mol / L), seal it, and add a tail gas absorption device (with chlorine gas generated , saturated NaOH absorption), the reaction system was stirred at 25°C for 10h, filtered, washed with pure water to remove unreacted concentrated hydrochloric acid and chromium trioxide, and vacuum-dried at 60°C for 12h to obtain graphite intercalation compound (GIC).

[0074] The intercalated graphite compound prepared in Example 1 of the present invention was characterized.

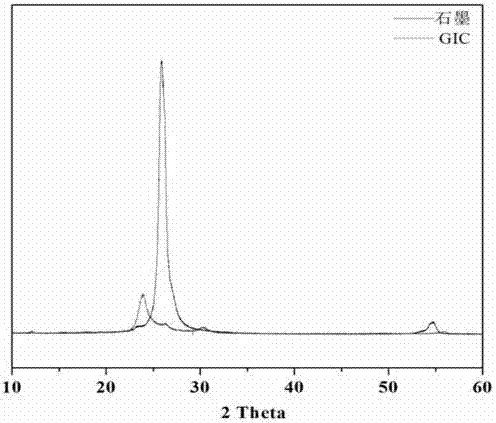

[0075] see figure 1 , figure 1 XRD diffraction patterns of the graphite used in Example 1 of the present invention and the prepared intercalated graphite compound (GIC).

[0076] From figure 1 It can be seen from the graph that the crystal structure of graphite changed significantly before and after intercalation, indicating that the intercalation w...

Embodiment 2

[0087] Put 1g of expandable graphite (50 mesh, carbon content > 75%), 5g of chromium trioxide into a 100ml round bottom flask, add 7ml of concentrated hydrochloric acid (10mol / L), seal, and add a tail gas absorption device (chlorine gas is generated, saturated NaOH absorption), the reaction system was stirred at 30°C for 5h, filtered, washed with pure water to remove unreacted concentrated hydrochloric acid and chromium trioxide, and vacuum-dried at 70°C for 6h to obtain graphite intercalation compound (GIC).

[0088] Put 0.2gGIC into 20ml of hydrogen peroxide, immerse and stand at 25°C for 24h, filter, and wash with pure water to obtain worm-like graphite aggregates (CEWG).

[0089] Finally, 0.1 g of CEWG obtained was added to 100 ml of an aqueous solution containing sodium dodecylbenzene sulfonate, wherein the concentration of sodium dodecylbenzene sulfonate was 0.2 mol / L, and ultrasonically treated at 2000 W for 2 hours to obtain graphene. After calculation and detection, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com