Pole lug aluminum strip surface treatment passivation solution

A technology of surface treatment and passivation solution, applied in the direction of metal material coating process, etc., can solve problems such as air hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

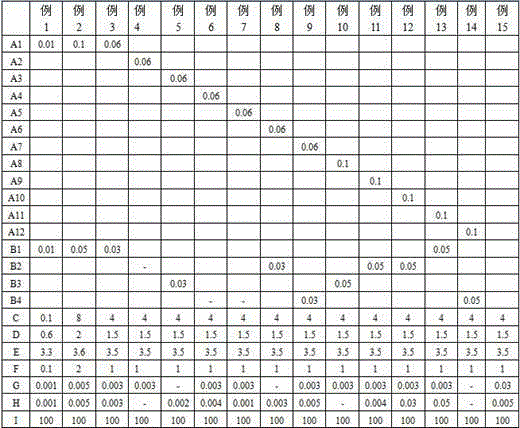

Examples

Embodiment approach

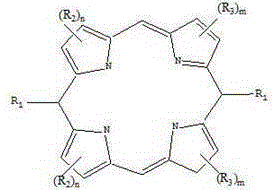

[0056] As an embodiment, the R 1 Alanine, valine, leucine, isoleucine, proline, phenylalanine, tryptophan, methionine, glycine, serine, threonine, cysteine, tyrosine , one of the residues of asparagine and glutamine.

[0057] As an embodiment, the R 1 One of residues selected from serine, tyrosine, isoleucine, threonine, and aspartic acid.

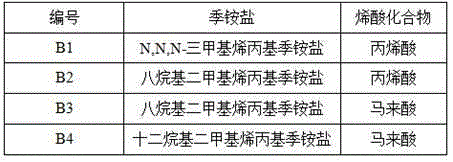

[0058] As an embodiment, the passivation solution for surface treatment of tab aluminum strips further includes a copolymer of a quaternary ammonium salt monomer and an alkenoic acid compound.

[0059]As an embodiment, the quaternary ammonium salt monomer is a quaternary ammonium salt having an alkyl group with a carbon number of 1-18 and a double bond; the enoic acid compound has at least one double bond and at least one carboxyl group compound of.

[0060] As an embodiment, the quaternary ammonium salt monomer is selected from N,N,N-trimethyl-allyl quaternary ammonium salt, dodecyldimethylallyl quaternary ammonium salt, octaalkyl di ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com