Acid-resisting alkali-resisting refractory castable for garbage incinerator

A waste incinerator, acid and alkali-resistant technology, applied in the field of refractory castables, can solve the problems of poor chemical corrosion resistance, short service life, poor thermal shock stability, etc., and achieve good chemical corrosion resistance, long service life, and high operating temperature high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The refractory, acid-resistant and alkali-resistant castable for garbage incinerators includes the following raw materials, and each raw material is combined according to the following weight parts:

[0026] Low iron sintered mullite M50 65 parts,

[0027] Boron carbide powder 10 parts,

[0028] 3 parts silicon carbide,

[0029] 8 parts of pure calcium aluminate cement,

[0030] 8 parts of chromium trioxide powder,

[0031] α-Al 2 o 3 Micropowder 4 parts,

[0032] uf-SiO 2 3 copies,

[0033] 3 parts zirconia,

[0034] Magnesium oxide 1 part,

[0035] 0.1 parts of water reducing agent,

[0036] 0.1 part of retarder,

[0037] Anti-explosion agent 0.5 part.

[0038] Add 5-6 parts of water by weight to mix and stir during construction.

Embodiment 2

[0040] The refractory, acid-resistant and alkali-resistant castable for garbage incinerators includes the following raw materials, and each raw material is combined according to the following weight parts:

[0041] Low iron sintered mullite M50 70 parts,

[0042] Boron carbide powder 5 parts,

[0043] Silicon carbide 5 parts,

[0044] 8 parts of pure calcium aluminate cement,

[0045] 5 parts of chromium trioxide powder,

[0046] α-Al 2 o 3 Micropowder 6 parts,

[0047] uf-SiO 2 3 copies,

[0048] 1 part zirconia,

[0049] Magnesium oxide 3 parts,

[0050] 0.5 parts of water reducer,

[0051] 0.05 part of retarder,

[0052] Anti-explosion agent 0.1 part.

[0053] Add 5-6 parts of water by weight to mix and stir during construction.

Embodiment 3

[0055] The refractory, acid-resistant and alkali-resistant castable for garbage incinerators includes the following raw materials, and each raw material is combined according to the following weight parts:

[0056] Low iron sintered mullite M50 68 parts,

[0057] 7 parts of boron carbide powder,

[0058] SiC 4 parts,

[0059] 7 parts of pure calcium aluminate cement,

[0060] 6 parts of chromium trioxide powder,

[0061] α-Al 2 o 3 Micropowder 5 parts,

[0062] uf-SiO 2 5 copies,

[0063] Zirconia 2 parts,

[0064] Magnesium oxide 2 parts,

[0065] 0.3 parts of water reducing agent,

[0066] 0.07 parts of retarder,

[0067] Anti-explosion agent 0.3 parts.

[0068] Add 5-6 parts of water by weight to mix and stir during construction.

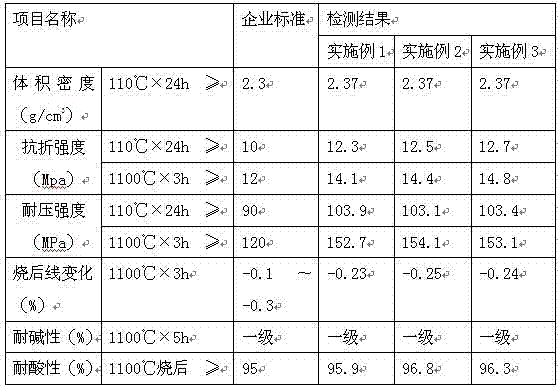

[0069] The test results of physical and chemical properties of the refractory, acid-resistant and alkali-resistant pouring for waste incinerators in the above examples are shown in the table. Since there is no national standard in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com