Nano dichromium dioxide catalyst for preparing ethylene by using carbon dioxide to oxidate ethane and dehydrogenation

A technology of chromium trioxide and ethylene oxide, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, chromium trioxide, physical/chemical process catalyst, etc., can solve the problem of insignificant decrease in reaction temperature, and achieve Narrow particle size distribution, high purity, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

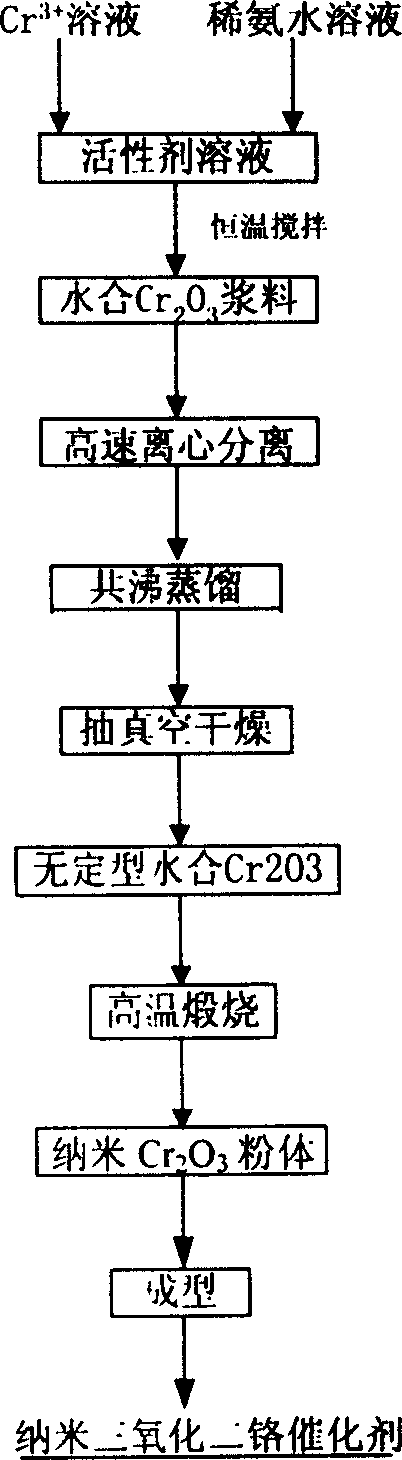

Method used

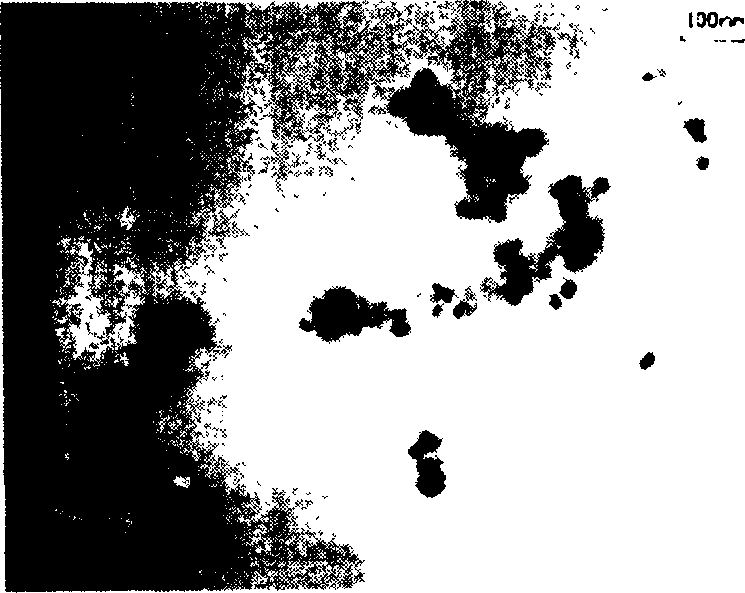

Image

Examples

Embodiment

[0018] (1)Cr(NO 3 ) 3 Solution and configuration of dilute ammonia solution

[0019] Weigh 16g Cr(NO 3 ) 3 .9H 2 O was dissolved in 200ml distilled water to form Cr(NO 3 ) 3 solution. Then ammonia water and distilled water are mixed to form a dilute ammonia solution with a concentration of 2.5 wt%.

[0020] (2) Preparation of surfactant solution

[0021] Take 5ml of oleic acid and Tween-80 and dissolve them in 200ml of prepared dilute ammonia solution; stir to obtain a translucent surfactant solution, wherein the concentration of ammonia is 1wt%.

[0022] (3) Preparation of nano slurry

[0023] In the state of constant stirring, the Cr(NO 3 ) 3 solution and dilute ammonia solution flow into the surfactant solution of step (2) at a temperature of 40°C, wherein Cr(NO 3 ) 3 The volume ratio of solution and surfactant solution is 1: 1; By regulating the flow velocity of the dilute ammonia solution of step (1), regulate the hydrated Cr that constantly obtains 2 o 3 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com