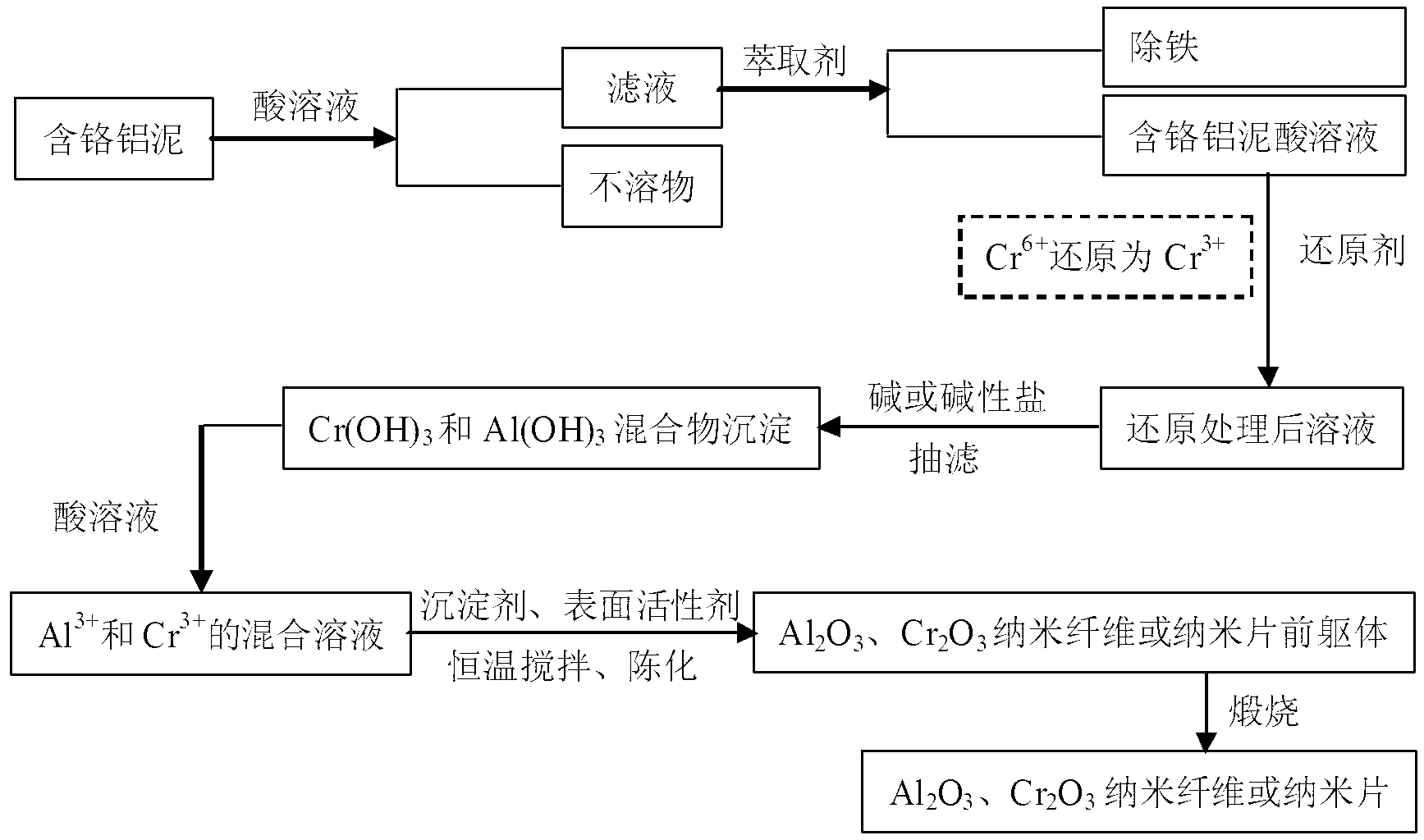

Al2O3, Cr2O3 composite nanofiber or nanosheet prepared from chromium-bearing aluminium sludge and preparation method thereof

A technology of composite nanofibers and nanosheets, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve problems such as unfavorable sustainable development of chromium salt industry, environmental pollution, waste of resources, etc. The product morphology and size are controllable, the operating cost is low, and the reaction speed is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

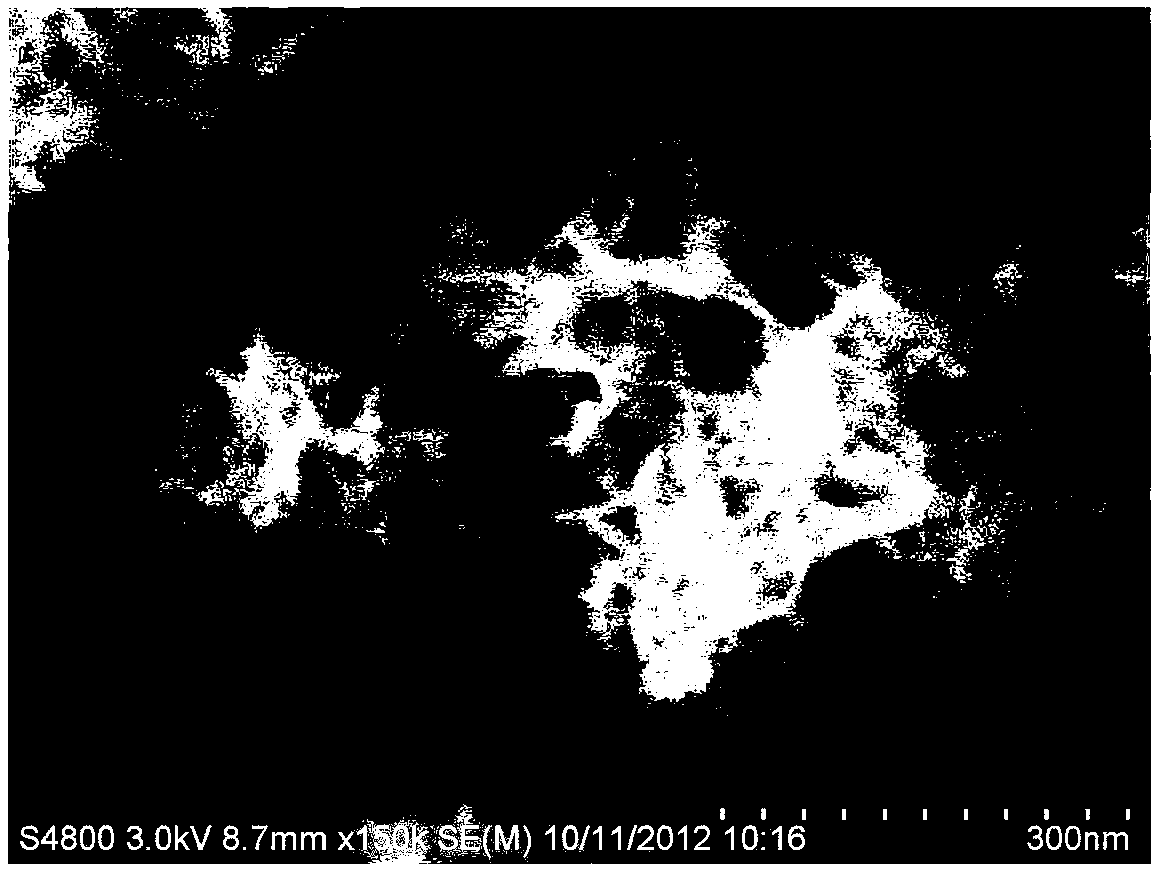

Examples

Embodiment 1

[0072] Weigh 5 g of chromium-containing aluminum slime in a beaker, add 6 mol / L H at a solid-to-liquid ratio of 1:10 2 SO 4 solution, heated to dissolve, suction filtered to remove insoluble matter, retain the filtrate to obtain an acid solution containing chrome-aluminum mud. Add Primene JMT solution to the acid solution containing chrome-aluminum mud at a volume ratio of 1:5, shake at room temperature for 20 min, and let it stand until the solution is separated and the oil phase is removed. Determination of Cr in chromium-containing aluminum mud acid solution after iron removal 6+ content, according to the Cr 6+ reduced to Cr 3+ Required H 2 o 2 1.0 times of adding H 2 o 2 solution, stirred for 60 min, Cr 6+ reduced to Cr 3+. Use 0.5 mol / L NaOH solution to adjust the pH of the chromium-containing aluminum mud acid solution to 4.0 after reduction treatment to form Al(OH) 3 and Cr(OH) 3 The mixture was precipitated, left to stand for 20 h, and filtered with suction...

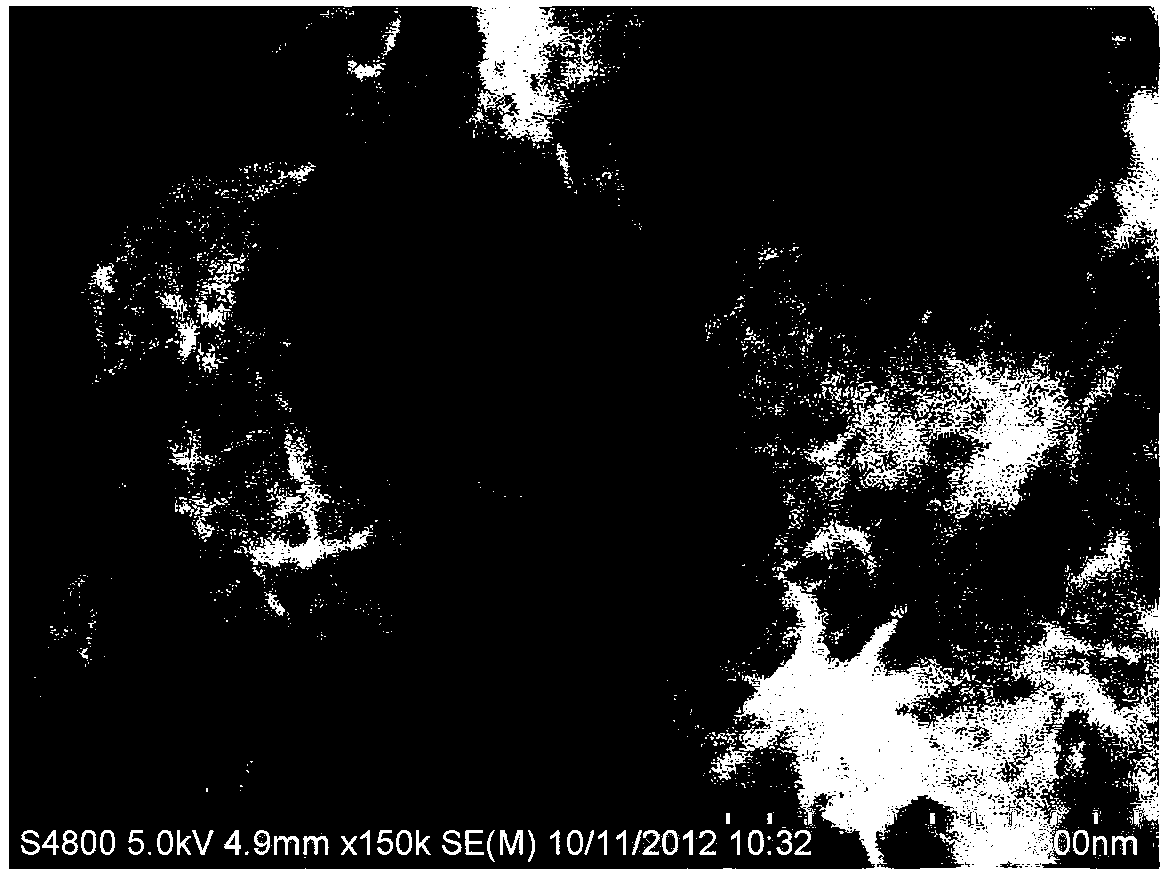

Embodiment 2

[0075] Weigh 5 g of chromium-containing aluminum slime in a beaker, add 12 mol / L H at a solid-to-liquid ratio of 1:2 2 SO 4 solution, heated to dissolve, suction filtered to remove insoluble matter, retain the filtrate to obtain an acid solution containing chrome-aluminum mud. Add TBP solution to the acid solution containing chromium-aluminum mud at a volume ratio of 1:0.1, shake at room temperature for 2 min, and let stand until the solution is separated and remove the oil phase. Determination of Cr in chromium-containing aluminum mud acid solution after iron removal 6+ content, according to the Cr 6+ reduced to Cr 3+ Required H 2 1.2 times of adding H 2 , stirring the reaction for 10 min, the Cr 6+ reduced to Cr 3+ . Use 1 mol / L NaOH solution to adjust the pH of the chromium-containing aluminic acid solution to 6.0 after reduction treatment to form Al(OH) 3 and Cr(OH) 3 The mixture was precipitated, left to stand for 0.5h, and filtered with suction to obtain Al(OH)...

Embodiment 3

[0078] Weigh 5 g of chromium-containing aluminum slime in a beaker, add 1mol / L H at a solid-to-liquid ratio of 1:50 2 SO 4 solution, heated to dissolve, suction filtered to remove insoluble matter, retain the filtrate to obtain an acid solution containing chrome-aluminum mud. Add N1923 solution to the acid solution containing chromium-aluminum mud at a volume ratio of 1:10, shake at room temperature for 60 min, and let it stand until the solution is separated and the oil phase is removed. Determination of Cr in chromium-containing aluminum mud acid solution after iron removal 6+ content, according to the Cr 6+ reduced to Cr 3+ Add ascorbic acid to 1.5 times of the required ascorbic acid, stir and react for 50 min, and Cr 6+ reduced to Cr 3+ . Use 8 mol / L KOH solution to adjust the pH=12.5 of chromium-containing aluminum mud acid solution after reduction treatment to form Al(OH) 3 and Cr(OH) 3 The mixture was precipitated, left to stand for 24h, and filtered with suctio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com