Preparation method of hydrated chromium oxide green

A chromium oxide green and hydration technology, which is applied in the field of inorganic chromium salt pigments, can solve the problems of low pigment brightness, weak hiding power, and insufficient pigment performance, and achieve bright color, better vanadium removal effect, and high pigment brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

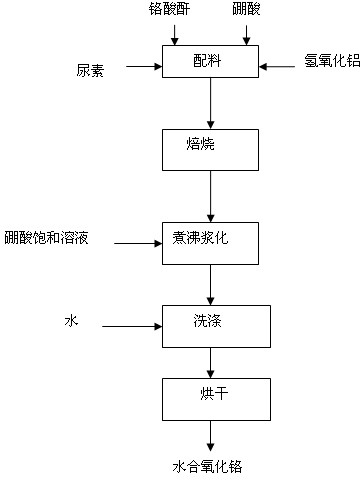

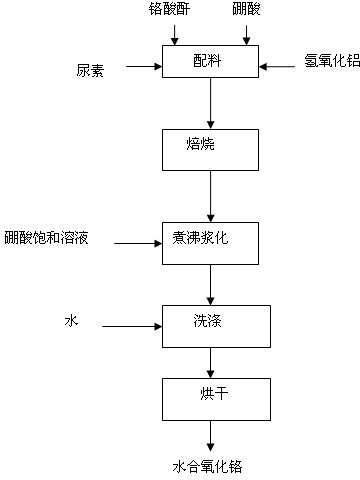

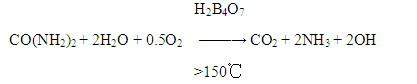

Method used

Image

Examples

Embodiment 1

[0025] (1) Ingredients

[0026] Weigh 20g of chromic anhydride (CrO 3 ≥99.5%), boric acid 80g (H 3 BO 3 ≥99%), urea 3g (H 2 NCONH 2 ≥99%), aluminum hydroxide 16g (Al(OH) 3 ≥98.5%), mix well;

[0027] (2) Roasting

[0028] Put it into a rotary kiln that has been heated to 750°C, heat-preserve and roast for 1 hour to obtain 46g of clinker;

[0029] (3) Boiling slurry

[0030] Pour 230g of boric acid saturated solution, boil at 92°C for 1 hour, and filter to obtain 68g of wet base filter cake;

[0031] (4) washing

[0032] Pour the wet-based filter cake into 102ml of water, boil at 92°C for 0.5 hours, and filter, then pour the obtained wet-based filter cake into 102ml of water again, boil at 92°C for 0.5 hours;

[0033] (5) drying

[0034] The obtained substance was dried at 75° C. for 2 hours to obtain 18 g of hydrated chromium oxide green.

[0035] The test results are shown in the table below:

[0036] Test items Hiding power g / m 2 Oil absorption g / ...

Embodiment 2

[0038] (1) Ingredients

[0039] Weigh 20g of chromic anhydride (CrO 3 ≥99.5%), boric acid 70g (H 3 BO 3 ≥99%), urea 2.5g (H 2 NCONH 2 ≥99%), aluminum hydroxide 14g (Al(OH) 3 ≥98.5%), mix well;

[0040] (2) Roasting

[0041] Put it into a resistance furnace that has been heated up to 900°C, and heat-preserve and roast for 0.5 hours to obtain 45g of clinker;

[0042] (3) Boiling slurry

[0043] Pour 270g of boric acid saturated solution, boil at 100°C for 1 hour, and filter to obtain 66g of wet-base filter cake;

[0044] (4) washing

[0045] Pour the wet base filter cake into 132ml of water, boil and slurry at 100°C for 0.5 hours, filter, pour the obtained wet base filter cake into 132ml of water again, boil and slurry at 100°C for 0.5 hours; pour the obtained wet base filter cake into 132ml of water again, Boil and slurry for 0.5 hours;

[0046] (5) drying

[0047] The obtained substance was dried at 80° C. for 3 hours to obtain 19.86 g of hydrated chromium oxide gr...

Embodiment 3

[0051] (1) Ingredients

[0052] Weigh 20g of chromic anhydride (CrO 3 ≥99.5%), boric acid 80g (H 3 BO 3 ≥99%), urea 2.5g (H 2 NCONH 2 ≥99%), aluminum hydroxide 16g (Al(OH) 3 ≥98.5%), mix well;

[0053] (2) Roasting

[0054] Put it into a resistance furnace that has been heated up to 850°C, heat-preserve and roast for 1 hour to obtain 45g of clinker;

[0055] (3) Boiling slurry

[0056] Pour 270g of boric acid saturated solution, boil at 96°C for 1 hour, and filter to obtain 65g of wet cake;

[0057] (4) washing

[0058] Pour the wet-based filter cake into 130ml of water, boil and slurry at 96°C for 1 hour, filter, and pour the obtained wet-based filter cake into 130ml of water again, and boil and slurry for 1 hour;

[0059] (5) drying

[0060] The obtained substance was dried at 80° C. for 3 hours to obtain 18 g of hydrated chromium oxide green.

[0061] The test results are shown in the table below:

[0062] Test items Hiding power g / m 2 Oil absorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com