Method of preparing chromium oxide powder using water heat reducing chromate

A chromate and chromium oxide technology, applied in the directions of chromium trioxide, chromium oxide/hydrate, etc., can solve the problems of high cost, environmental pollution, product quality, complicated process, etc., and achieves simple composition, low production cost, and technological process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

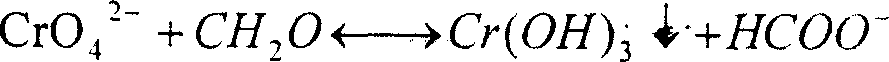

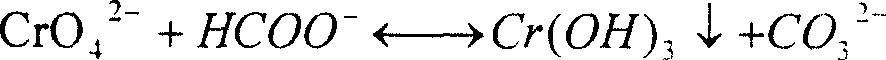

Method used

Image

Examples

Embodiment 1

[0030] 200gK 2 CrO 4 Dissolved in 800gH 2 In O, a concentration of 20 wt% K was obtained 2 CrO 4 Aqueous solution, get 85ml37wt% formaldehyde solution in addition, the consumption of formaldehyde (according to stoichiometric ratio) is 140mol% of potassium chromate in the mixed solution, and above-mentioned K 2 CrO 4 The solution is placed together in a hot-pressed reactor, and then 0.8 g of sodium dodecylsulfonate is added, mixed evenly, and the reactor is sealed and then introduced into CO 2 Gas 0.8MPa, at 600r·min -1 Raise the temperature to 160°C under high-speed stirring, stop heating after 3 hours of reaction, and open the kettle to take out the material after the temperature is lowered to below 50°C, and the hydrated Cr obtained above 2 o 3 The slurry was centrifuged at 8000rpm, the solid phase was dried at 100°C for 10 hours, then placed in a muffle furnace, calcined at 500°C for 2 hours, the calcined product was washed with water and centrifuged three times, the...

Embodiment 2

[0032] 200gK 2 CrO 4 Dissolved in 800gH 2 In O, a concentration of 20 wt% K was obtained 2 CrO 4 Aqueous solution, get 85ml37wt% formaldehyde solution in addition, the consumption of formaldehyde (according to stoichiometric ratio) is 140mol% of potassium chromate in the mixed solution, and above-mentioned K 2 CrO 4 Put the solution together in a hot-pressed reaction kettle, then add 0.8g of sodium dodecylsulfonate, mix evenly, and pass in CO after airtight 2 Gas 0.8MPa, at 600r·min -1 Raise the temperature to 160°C under high-speed stirring, stop heating after 3 hours of reaction, and open the kettle to take out the material after the temperature is lowered to below 50°C, and the hydrated Cr obtained above 2 o 3 The slurry is centrifuged at 8000rpm, the solid phase is dried at 100°C for 10 hours, then placed in a muffle furnace, calcined at 700°C for 2 hours, the calcined product is washed with water and centrifuged three times, then dried to obtain Cr 2 o 3 The prod...

Embodiment 3

[0034] 200gK 2 CrO 4 Dissolved in 800gH 2 In O, a concentration of 20 wt% K was obtained 2 CrO 4 Aqueous solution, get 85ml37wt% formaldehyde solution in addition, the consumption of formaldehyde (according to stoichiometric ratio) is 140mol% of potassium chromate in the mixed solution, and above-mentioned K 2 CrO 4 Put the solution together in a hot-pressed reaction kettle, then add 0.8g of sodium dodecylsulfonate, mix evenly, and pass in CO after airtight 2 Gas 0.8MPa, at 600r·min -1 Raise the temperature to 160°C under high-speed stirring, stop heating after 3 hours of reaction, and open the kettle to take out the material after the temperature is lowered to below 50°C, and the hydrated Cr obtained above 2 o 3 The slurry is centrifuged at 8000rpm, the solid phase is dried at 120°C for 8 hours, then placed in a muffle furnace, calcined at 1000°C for 2 hours, the calcined product is washed with water and centrifuged three times, then dried to obtain Cr 2 o 3 The prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com