Low-viscosity high-foaming type polyvinyl chloride paste resin PB110-3 and production method thereof

A technology of paste resin and polyvinyl chloride, which is applied in low-viscosity and high-foaming polyvinyl chloride paste resin PB110-3 and its production field, and can solve the technical problems of low-viscosity and high-foaming effect of polyvinyl chloride paste resin, etc. problems, to achieve the effects of reducing pollution, improving production efficiency, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

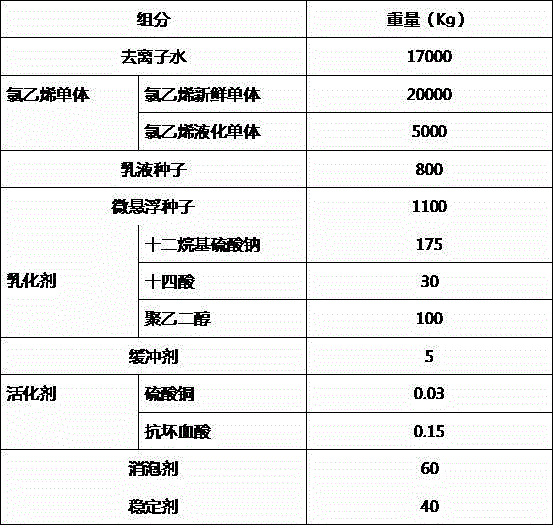

Embodiment 1

[0040] The components of low-viscosity and high-foaming polyvinyl chloride paste resin PB110-3 are as follows:

[0041]

[0042] Among them, the temperature of deionized water is 50°C, the vinyl chloride monomer is composed of fresh vinyl chloride monomer and liquefied vinyl chloride monomer, the weight of vinyl chloride monomer is 25000Kg, the weight of fresh vinyl chloride monomer and liquefied vinyl chloride monomer The ratio is 4:1, the weight of fresh vinyl chloride monomer is 20000Kg, and the weight of vinyl chloride liquefied monomer is 5000Kg.

[0043] Wherein, the emulsion seed is the latex prepared by the general emulsion polymerization method; the microsuspension seed is the latex prepared by the general microsuspension polymerization method.

[0044] Wherein, the activator is ascorbic acid and copper sulfate, the weight of the activator is 0.18Kg, the weight of ascorbic acid is 0.15Kg, the concentration of ascorbic acid is 0.15g / L~0.3g / L, the weight of copper su...

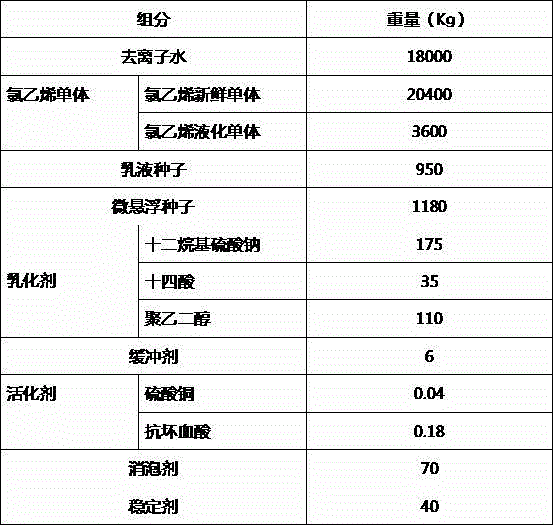

Embodiment 2

[0051] The components of low-viscosity and high-foaming polyvinyl chloride paste resin PB110-3 are as follows:

[0052]

[0053] Among them, the temperature of deionized water is 48°C, the vinyl chloride monomer is composed of fresh vinyl chloride monomer and liquefied vinyl chloride monomer, the weight of vinyl chloride monomer is 24000Kg, the weight of fresh vinyl chloride monomer is 20400Kg, and the vinyl chloride liquefied The weight of the monomer is 3600Kg.

[0054] Wherein, the emulsion seed is the latex prepared by the general emulsion polymerization method; the microsuspension seed is the latex prepared by the general microsuspension polymerization method.

[0055] Wherein, the activator is ascorbic acid and copper sulfate, the weight of the activator is 0.22Kg, the weight of ascorbic acid is 0.18Kg, the concentration of ascorbic acid is 0.18g / L~0.36g / L, the weight of copper sulfate is 0.04Kg, and the concentration of copper sulfate is 0.04Kg / L; emulsifier is sodi...

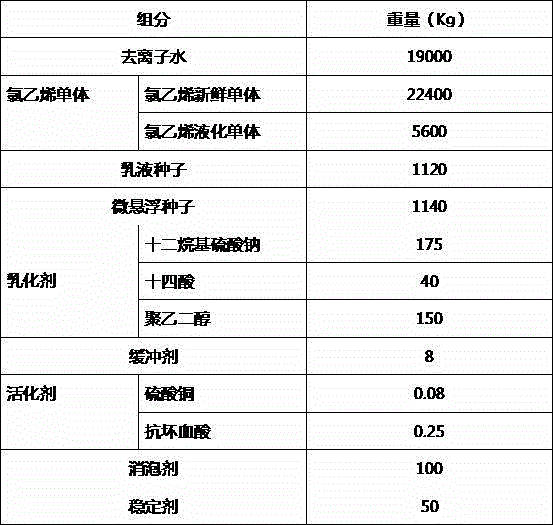

Embodiment 3

[0062] The components of low-viscosity and high-foaming polyvinyl chloride paste resin PB110-3 are as follows:

[0063]

[0064] Among them, the temperature of deionized water is 52°C, the vinyl chloride monomer is composed of fresh vinyl chloride monomer and liquefied vinyl chloride monomer, the weight of vinyl chloride monomer is 28000Kg, the weight of fresh vinyl chloride monomer and liquefied vinyl chloride monomer The ratio is 4:1, the weight of fresh vinyl chloride monomer is 22400Kg, and the weight of vinyl chloride liquefied monomer is 5600Kg.

[0065] Wherein, the emulsion seed is the latex prepared by the general emulsion polymerization method; the microsuspension seed is the latex prepared by the general microsuspension polymerization method.

[0066] Wherein, the activator is ascorbic acid and copper sulfate, the weight of the activator is 0.33Kg, the weight of ascorbic acid is 0.25Kg, the concentration of ascorbic acid is 0.25g / L~0.5g / L, the weight of copper su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com