Battery-grade cobaltosic oxide preparation method

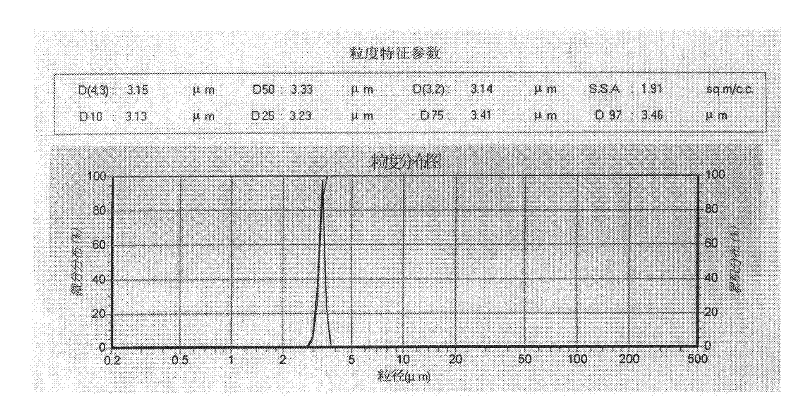

A battery-level technology of cobalt tetroxide, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of complex process, large battery volume, uneven particle size range of powder, etc., and achieve optimized preparation process, high chemical purity, and particle size distribution narrow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

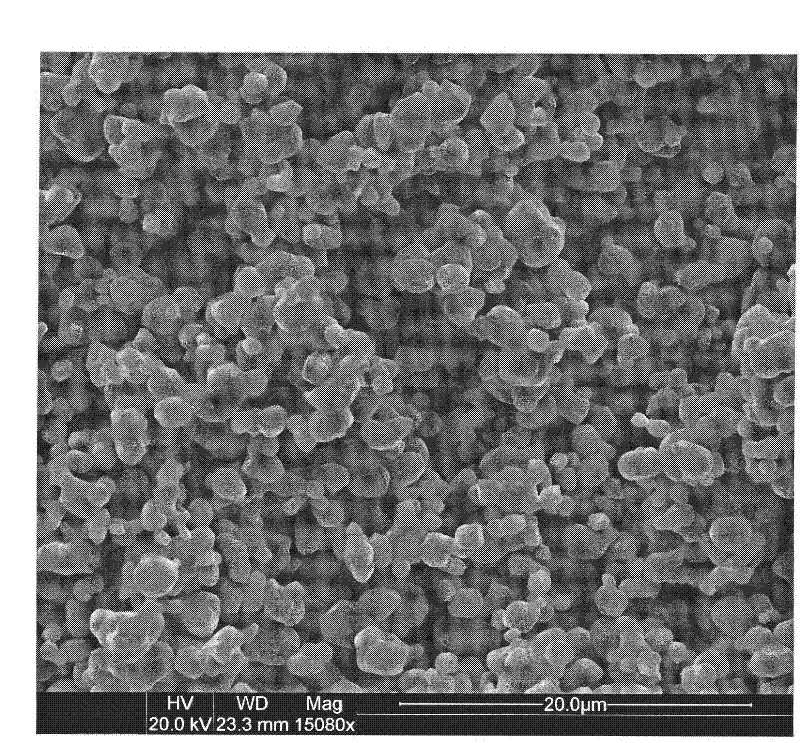

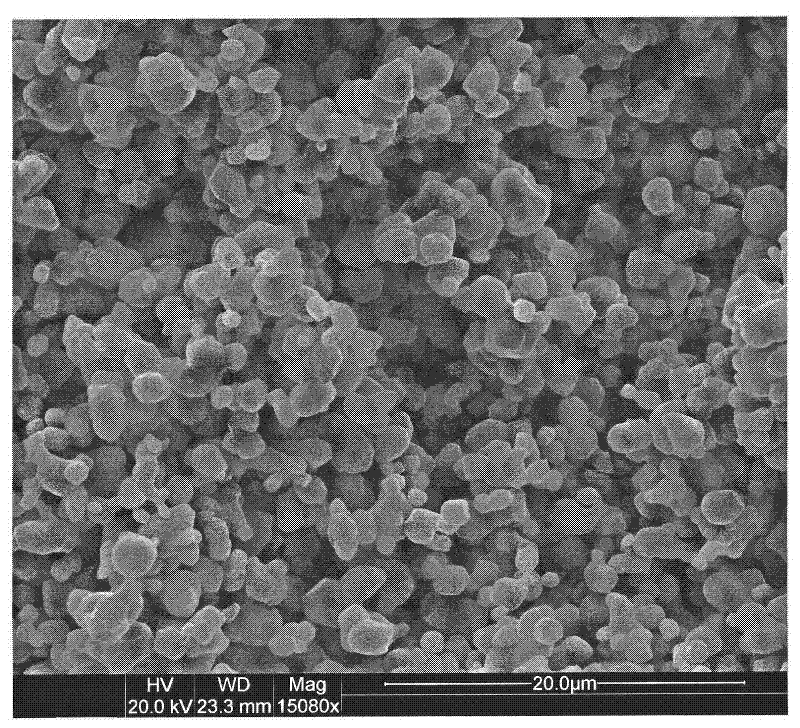

[0040] Use deionized water to prepare industrial grade cobalt sulfate into a solution with a cobalt concentration of 60g / L, and use deionized water to prepare ammonium bicarbonate into a precipitant solution with a concentration of 100g / L. Massage the cobalt solution and the precipitant solution The molar ratio, cobalt:precipitant=1.0:2.1, was added to the reaction vessel by the co-current feeding method. The addition rate of the cobalt solution and the addition rate of the precipitant solution depend on the size of the vessel to control the reaction of the precursor synthesis The temperature is 60℃, the pH value of the reaction is 7.0, the stirring speed is 300rpm, and the reaction time is as follows. The precursor is prepared by homogeneous crystallization precipitation method. The precursor is washed 3 times with deionized water at 80℃ and dehydrated. The water content of the filter cake It is 25%, directly filled into the bowl, sent to the roasting furnace at 250℃~800℃, roas...

Embodiment 2

[0042] Use deionized water to prepare industrial-grade cobalt nitrate into a solution with a cobalt concentration of 80g / L, use deionized water to prepare ammonium carbonate into a precipitant solution with a concentration of 80g / L, and massage the cobalt solution and the precipitant solution The ratio, cobalt:precipitant=1.0:3.0, was added to the reaction vessel by the co-current feeding method, the reaction temperature of the precursor synthesis was controlled to be 80°C, the reaction pH value was 8.5, the stirring speed was 500rpm, and the reaction time was 15 hours. The precursor is prepared by the phase crystallization precipitation method. The precursor is washed with deionized water at 90°C for 5 times and then dehydrated. The filter cake has a water content of 24%. It is directly filled into a bowl and sent to a roaster for 10 hours at 300°C to 900°C. , Naturally cooled to below 400 ℃ and out of the furnace, down to room temperature, after crushing and classification, th...

Embodiment 3

[0044] Use deionized water to prepare industrial-grade cobalt chloride into a solution with a cobalt concentration of 70g / L, use deionized water to prepare sodium carbonate into a precipitant solution with a concentration of 100g / L, and massage the cobalt solution and the precipitant solution The molar ratio, cobalt:precipitant=1.0:3.8, was added to the reaction vessel by the co-current feeding method, the reaction temperature of the precursor synthesis was controlled to 100°C, the reaction pH value was 9.0, the stirring speed was 500rpm, and the reaction time was 8 hours. The precursor was prepared by the homogeneous crystallization precipitation method. The precursor was washed with deionized water at 100°C for 5 times and then dehydrated. The filter cake had a water content of 24%. It was directly loaded into a bowl and sent to a roasting furnace for roasting at 300°C to 1000°C. After hours, it is naturally cooled to below 400 ℃ and out of the furnace. After being smashed and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com