Semiconductor materials and methods of producing them

A semiconductor and fuel component technology, applied in metal material coating process, thin material processing, coating and other directions, can solve the problems of strong electron amplification, difficult to manufacture diodes, and expensive to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

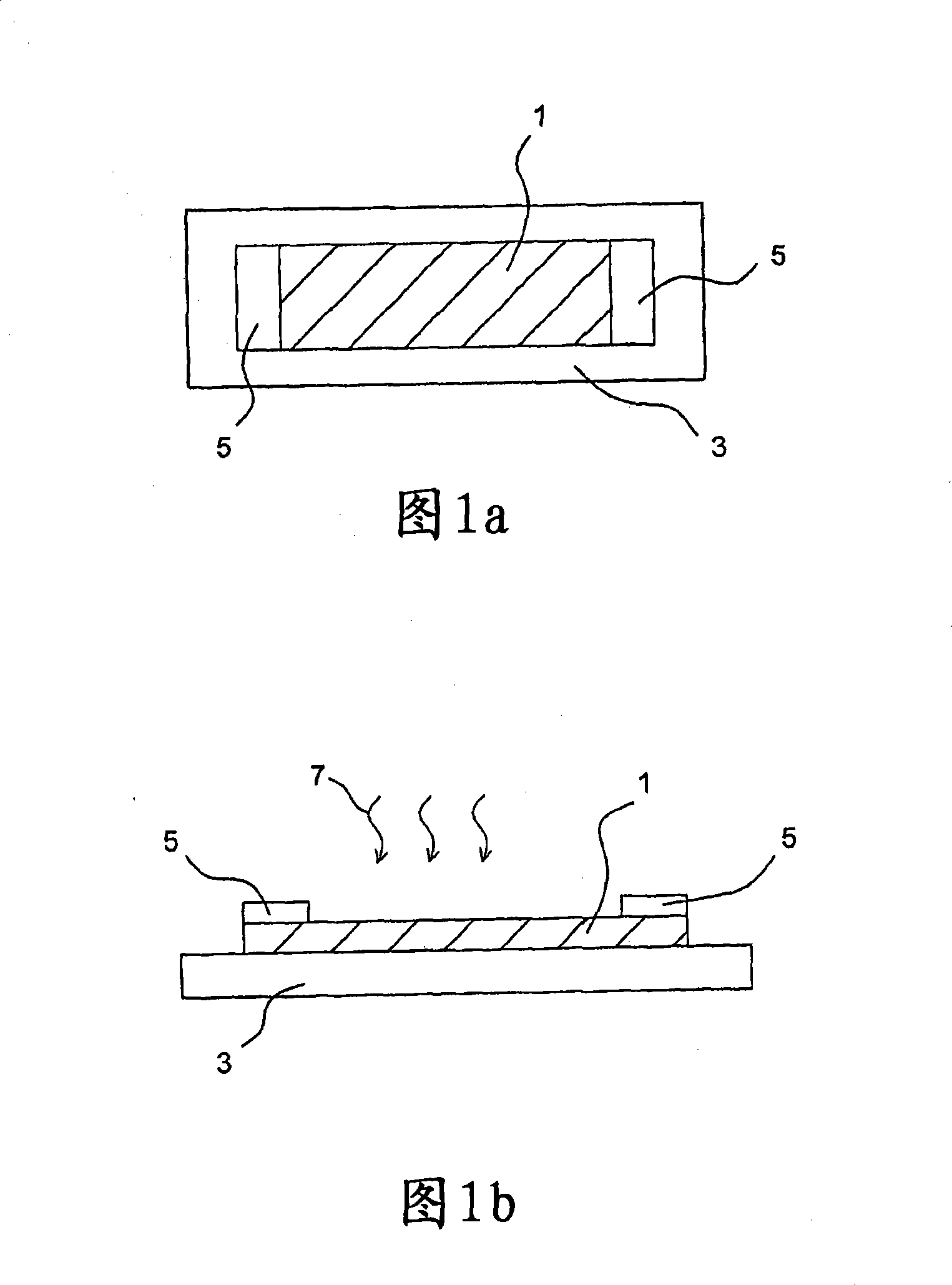

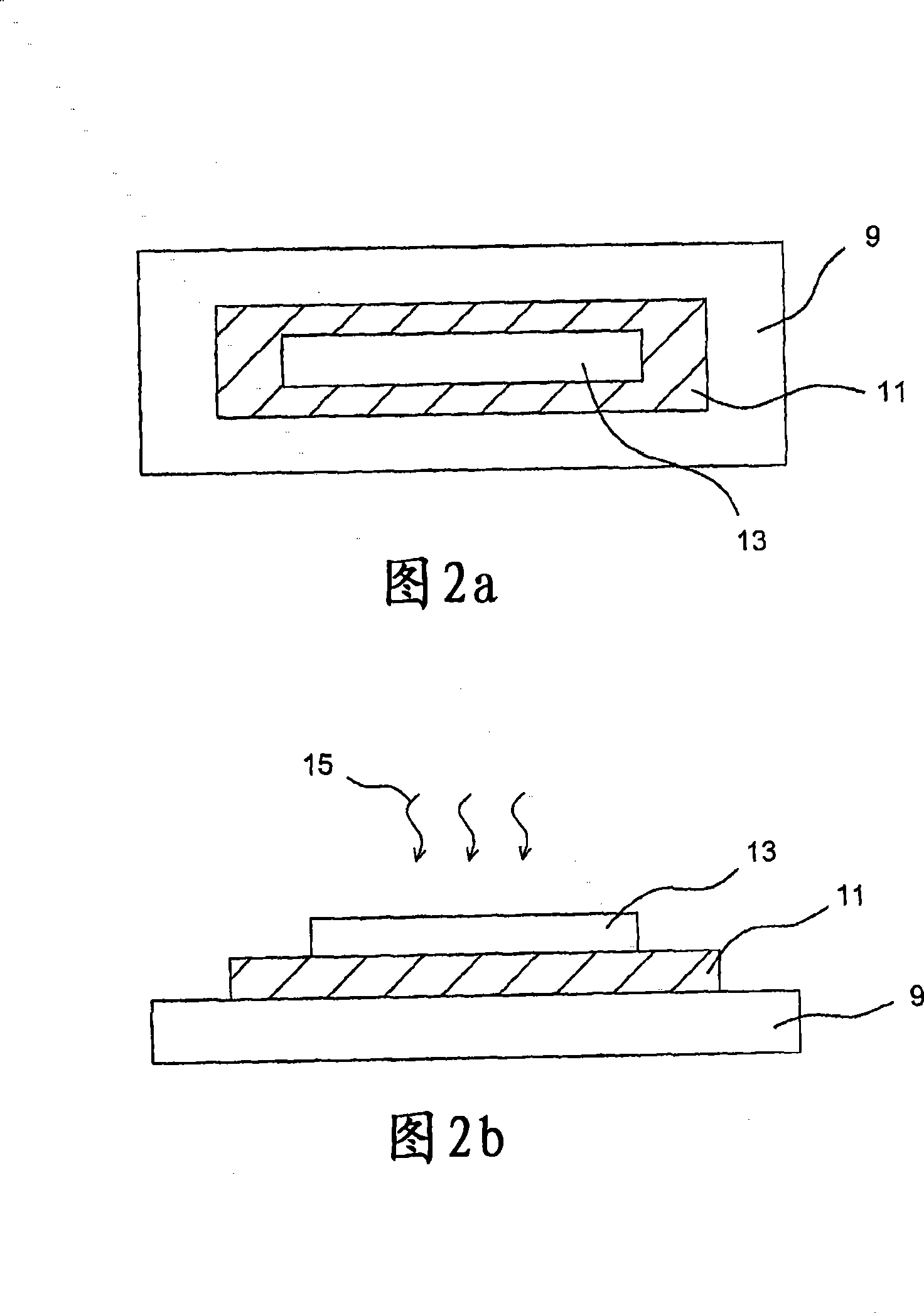

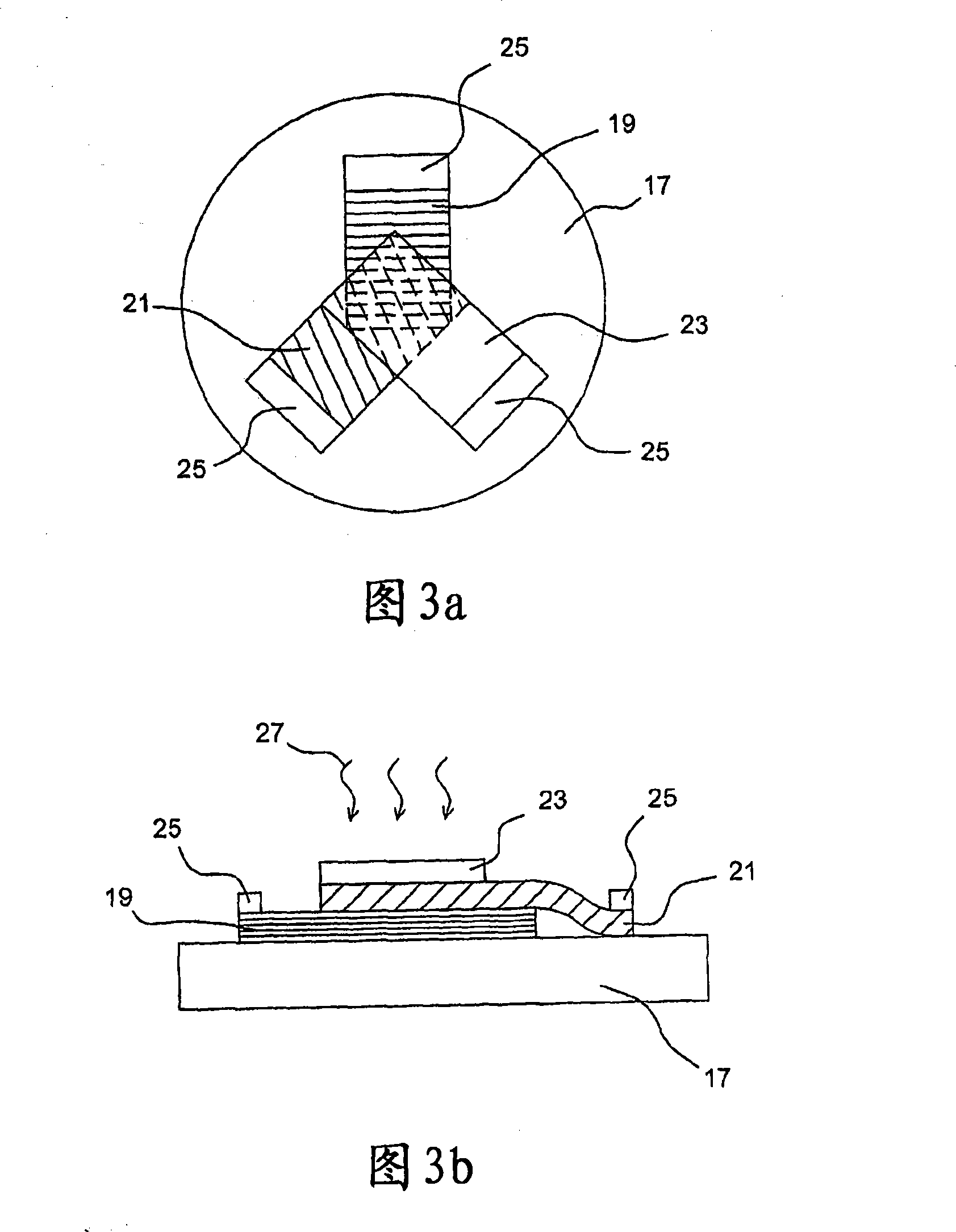

[0198] Figures 1-4 illustrate single-layer and multi-layer diode radiation detection devices, the general structure of which is known in the art, but is also an example of the structure of a radiation detection device according to an embodiment of the present invention.

[0199]FIG. 1 shows a single-layer wide bandgap detection device 1 on a substrate 3 . Contacts 5 are located at both ends of the single layer 1 . In use, a voltage is applied across the junction 5 such that a current is sensed in the external circuit when incident radiation 7 generates charge carriers within the monolayer 1 . In the prior art, the single layer 1 may be, for example, a NaI single crystal. In an embodiment of the present invention, the single layer 1 may be an n-type or p-type metal oxide, for example, a transition metal oxide. Preferably, the metal oxide particles have a metal core and an outer oxide shell, and more preferably have a degree of oxidation of 18 to 25 wt%.

[0200] The single l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com