Supercritical fluid circulating cooling method and device

A supercritical fluid and circulating cooling technology, which is applied in the field of precision parts processing and cooling, can solve the problems of inability to meet the cooling process requirements of precision workpieces, low cooling capacity, and low uniformity of workpiece cooling, achieving significant environmental benefits and improving utilization. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

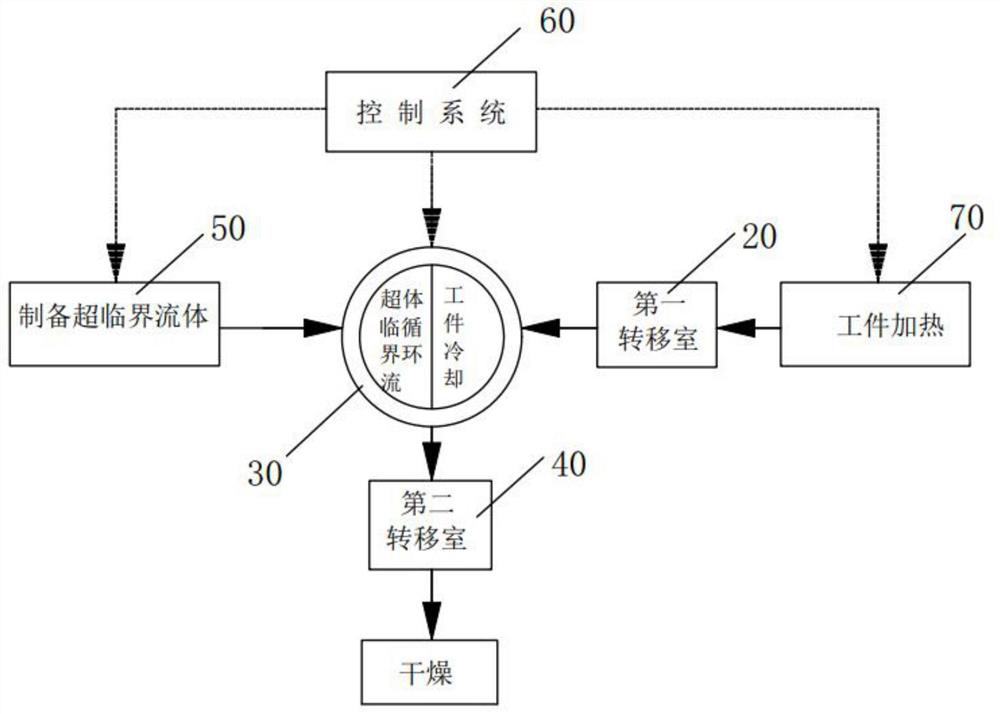

[0039] see figure 1 As shown in the process flow chart, this embodiment provides a supercritical fluid circulation cooling method for small and micro-sized precision devices, which specifically includes steps:

[0040] S1, providing an annular closed cavity 30 as a cooling treatment chamber for workpieces, passing supercritical fluid into it through a supercritical fluid supply system 40, and making the supercritical fluid flow in the Circulating flow in a closed cavity;

[0041] S2, the workpiece is sent to the conveyor belt 31 in the airtight cavity 30 through the feed transfer chamber 20, and the workpiece 10 moves along with the conveyor belt 31 along the airtight cavity 40, and the moving direction is the same as that of the airtight cavity 30. The flow direction of the supercritical fluid inside is opposite, so that the workpiece and the circulating supercritical fluid perform convective heat exchange, and the workpiece is cooled;

[0042] S3, transfer the cooled workp...

Embodiment 2

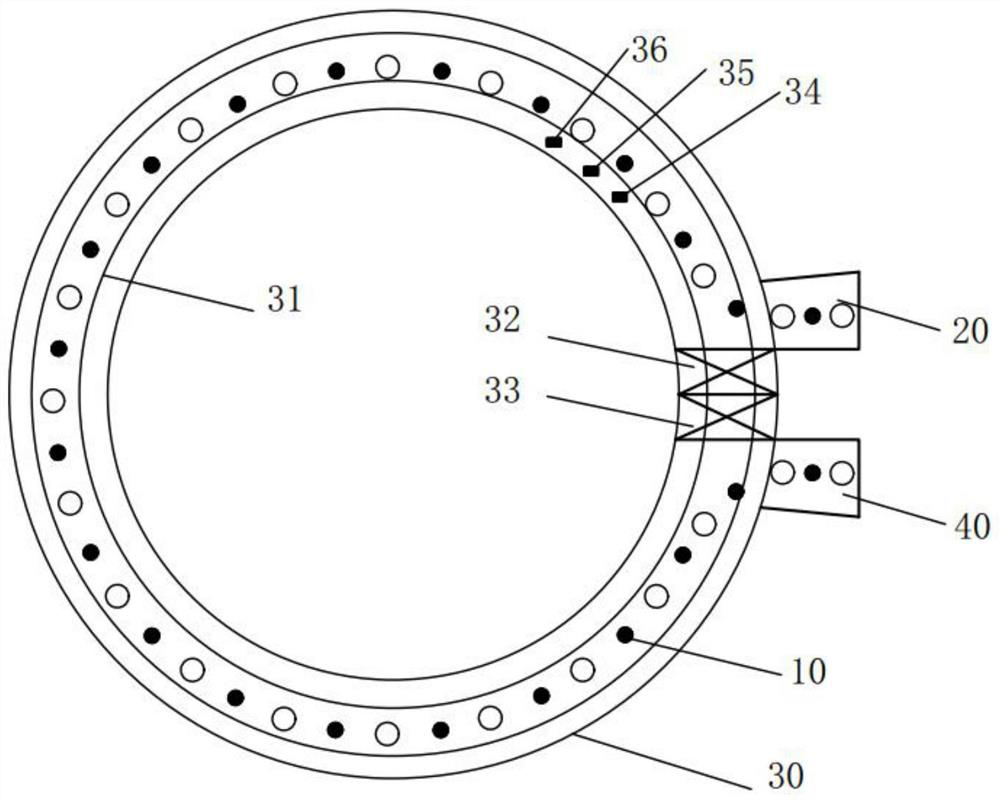

[0051] see figure 2 As shown, the present embodiment provides a supercritical fluid circulation cooling device, comprising: an annular closed cavity 30, the closed cavity 30 has a certain pressure resistance and low temperature resistance, and is provided with a transmission for the workpiece 10. An endless conveyor belt 31 ; a supercritical fluid supply system 40 , which communicates with the closed cavity 30 to supply supercritical fluid into the closed cavity 30 . The workpiece 10 is transferred from one end to the endless conveyor belt 31 from the outside, and moves circularly with the endless conveyor belt 31, and finally transfers to the outside from the tail end of the endless conveyor belt 31. In the process of circular circulation, the supercritical fluid flowing countercurrently with the closed cavity 316 conducts convective heat exchange to complete the cooling of the workpiece 10 . When using the supercritical fluid circulation cooling device to cool the workpiec...

Embodiment 3

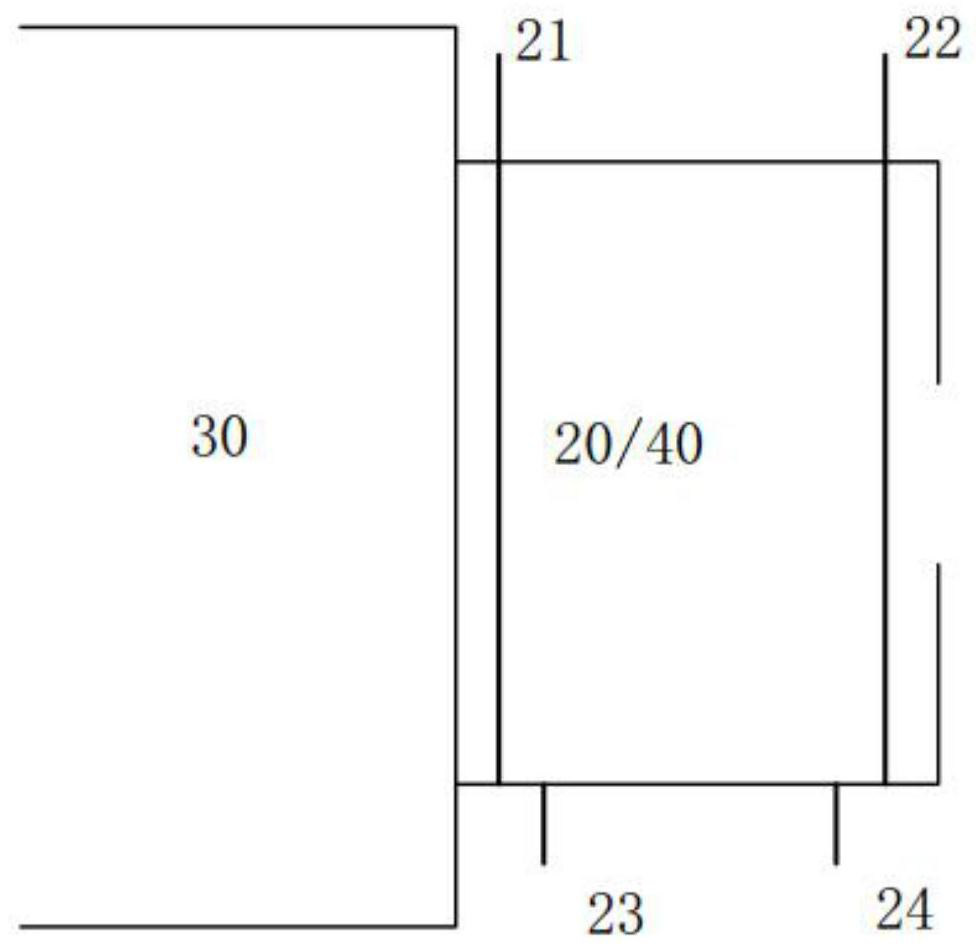

[0056] see image 3 As shown, this embodiment provides a feed transfer chamber 20 and the discharge transfer chamber that can keep the pressure and temperature of the supercritical fluid in the closed cavity 30 in a balanced state during the process of workpiece feeding and discharging. 40. The feed transfer chamber 20 and the discharge transfer chamber 40 adopt a special structural design. When the workpiece 10 enters the closed cavity 30 through the feed transfer chamber 20 or is transferred out of the discharge transfer chamber 40 from the closed cavity 30, the workpiece 10 The entry and exit of the closed cavity 30 has little influence on the supercritical state.

[0057] In this embodiment, the supercritical cooling process of the workpiece is carried out under high pressure, in order to realize the rapid, stable and safe entry and exit of the workpiece 10 into and out of the closed cavity 30 . A specific transfer chamber structure has been designed, the structure and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com