Cleaning type preparation method for medicinal basic magnesium carbonate

A technology of clean production and magnesium carbonate, applied in the direction of magnesium carbonate, etc., can solve the problems of high production cost, low environmental benefit, low economic efficiency, etc., and achieve the effect of low production cost, simple production process and clean production process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

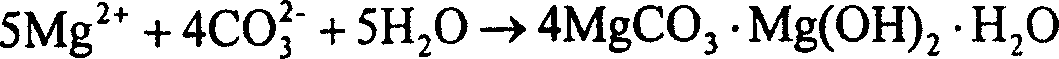

Method used

Image

Examples

Embodiment 1

[0018] Mix bittern and condensate in a volume ratio of 3:4, add 30ml of bittern to a 250ml beaker, heat to 50°C, then slowly add 40m1 of condensate, stir, boil for 3min, cool and age for 24 hours, heat washed with deionized water, and dried at 120° C. for 6 hours to obtain 5.34 g of the product, with a yield of 85.3%.

Embodiment 2

[0020] Mix bittern and condensate in a volume ratio of 3:4, add 30ml of bittern to a 250ml beaker, heat to 60°C, then slowly add 40ml of condensate, stir, continue heating for 60min, cool and age for 24 hours, use Washed with hot deionized water and dried at 120° C. for 6 hours to obtain 5.46 g of product with a yield of 87.2%.

Embodiment 3

[0022] Mix bittern and condensate in a volume ratio of 3:4, add 30ml of bittern to a 250ml beaker, heat to 70°C, then slowly add 40ml of condensate, stir, continue heating for 60min, boil for 3min after heating, cool and Aged for 24 hours, washed with hot deionized water, and dried at 120° C. for 6 hours to obtain 5.4 g of the product with a yield of 86.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com