Waterborne rusty coating for protecting coating of steel-structure work pieces and preparation method thereof

A technology for rusty coatings and steel structures, applied in the direction of anti-corrosion coatings, coatings, etc., can solve problems such as large environmental pollution, high energy consumption, and unsafety, and achieve the effects of environmental friendliness, good leveling, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

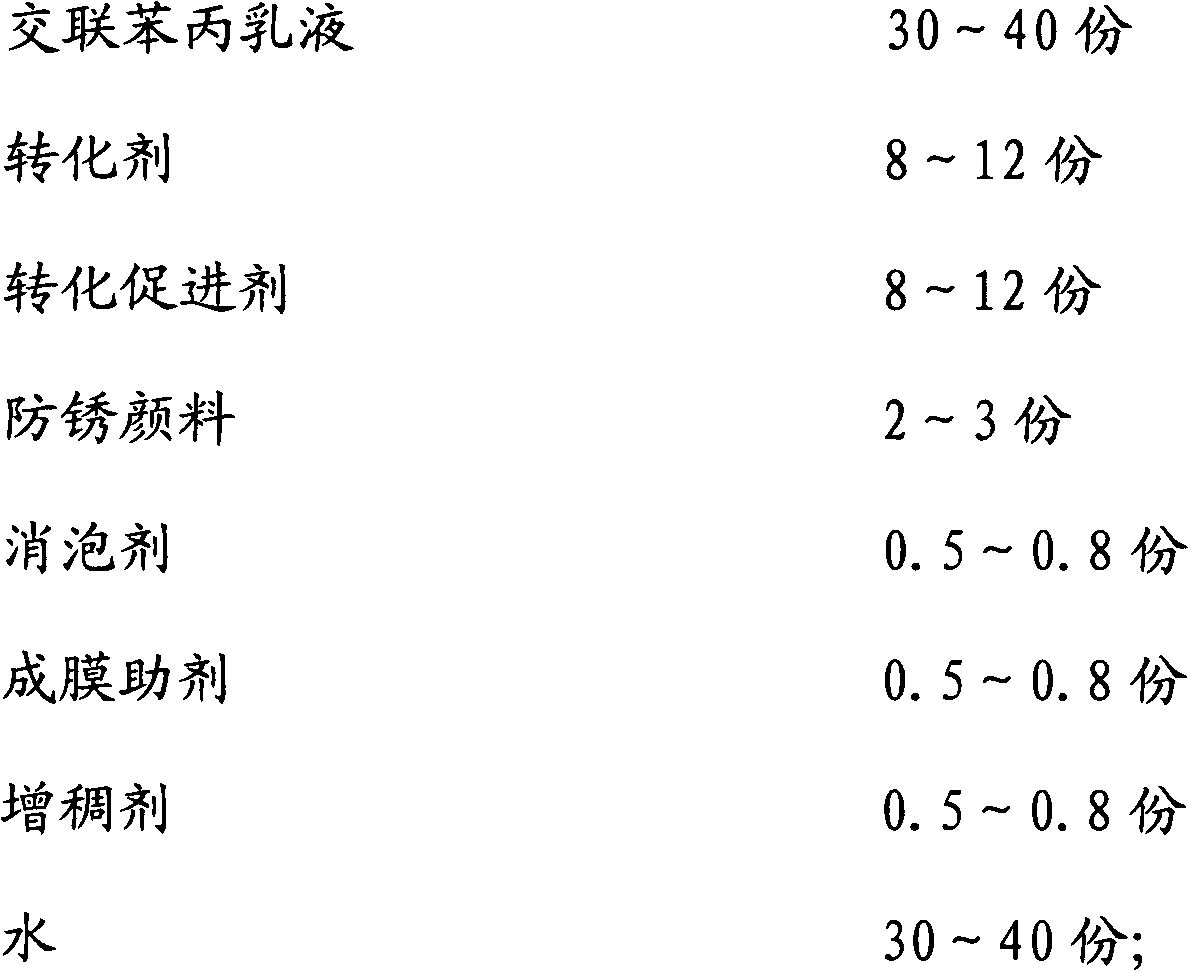

[0024] The water-based rust-bearing paint used for coating protection of steel structure workpieces, its raw materials are composed of the following weight ratio:

[0025]

[0026] Among them, the cross-linked styrene-acrylic emulsion adopts commercial grade (solid content is 44%), the conversion agent is selected oxalic acid, the anti-rust pigment is aluminum dihydrogen tripolyphosphate, the film-forming aid is ethylene glycol ether, and the thickener is commercially available. Sales grade.

[0027] The preparation steps are as follows:

[0028] ①. Mix the anti-rust pigment with 80g of water and grind to disperse to a fineness of 20 microns.

[0029] ② Add cross-linked styrene-acrylic emulsion, conversion agent, quinone, tributyl phosphate, film-forming aid, thickener and the rest of water, stir evenly, and pack to obtain the coating protection for steel structure workpieces Water-based rust paint.

Embodiment 2

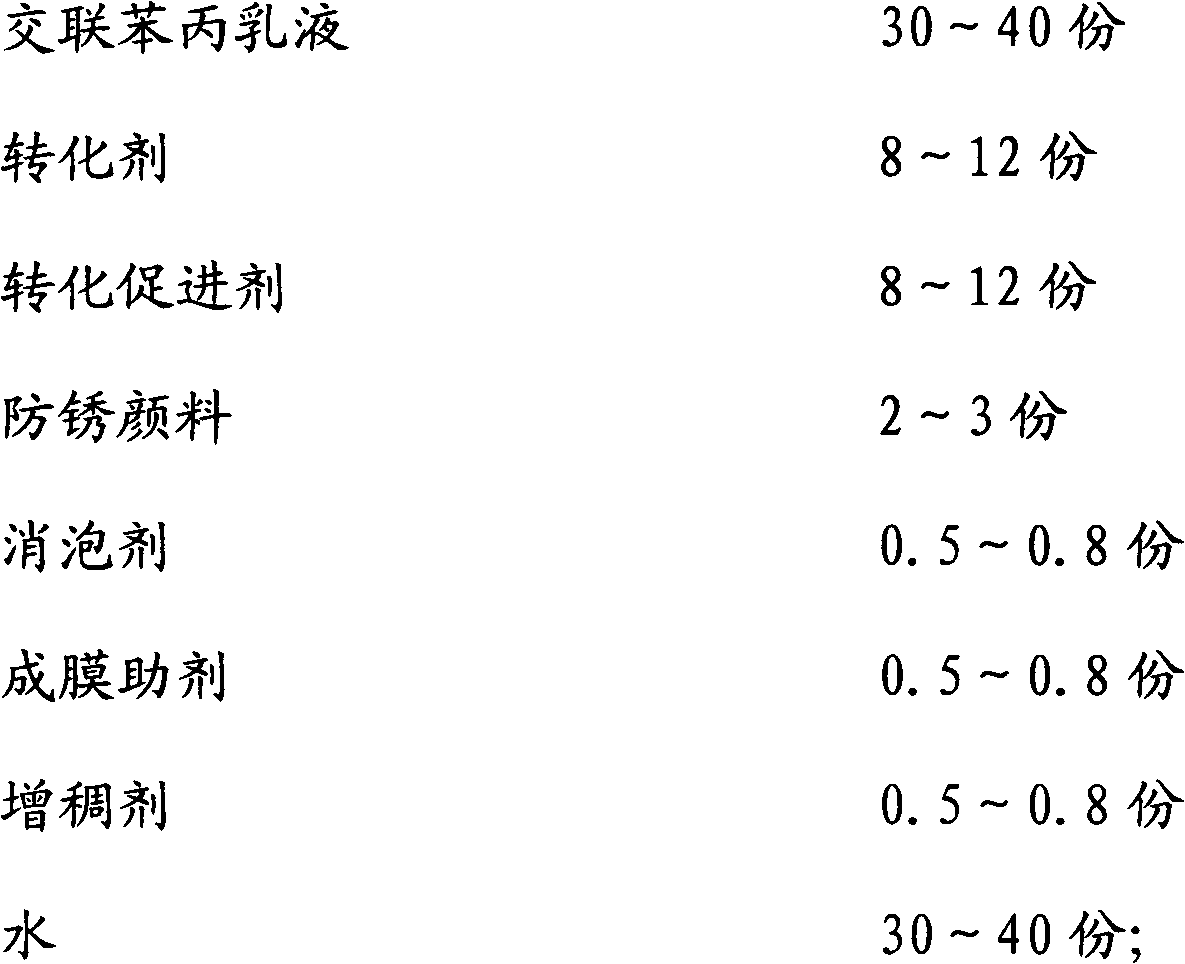

[0031] The water-based rust-bearing paint used for coating protection of steel structure workpieces, its raw materials are composed of the following weight ratio:

[0032]

[0033]

[0034] Among them, salicylic acid is selected as the conversion agent, zinc yellow is used as the anti-rust pigment, ethylene glycol propyl ether is used as the film-forming aid, and commercially available grade is used as the thickener.

[0035] The preparation steps are as follows:

[0036] ①. Preparation of cross-linked styrene-acrylic emulsion

[0037] With 50g butyl acrylate as soft monomer, 42g styrene as hard monomer, 3g N-methylol acrylamide, 3g acrylic acid as modified component, 2.4g OP-10 as emulsifier, ammonium persulfate as initiator , prepared by semi-continuous emulsion polymerization, the polymerization temperature is 78°C, the polymerization time is 2.5 hours, and the solid content of the obtained cross-linked styrene-acrylic emulsion is 45%.

[0038] ②. Mix the anti-rust ...

Embodiment 3

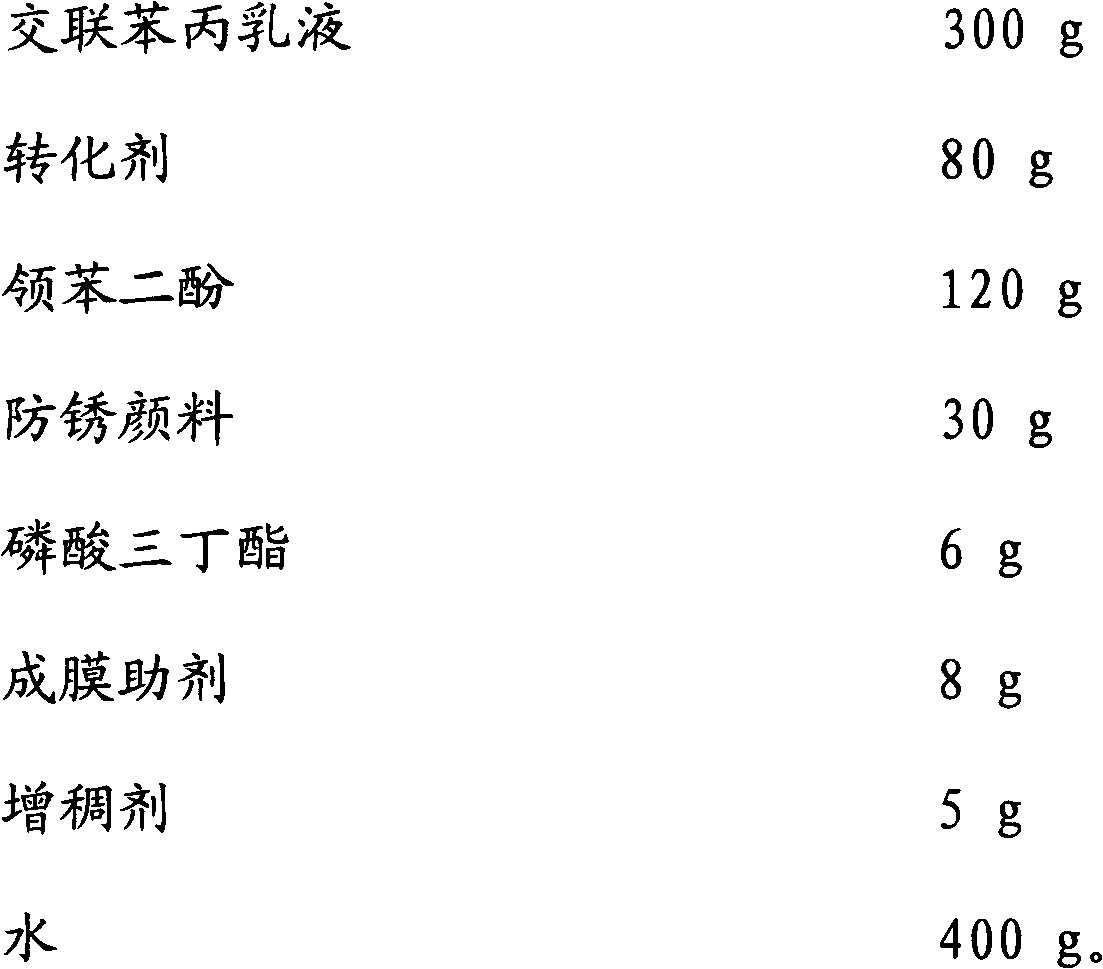

[0041] The water-based rust-bearing paint used for coating protection of steel structure workpieces, its raw materials are composed of the following weight ratio:

[0042]

[0043]

[0044] Among them, the conversion agent is oxalic acid, the antirust pigment is iron red, the film-forming aid is ethylene glycol ether, and the thickener is commercial grade.

[0045] The preparation steps are as follows:

[0046] ①. Preparation of cross-linked styrene-acrylic emulsion

[0047] With 540g butyl acrylate as soft monomer, 440g styrene as hard monomer, 33g N-methylol acrylamide, 40g acrylic acid as modified component, 23g OP-10 as emulsifier, ammonium persulfate as initiator, It is prepared by semi-continuous emulsion polymerization, the polymerization temperature is 80°C, and the polymerization time is 3 hours. The solid content of the obtained cross-linked styrene-acrylic emulsion is 46%.

[0048] ②. Mix the anti-rust pigment with 120g of water and grind to disperse to a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com