Aqueous normal temperature curing peelable paint and preparation method of paint

A room temperature curing and coating technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor barrier performance of single-component film-forming materials, poor environmental performance of solvent-based peelable and sealed coatings, etc., to achieve Good stripping performance, moderate matrix bonding force, and uniform film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

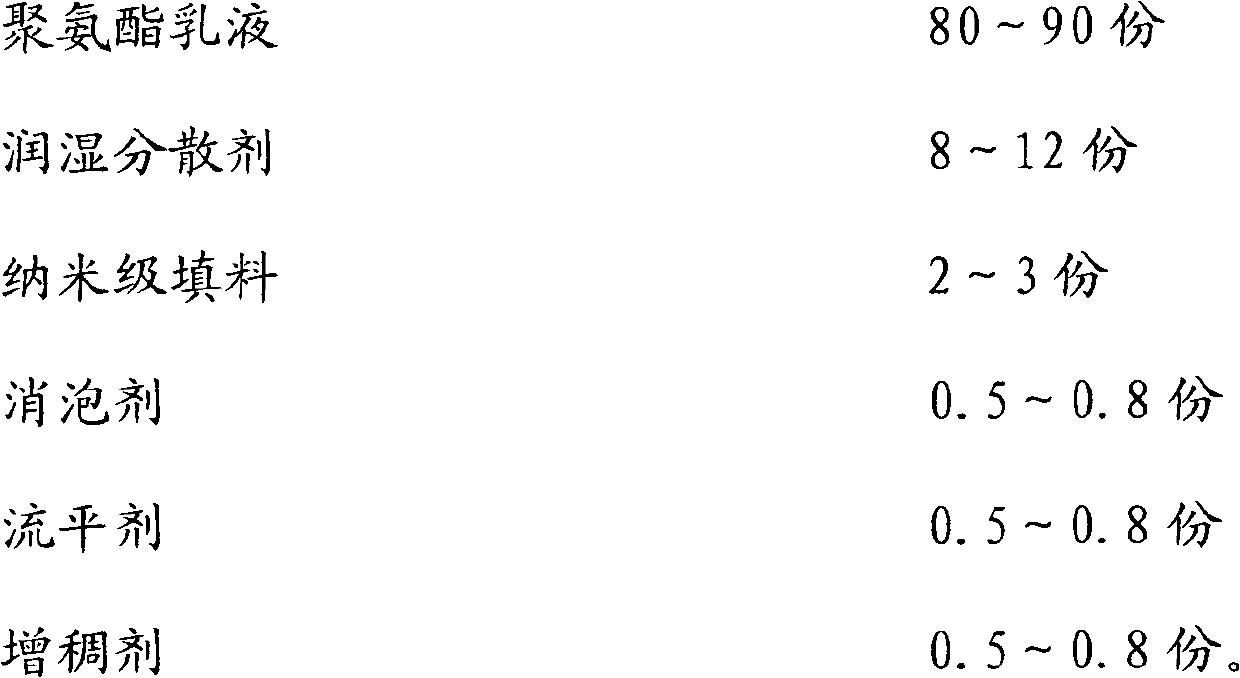

[0025] A water-based room temperature curing peelable coating is composed of the following raw materials in weight ratio:

[0026]

[0027]

[0028] Wherein, the wetting and dispersing agent is an anionic multifunctional polymer alkoxide ammonium salt solution.

[0029] Polyurethane emulsion contains carboxyl group or sulfonate chain extension to introduce carboxyl group or sulfonate ion anion type, solid content is 50±1%, pH value is 7.5±0.5, emulsion particle size is not more than 200nm, glass transition temperature range -25~- 5°C.

[0030] The nano-scale filler is nano-calcium carbonate with an average particle size of 40nm, the defoamer is a mixture of silicone-free hydrophobic solid and foam-breaking polymer, and the leveling agent is polyether-modified polydimethylsiloxane Copolymer solvent, thickener is modified urea polyurethane solution.

[0031] The preparation method of water-based room temperature curing peelable coating, the steps are as follows:

[0032...

Embodiment 2

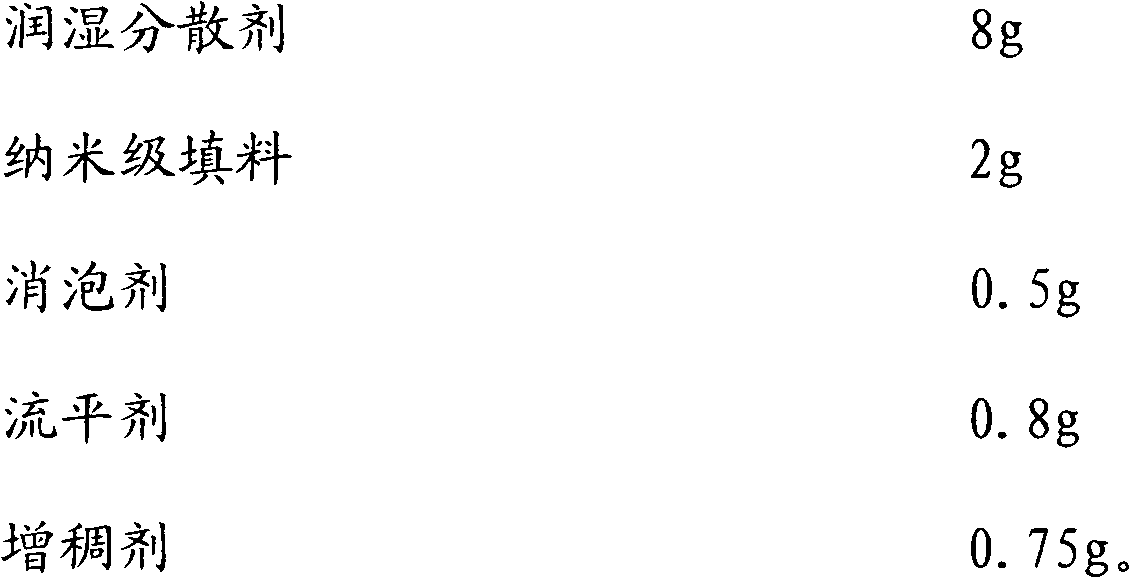

[0034] A water-based room temperature curing peelable coating is composed of the following raw materials in weight ratio:

[0035]

[0036]

[0037] Wherein, the wetting and dispersing agent is acrylate copolymer ammonium salt solution.

[0038] Polyurethane emulsion, nano filler, defoamer, leveling agent and thickener are the same as in Example 1.

[0039] The preparation method of water-based room temperature curing peelable coating, the steps are as follows:

[0040] Under the condition of stirring at 1500rpm, add nano-scale fillers to the polyurethane emulsion with wetting and dispersing agent, disperse for 2 hours with a sand mill, disperse, and stir multipurpose machine, then add defoamer, leveling agent and thickener in sequence, and disperse Serve evenly.

Embodiment 3

[0042] A water-based room temperature curing peelable coating is composed of the following raw materials in weight ratio:

[0043]

[0044] Wherein, the wetting and dispersing agent is an anionic polyfunctional polymer alkoxide ammonium salt solution and an acrylate copolymer ammonium salt solution, and the weight ratio of the two is 1:1.

[0045] Polyurethane emulsion, nano filler, defoamer, leveling agent and thickener are the same as in Example 1.

[0046] The preparation method of water-based room temperature curing peelable coating, the steps are as follows:

[0047] Under the condition of stirring at 1300rpm, add nano-scale fillers to the polyurethane emulsion with wetting and dispersing agent, disperse for 2.2 hours with a sand mill, disperse, and stir multipurpose machine, and then add defoamer, leveling agent and thickener in sequence, Get it after it is evenly dispersed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com