A heating method for assembly and molding of middle-connected terminals

A heating method and terminal technology, which is applied in the assembly/disassembly of contact parts, connection insulation, etc., can solve the problems of brittle heat-shrinkable tubes, low yield, and environmental protection, and achieve the effect of improving the production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

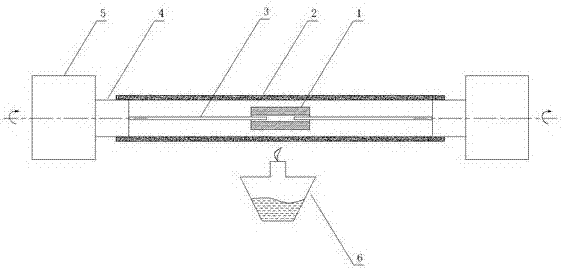

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] The invention provides a heating method for assembling and molding intermediate terminals. The method is to fix both ends of the heat-shrinkable tube 2 covered with the copper sleeve 1 and then rotate synchronously, and introduce a heat source under the heat-shrinkable tube where the copper sleeve is located for heating.

[0014] The present invention uses clean energy for heating, and the heat source is an alcohol lamp 6 .

[0015] Synchronous rotation of the present invention adopts synchronous rotation of different shafts.

[0016] see figure 1 , the heating method of the present invention is: connect the two ends of the heat-shrinkable tube 2 with the copper sleeve 1 to the motor 5 with the thimble 3 respectively, one end of the thimble 3 is inserted into the copper sleeve 2, and the other end of the thimble 3 is provided with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com