Double-open type hollow profile frame stretch bending forming method

A stretch-bending, double-opening technology, applied in the field of plastic processing, can solve the problems of deformation control, increased feeding and filling, unpredictable part forming accuracy, etc., and achieves improved tensile rigidity, less manual trimming, and less springback. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

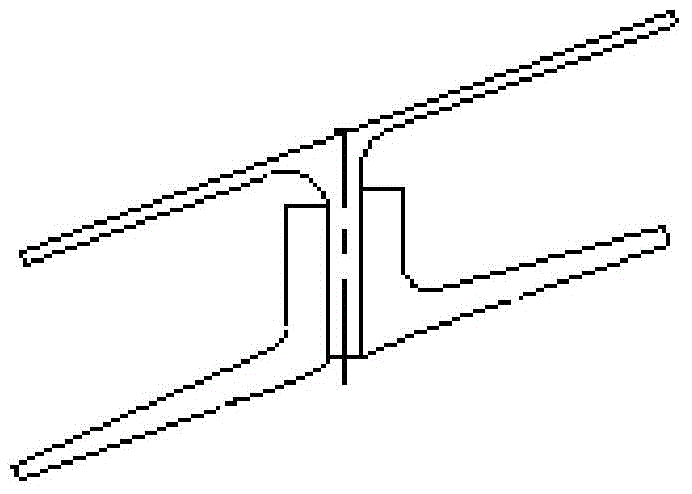

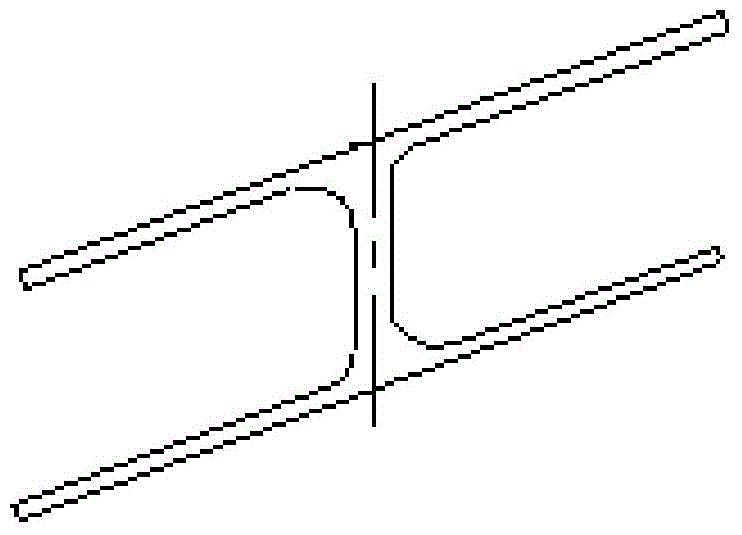

[0047] The invention mainly utilizes the stretch bending forming process to realize the manufacture of double open hollow profile frame parts.

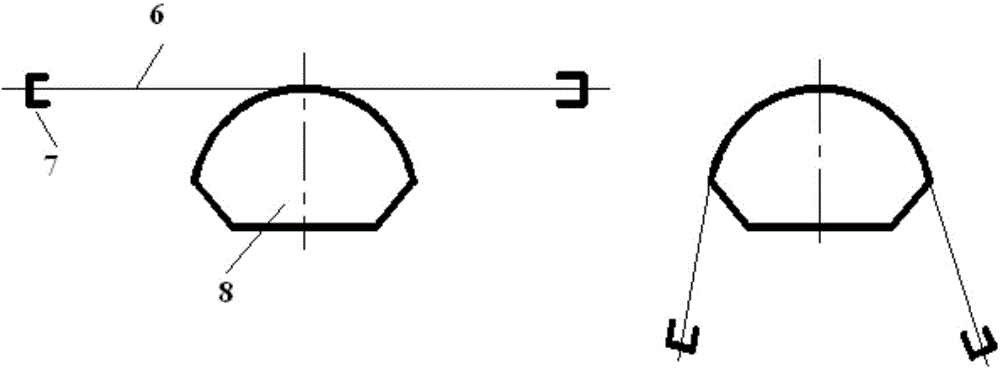

[0048] The bending process is as image 3 shown. Stretch bending is to apply tangential tension while the wool 6 is bent, changing the stress state in the section of the wool 6, reducing or basically eliminating the bending springback, thereby improving the accuracy of the parts. The wool 6 is put into the jaw 7 and pre-stretched, the pre-stretched wool 6 is bent along the stretch bending die 8, and finally the pulling force is added to make it stick the film.

[0049] The stretch-bending forming method of the double-open hollow profile frame of the present invention comprises the following steps:

[0050] Step 1: Forming preparation

[0051] 1.1 Receive the straight profile material (2A12O) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com