Water-based normal-temperature-curable peelable paint for safekeeping and protection of instrument and equipment

A room temperature curing and equipment technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor barrier performance of single-component film-forming materials, poor environmental performance of solvent-based peelable and sealed coatings, etc., to achieve Good peelability, convenient construction and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

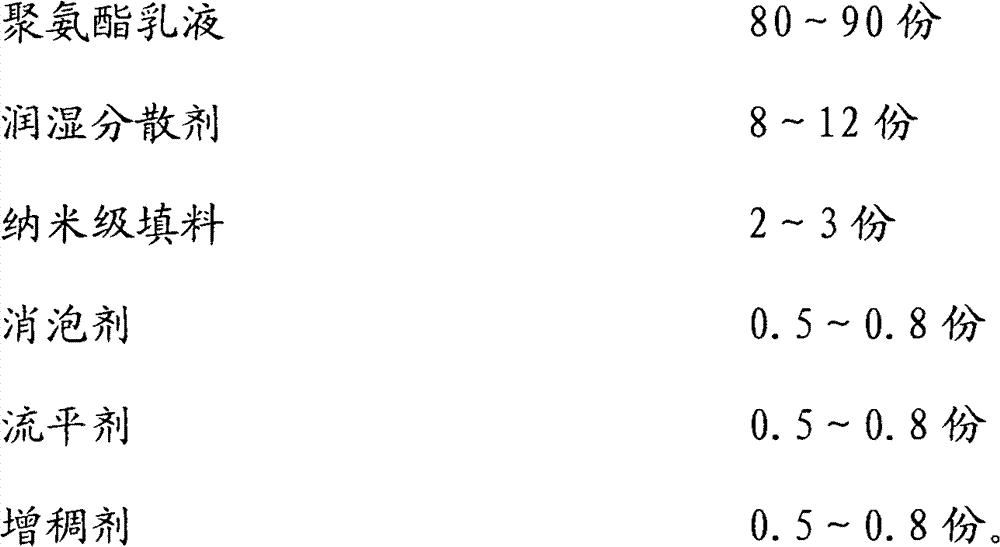

[0025] The water-based room temperature curing peelable coating used for the protection of instruments and equipment is composed of raw materials with the following weight ratio:

[0026]

[0027] Wherein, the wetting and dispersing agent is acrylic acid copolymer sodium salt solution. Polyurethane emulsion is non-ionic containing non-ionic hydrophilic segments or hydrophilic groups in the molecule, with a solid content of 50±1%, a pH value of 7.5±0.5, a particle size of the emulsion not greater than 200nm, and a glass transition temperature range of - 25~-5℃. The nano-scale filler is nano-titanium dioxide with an average particle diameter of 40 nm. The defoamer is a mixture of foam breaking polysiloxane and hydrophobic particles. The leveling agent is polyether modified polydimethylsiloxane copolymer solvent. The thickener is a modified urea polyurethane solution.

[0028] The water-based room temperature curing peelable coating used for the preservation and protection...

Embodiment 2

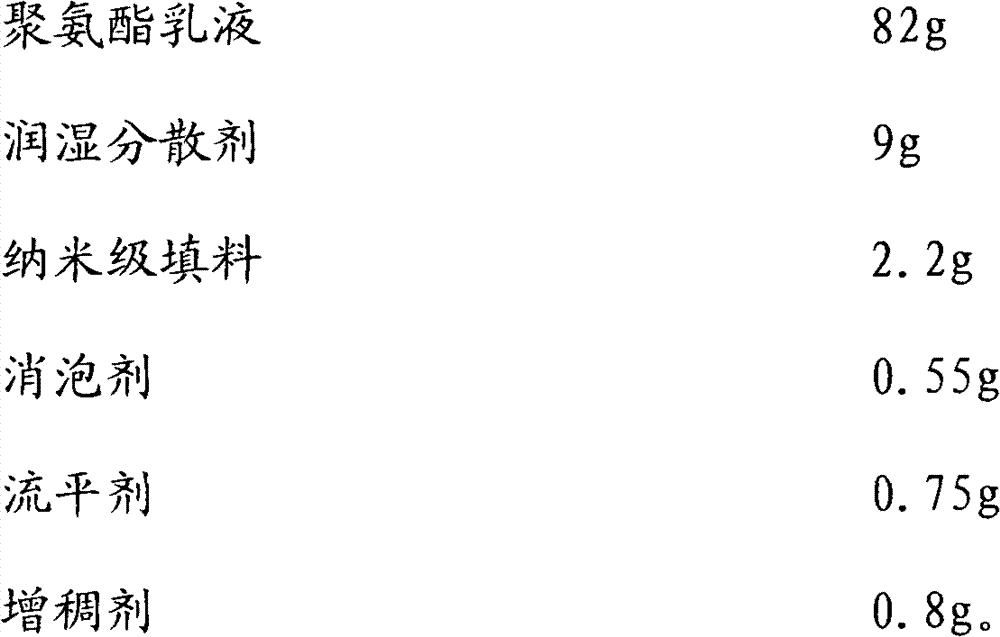

[0031] The water-based room temperature curing peelable coating used for the protection of instruments and equipment is composed of raw materials with the following weight ratio:

[0032]

[0033]

[0034] Wherein, the wetting and dispersing agent, polyurethane emulsion, nano-scale filler, defoamer, leveling agent and thickener are the same as in Example 1.

[0035] The water-based room temperature curing peelable coating used for the preservation and protection of instruments and equipment, the steps are as follows:

[0036] Under the condition of stirring at 1500rpm, add nano-scale fillers to the polyurethane emulsion with wetting and dispersing agent, disperse for 2 hours with a sand mill, disperse, and stir multipurpose machine, then add defoamer, leveling agent and thickener in sequence, and disperse Serve evenly.

Embodiment 3

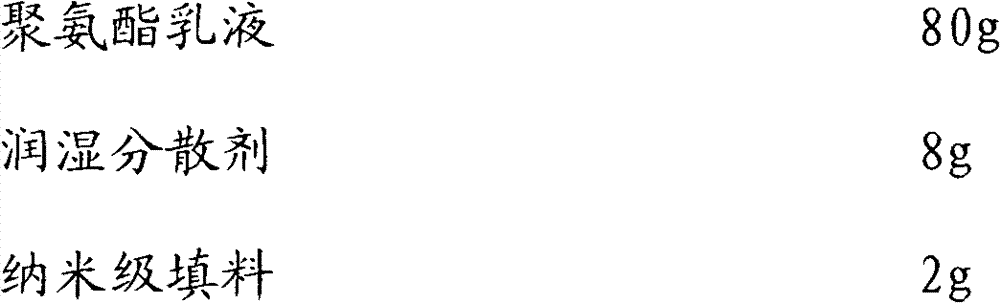

[0038] The water-based room temperature curing peelable coating used for the protection of instruments and equipment is composed of raw materials with the following weight ratio:

[0039]

[0040] Wherein, the wetting and dispersing agent, polyurethane emulsion, nano-scale filler, defoamer, leveling agent and thickener are the same as in Example 1.

[0041] The water-based room temperature curing peelable coating used for the preservation and protection of instruments and equipment, the steps are as follows:

[0042] Under the condition of stirring at 1400rpm, add nano-scale fillers to the polyurethane emulsion with wetting and dispersing agent, disperse with sand milling, dispersing and stirring multipurpose machine for 2.4 hours, and then add defoamer, leveling agent and thickener in sequence, Get it after it is evenly dispersed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com