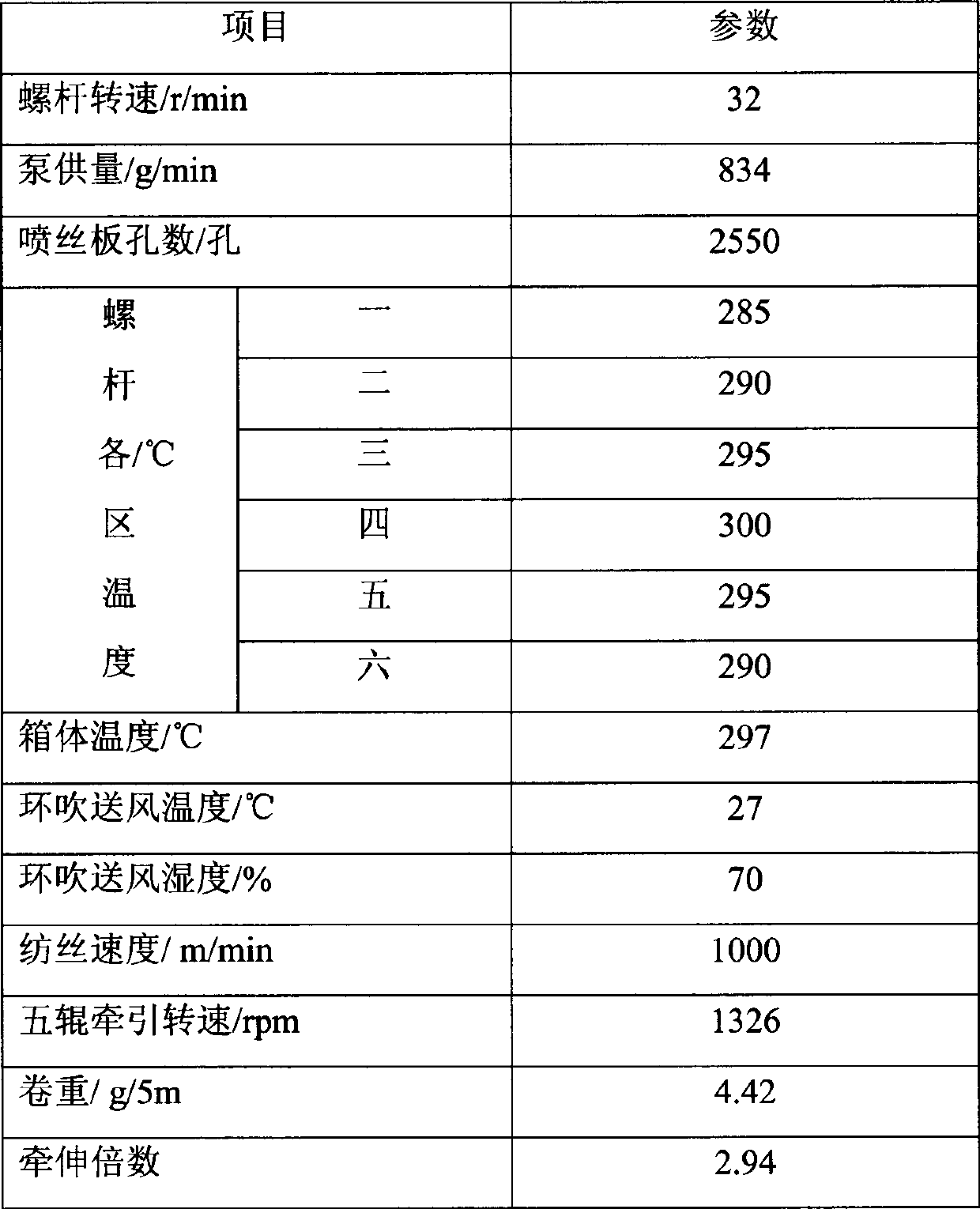

Normal-pressure boiling dyeable biomass polyester fiber and preparation method thereof

A polyester fiber and biomass technology, which is applied in the field of biomass polyester fiber and its preparation, can solve the problems that biomass fiber cannot realize atmospheric pressure boiling dyeing characteristics, cannot be continuously produced, and has high equipment costs, so as to promote sustainable development , cost saving and high dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

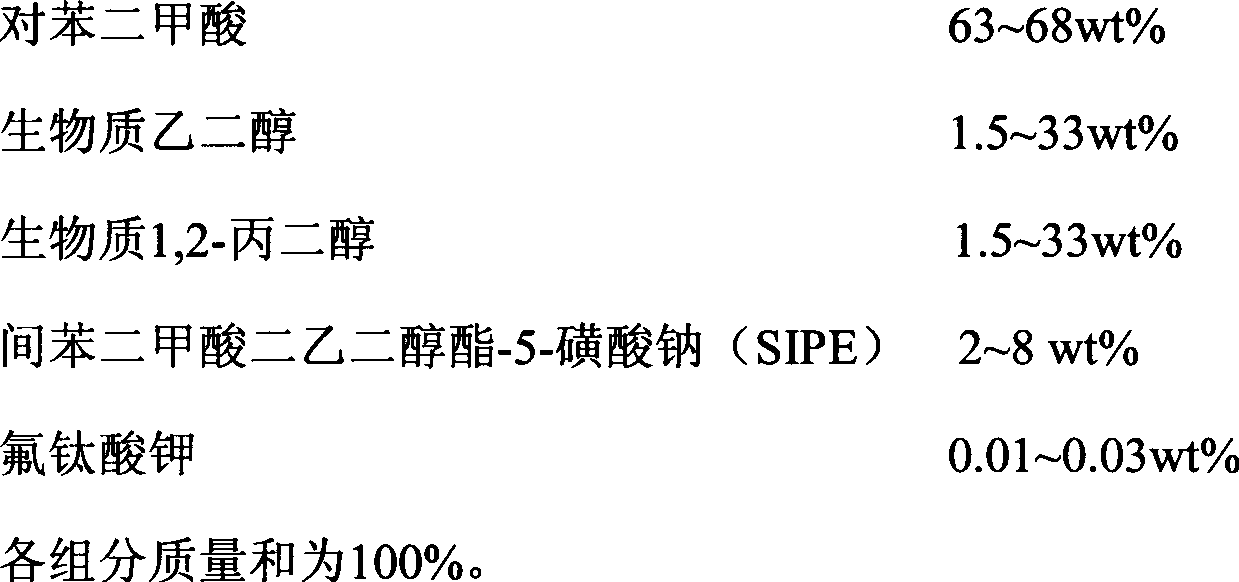

[0023] Configure terephthalic acid 66wt%, biomass ethylene glycol 28.48wt%, biomass 1,2-propanediol 1.5wt%, add to the reaction kettle, heat up and maintain pressure, and carry out esterification reaction at a temperature of 225 ° C and a pressure of 0.4 MPa. After cooling, add diethylene glycol isophthalate-5-sodium sulfonate (SIPE) 4wt% and catalyzer potassium fluotitanate 0.02wt% to carry out temperature rise vacuum polycondensation reaction, make biomass polyester chip, whole reaction is in Completed in batch production plant. The prepared biomass polyester chips are dried, spun on the LHV431 type spinning machine, drawn and spun on the LHV903 combined drawing machine, and dried, spun, wound, formed, bundled, drawn, crimped, The biomass polyester fiber is obtained after cutting, and its main control production process parameters are shown in Table 1.

[0024] The control dyeing test is: the PET fiber prepared in the same spinning and drawing equipment using the convention...

Embodiment 2

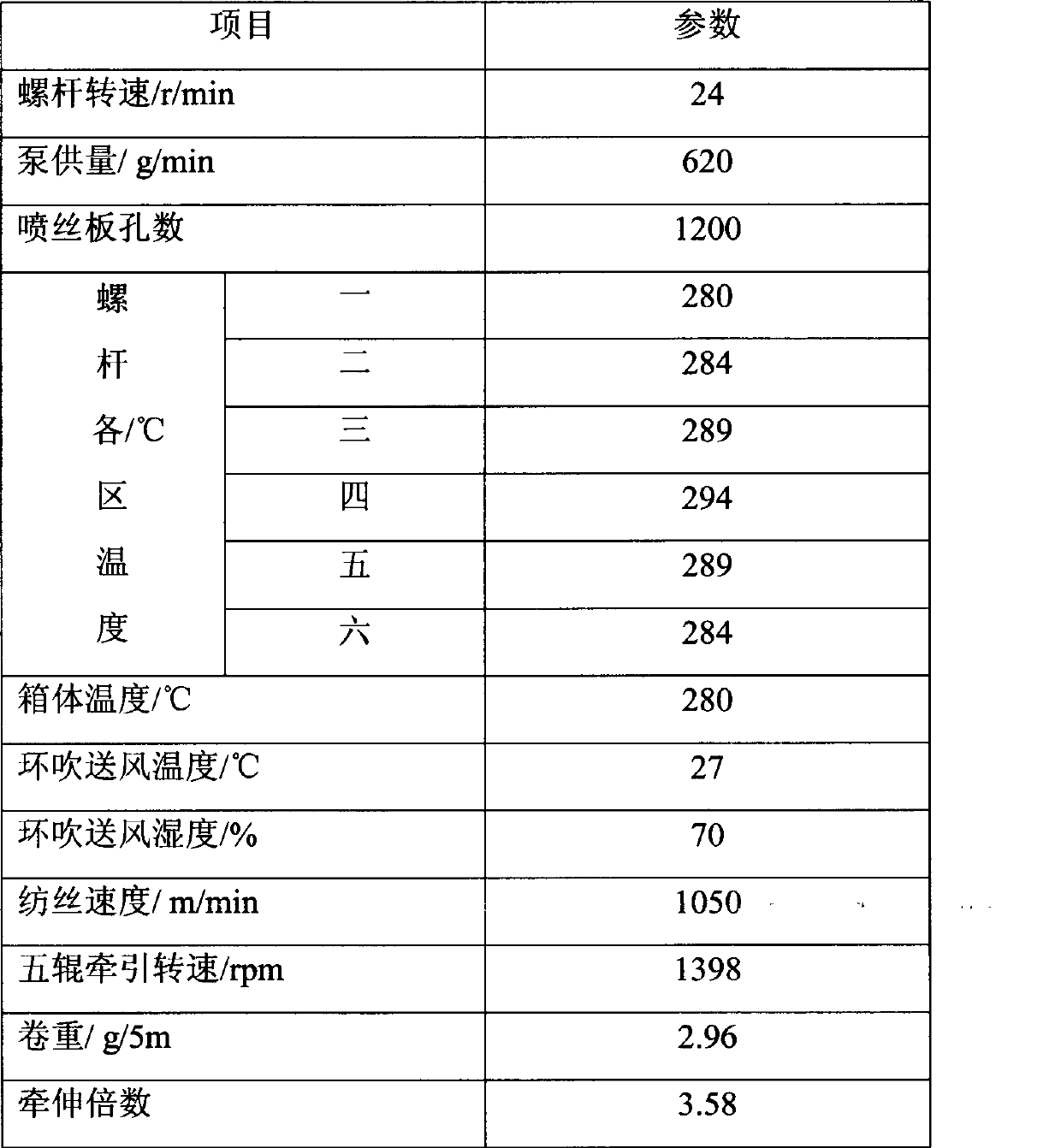

[0029] Configure 64wt% terephthalic acid, 1.5wt% biomass ethylene glycol, and 32.47wt% biomass 1,2-propanediol, add them to the reactor, heat up and maintain pressure, and carry out esterification reaction at a temperature of 220°C and a pressure of 0.6MPa. Add Diethylene Glycol Isophthalate-5-Sodium Sulfonate (SIPE) 2wt% and Catalyst Potassium Fluotitanate 0.03wt% to carry out temperature rise vacuum polycondensation reaction to make biomass polyester chips, the whole reaction is carried out in a batch production device The prepared biomass polyester chips are dried in the process, spun on the LHV431 type spinning machine, drawn and spun on the LHV903 combined drawing machine, and dried, spun, wound, formed, bundled, drawn, The biomass polyester fiber is obtained after crimping and cutting, and its main control production process parameters are shown in Table 2.

[0030] Table 2 A kind of production process parameter of atmospheric pressure boiling dyeing biomass polyester fi...

Embodiment 3

[0035] Configure terephthalic acid 65wt%, biomass ethylene glycol 26.4wt%, biomass 1,2-propanediol 5.58wt%, add to the reaction kettle, heat up and maintain pressure, and carry out esterification reaction at a temperature of 230 ° C and a pressure of 0.6 MPa. Add diethylene glycol isophthalate-5-sodium sulfonate (SIPE) 3wt% and catalyst potassium fluorotitanate 0.02wt% to carry out temperature-raising vacuum polycondensation reaction to obtain biomass polyester chips, and the whole reaction is carried out in a batch production device The prepared biomass polyester chips are dried in the process, spun on the LHV431 type spinning machine, drawn and spun on the LHV903 combined drawing machine, and dried, spun, wound, formed, bundled, drawn, The biomass polyester fiber is obtained after crimping and cutting, and its main control production process parameters are shown in Table 3.

[0036] The control dyeing test is: using the conventional production process, PET fibers prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com