Zero-dimensional and one-dimensional calcium carbonate micro-nano composite product taking cement and 'three wastes' as raw materials, composite material and synthesis process

A composite, micro-nano technology, which is applied in the field of raw material storage of micro-nano new materials, can solve the problems such as the workability and strength improvement of concrete mortar, and achieve the advantages of cheap raw materials, wide application range and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

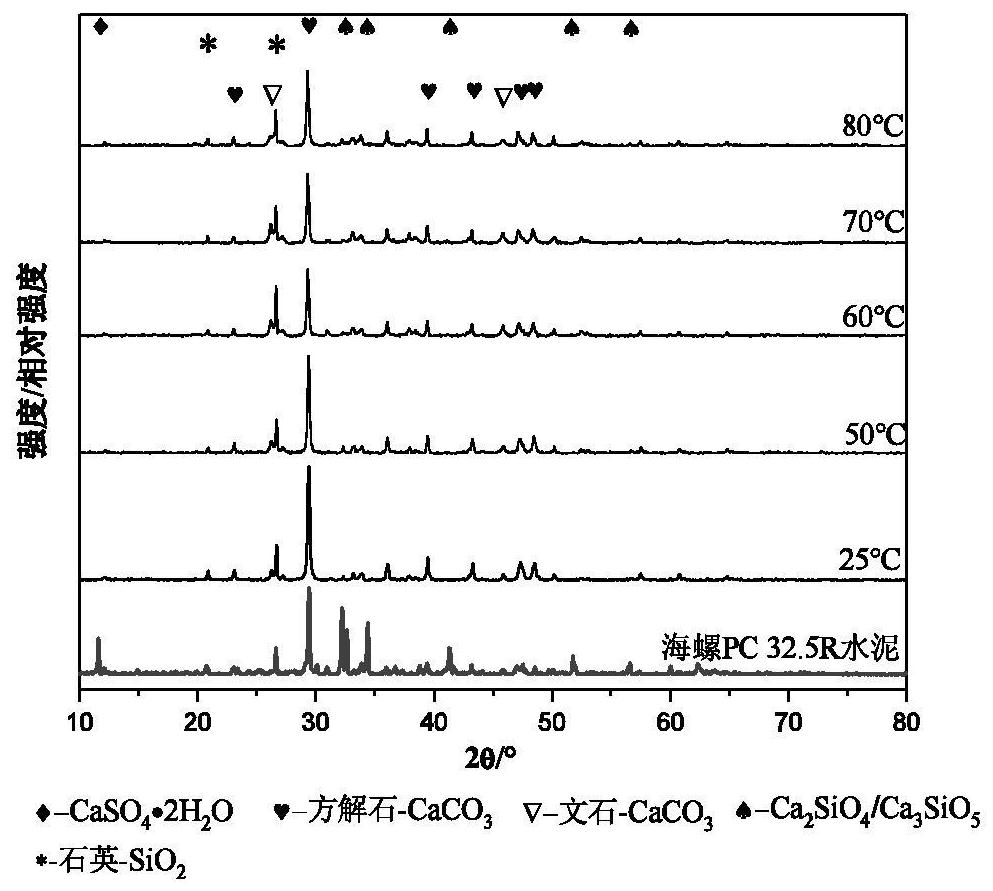

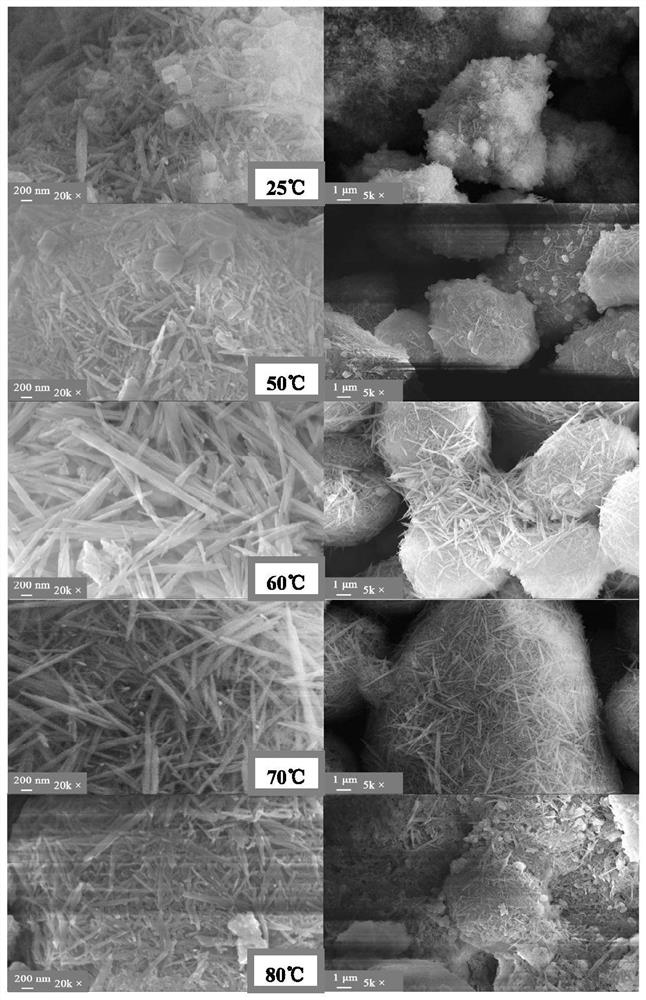

[0102] Example 1: Using Portland cement and carbon dioxide as raw materials, carbonization at different temperatures prepares micro-nano composite products

[0103] Add 100g of PC32.5R portland cement to 200g of water, and the system is at room temperature (25°C), 50°C, 60°C, 70°C, and 80°C, and mechanically stirred evenly, and carbon dioxide gas is introduced at a flow rate of 0.5L / min , respectively reacted for 4 hours, filtered with suction, washed with ethanol, and dried at 180°C for 1 hour to obtain the product.

[0104] The whole hole analysis result of raw material and material in table 1 embodiment 1

[0105]

[0106] figure 1 , figure 2 , table 1 is the follow-up figure and the whole hole analysis result of XRD and SEM of preparing aragonite type calcium carbonate composite product under different temperatures in embodiment 1, the result shows that when solid-liquid ratio is 1 / 2, at different temperatures all The formation of aragonite structure shows that hig...

Embodiment 2

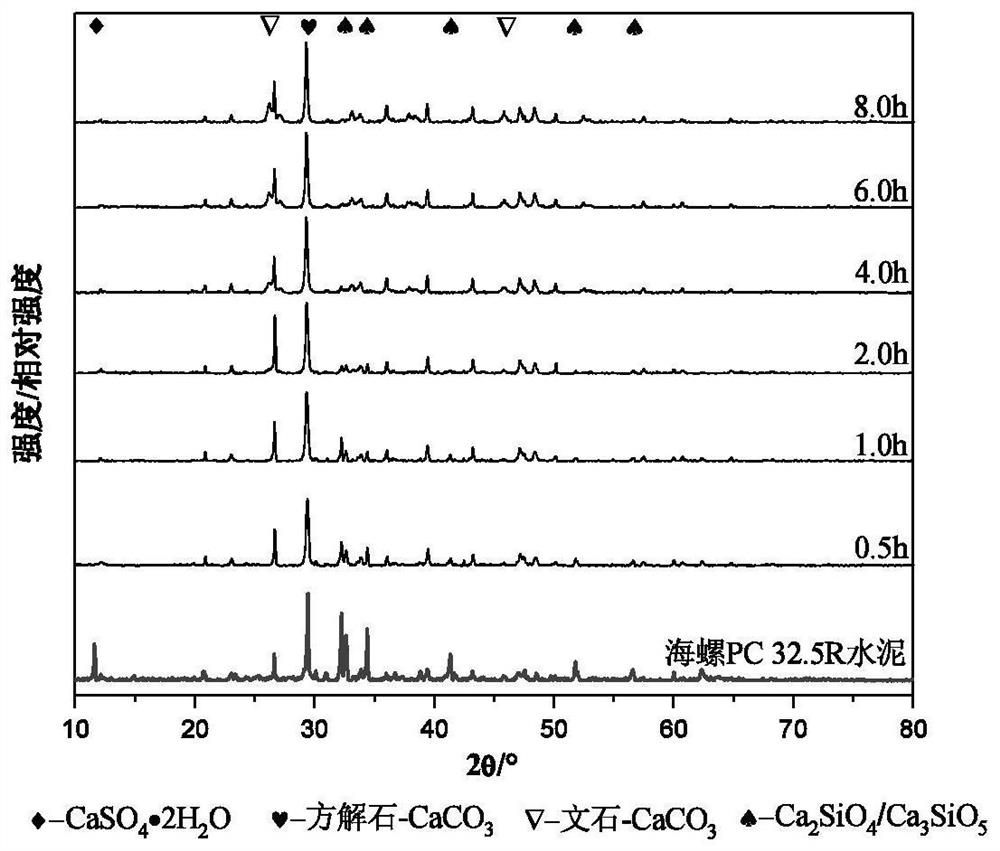

[0107] Example 2: Using Portland cement and carbon dioxide as raw materials, micro-nano composite products synthesized at different reaction times

[0108] Add 100g of PC32.5R Portland cement to 200g of water, raise the temperature of the system to 80°C, stir it evenly, feed carbon dioxide gas at a flow rate of 0.5L / min, and react for 0.5h, 1h, 2h, 4h, 6h, 8h respectively After that, it was suction filtered, washed with water, and dried at 180°C for 1 hour to obtain the product.

[0109] The whole hole analysis result of raw material and different time complex products in the embodiment of table 2

[0110]

[0111] image 3 , Pic 4-1 , Figure 4-2 , Table 2 is the XRD and SEM tracking situation and the whole hole analysis result of the aragonite calcium carbonate composite product prepared in different reaction times of embodiment 2. According to XRD and SEM analysis, it can be seen that in the first 0.5h, the gas is adsorbed on the surface of the cement and reacts to ...

Embodiment 3

[0112] Example 3: Using Portland cement and carbon dioxide as raw materials to prepare micro-nano composite products with different solid-to-liquid ratios

[0113] Add 100g of PC32.5R Portland cement to 100g, 200g, 300g, 400g, 500g of water respectively, raise the temperature of the system to 70°C, stir it evenly, and introduce carbon dioxide gas at a flow rate of 0.5L / min. Filter, wash with water, and dry at 180° C. for 1 hour to obtain 119 g, 129 g, 128 g, 128 g, and 130 g of products.

[0114] Figure 5 , Image 6 The XRD figure and the SEM figure of the aragonite type calcium carbonate composite product prepared for different solid-to-liquid ratios of embodiment 3. The results showed that no aragonite structure was formed when the solid-liquid ratio was 1:1 or 1:5 at 70°C, which indicated that the formation of aragonite structure required a moderate solid-liquid ratio in the system. Combined with the observation of the reaction process, it was found that the formation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com