Acetylene gas purification device and process thereof

A purification device, acetylene gas technology, applied in inorganic chemistry, sulfur compounds, organic chemistry, etc., can solve the problems of high treatment cost, large amount of waste water, high chloride content in calcium carbide slag, and achieve the effect of strong fault adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

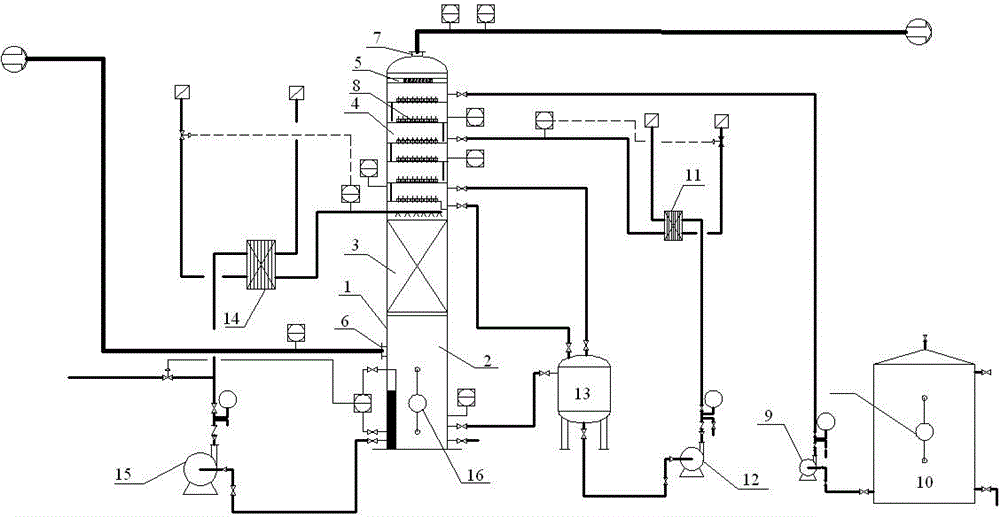

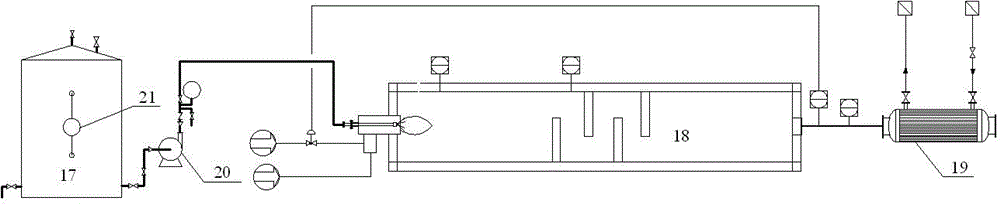

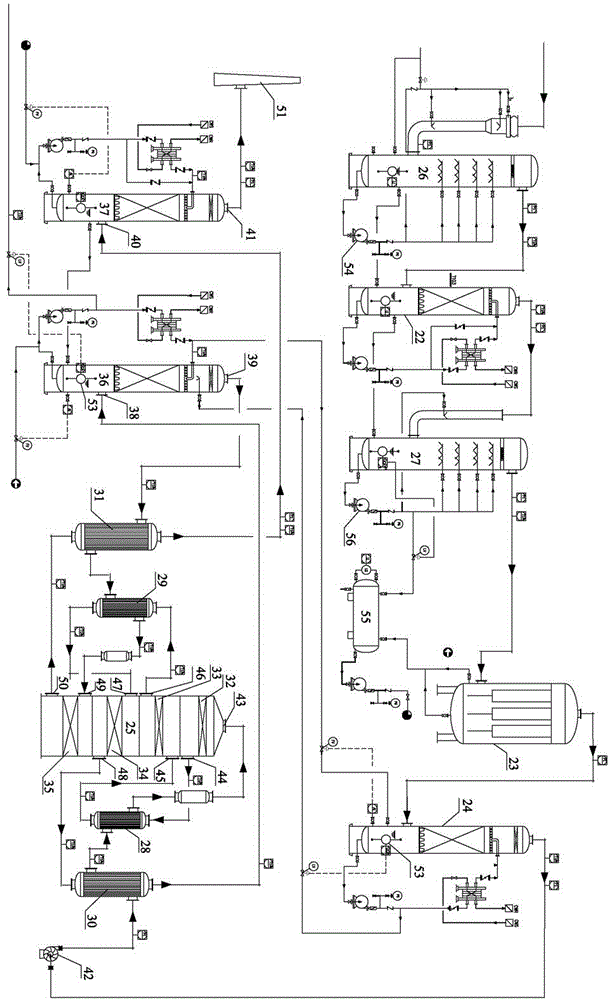

[0053] refer to Figure 1~4 , an acetylene gas purification device, including concentrated sulfuric acid acetylene purification system, waste sulfuric acid pyrolysis purification system and flue gas purification acid production system,

[0054] The concentrated sulfuric acid acetylene purification system includes a purification tower 1, which is sequentially provided with an acid storage section 2, a packing section 3, a bubble cap section 4 and a demister section 5 from bottom to top in the purification tower 1, and the lower part of the purification tower An air inlet 6 is provided, and an air outlet 7 is provided on the top of the purification tower. The packing section 3 is located above the air inlet 6, and the defogging section 5 is located below the air outlet 7. The purif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com