Aluminum or aluminum alloy protection chromium-free passivation solution, preparation method and aluminum or aluminum alloy surface protection method thereof

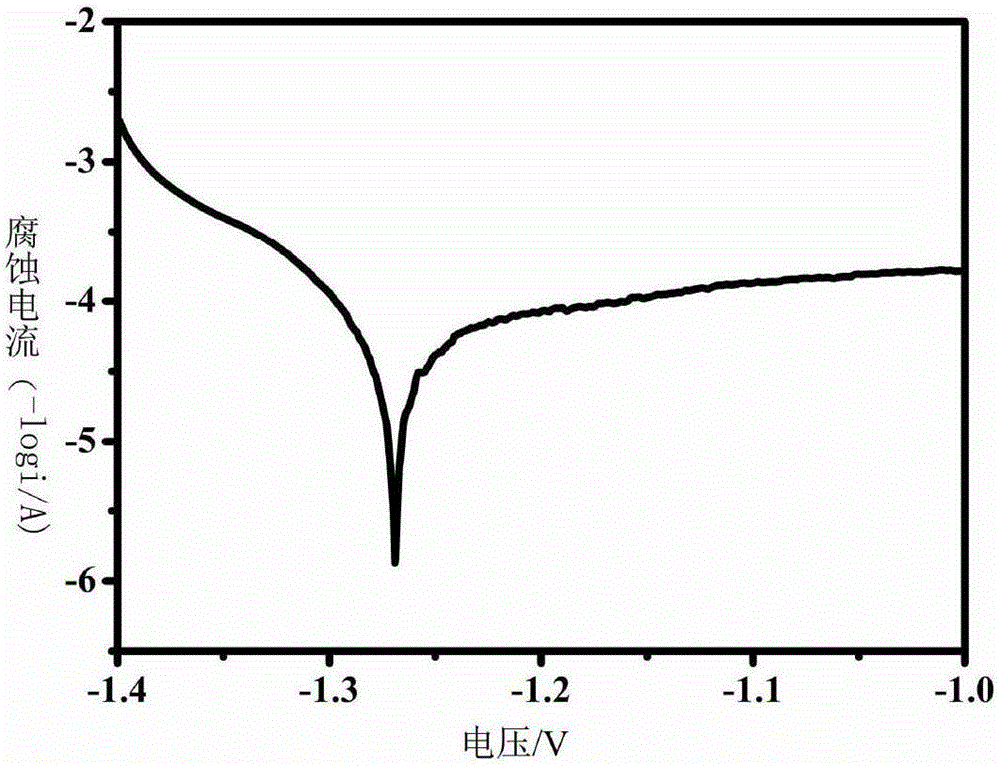

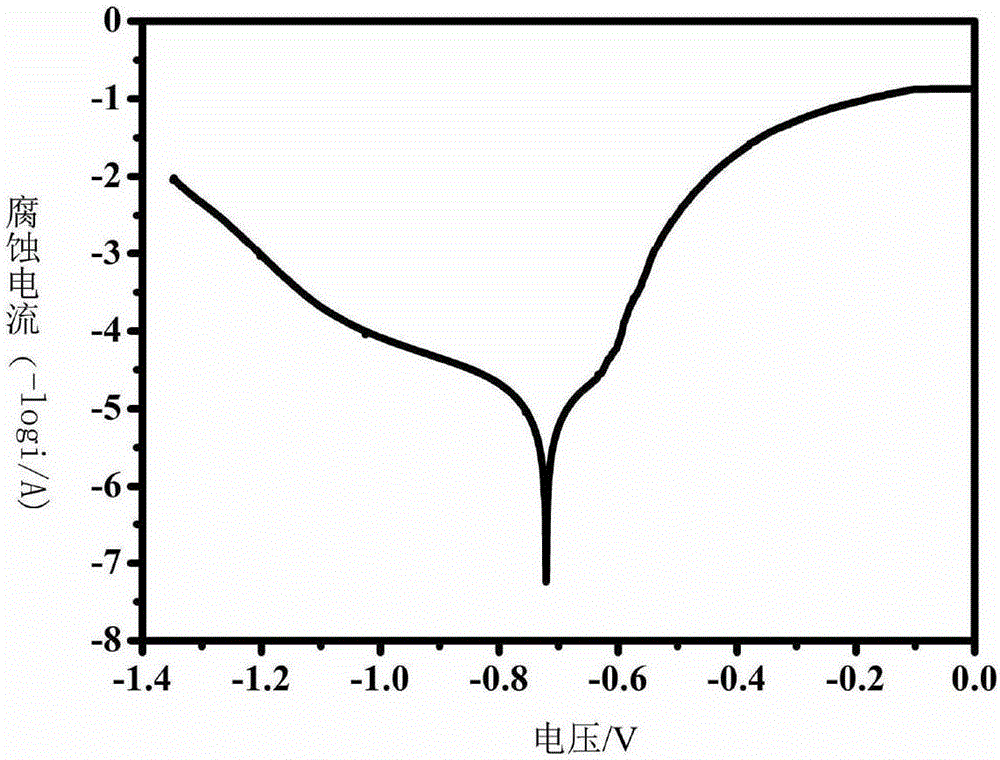

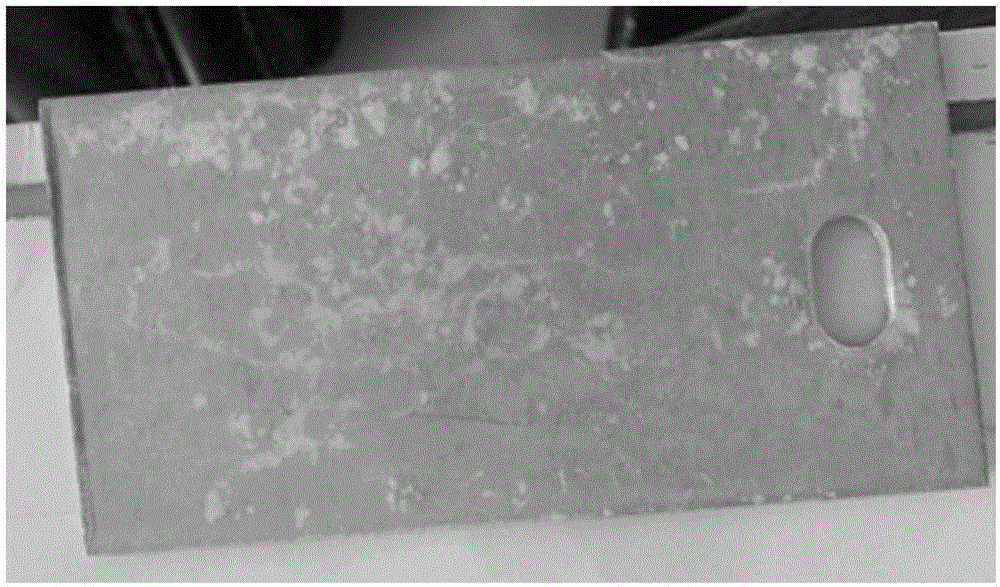

A chromium-free passivation technology for the surface of aluminum alloys, applied in the coating process of metal materials, etc., can solve problems such as weak adhesion, decreased anti-corrosion ability, human body and environmental hazards, etc., and achieve the effect of dense and uniform corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Technical scheme of the present invention is as follows:

[0012] A chromium-free passivation solution for aluminum or aluminum alloy protection. The chromium-free passivation solution is prepared by using a silane coupling agent as a silicon source, an inorganic salt solution of rare earth ions as a hydrolysis accelerator, and adding an organic corrosion inhibitor. ;

[0013] The rare earth ions are lanthanum, yttrium, cerium and / or molybdenum.

[0014] The preparation method of above-mentioned aluminum or aluminum alloy protective chromium-free passivation solution, comprises steps as follows:

[0015] (1) Add the silane coupling agent to methanol aqueous solution or ethanol aqueous solution, stir evenly to obtain solution A; the volume ratio of silane coupling agent: methanol aqueous solution or ethanol aqueous solution is (5-20): (20-40);

[0016] (2) Add the inorganic salt of the rare earth ion and the corrosion inhibitor into the water and stir evenly to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| corrosion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com