Treatment liquid and treatment method for preparing zirconium-based colored conversion film on magnesium alloy surface

A treatment method, magnesium alloy technology, applied in the direction of metal material coating process, etc., can solve the problems of long film forming time, colorless film layer, inconvenient on-site observation and judgment, etc., achieve good gloss, smooth surface, easy to observe and The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

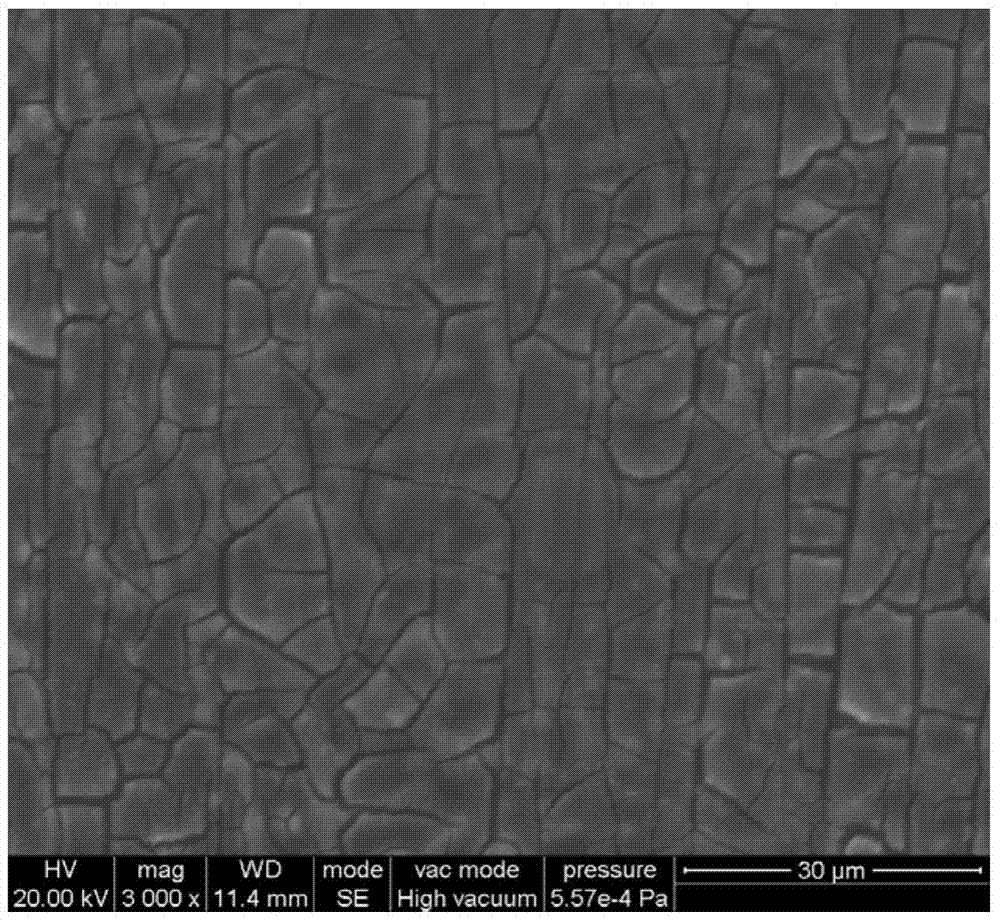

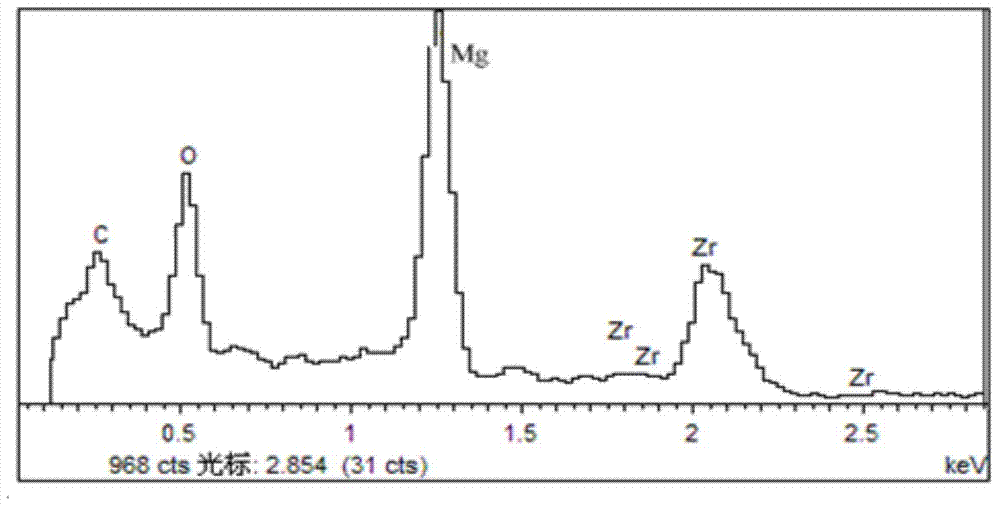

[0071] In this embodiment, the AZ91D magnesium alloy material is used as the substrate, and the treatment method for preparing a zirconium-based colored conversion film on the surface of the magnesium alloy includes the following steps:

[0072] (1) Pre-treatment the surface of the magnesium alloy: grind the magnesium alloy to 1200# with SiC sandpaper, and then carry out the above-mentioned alkaline solution degreasing treatment: soak the magnesium alloy in an alkaline solution at 25°C for 30 minutes, and each liter of alkali The neutral solution contains 50g sodium hydroxide, 20g anhydrous sodium carbonate and 40g sodium silicate.

[0073] (2) Place the magnesium alloy treated in step (1) in the treatment solution, and soak it at 35°C for 3 minutes to prepare a colored zirconium-based conversion film on the surface of the magnesium alloy;

[0074] The composition of the treatment solution is as follows: every liter of the treatment solution contains 1.5g of zirconium-containi...

Embodiment 2

[0080] In this embodiment, the AZ91D magnesium alloy material is used as the substrate, and the treatment method for preparing a zirconium-based colored conversion film on the surface of the magnesium alloy includes the following steps:

[0081] (1) Pre-treatment the surface of the magnesium alloy: grind the magnesium alloy to 1200# with SiC sandpaper, and then carry out the degreasing treatment of the above-mentioned alkaline solution: soak the magnesium alloy in the alkaline solution at 35°C for 10 minutes, each liter of alkali The neutral solution contains 80g sodium hydroxide, 10g anhydrous sodium carbonate and 20g sodium silicate.

[0082] (2) Place the magnesium alloy treated in step (1) in the treatment solution, and soak it at 35°C for 5 minutes to prepare a colored zirconium-based conversion film on the surface of the magnesium alloy;

[0083] The composition of the treatment solution is as follows: every liter of the treatment solution contains 1.5g of zirconium-cont...

Embodiment 3

[0086] In this embodiment, the AZ91D magnesium alloy material is used as the substrate, and the treatment method for preparing a zirconium-based colored conversion film on the surface of the magnesium alloy includes the following steps:

[0087] (1) Pre-treatment the surface of the magnesium alloy: grind the magnesium alloy to 1200# with SiC sandpaper, and then carry out the above-mentioned alkaline solution degreasing treatment: soak the magnesium alloy in an alkaline solution at 30°C for 20 minutes, and each liter of alkali The neutral solution contains 20g sodium hydroxide, 30g anhydrous sodium carbonate and 60g sodium silicate.

[0088] (2) Place the magnesium alloy treated in step (1) in the treatment solution, and soak it at 30°C for 1 min to prepare a colored zirconium-based conversion film on the surface of the magnesium alloy;

[0089] The composition of the treatment solution is as follows: every liter of the treatment solution contains 0.5g of zirconium-containing m...

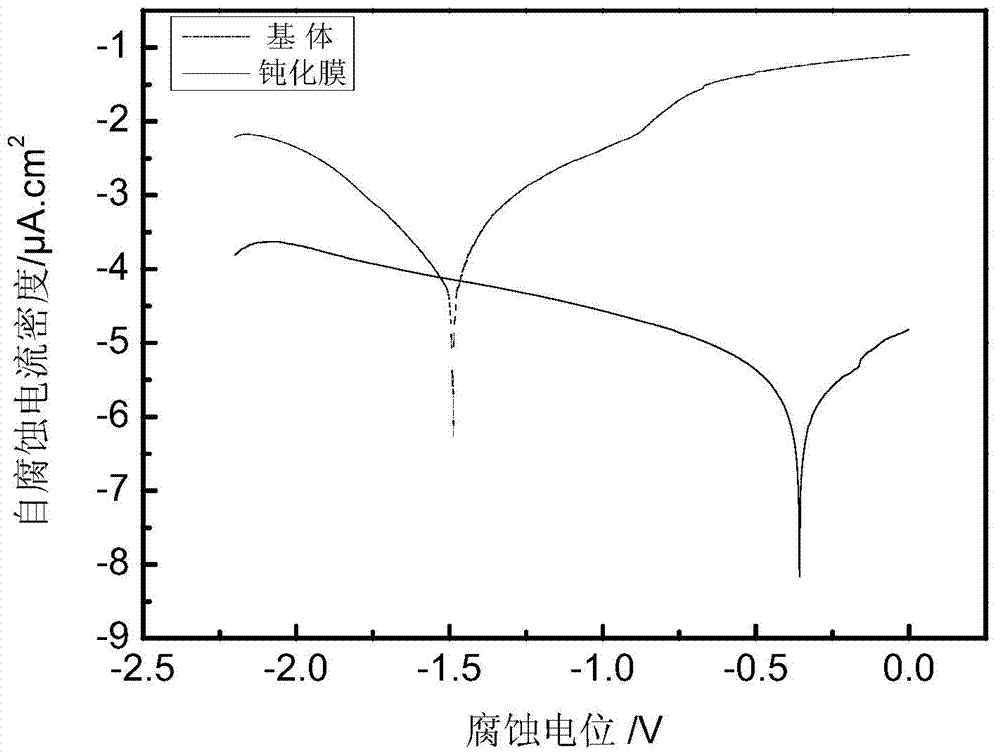

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com