Electroluminescence device and manufacturing method thereof

An electroluminescence device and photoresist technology, which is applied to circuits, electrical components, electrical solid devices and other directions, can solve the problems of difficulty in etching the connecting electrode 14 and take a long time, so as to reduce the difficulty of etching, improve the yield, The effect of shortening the film formation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

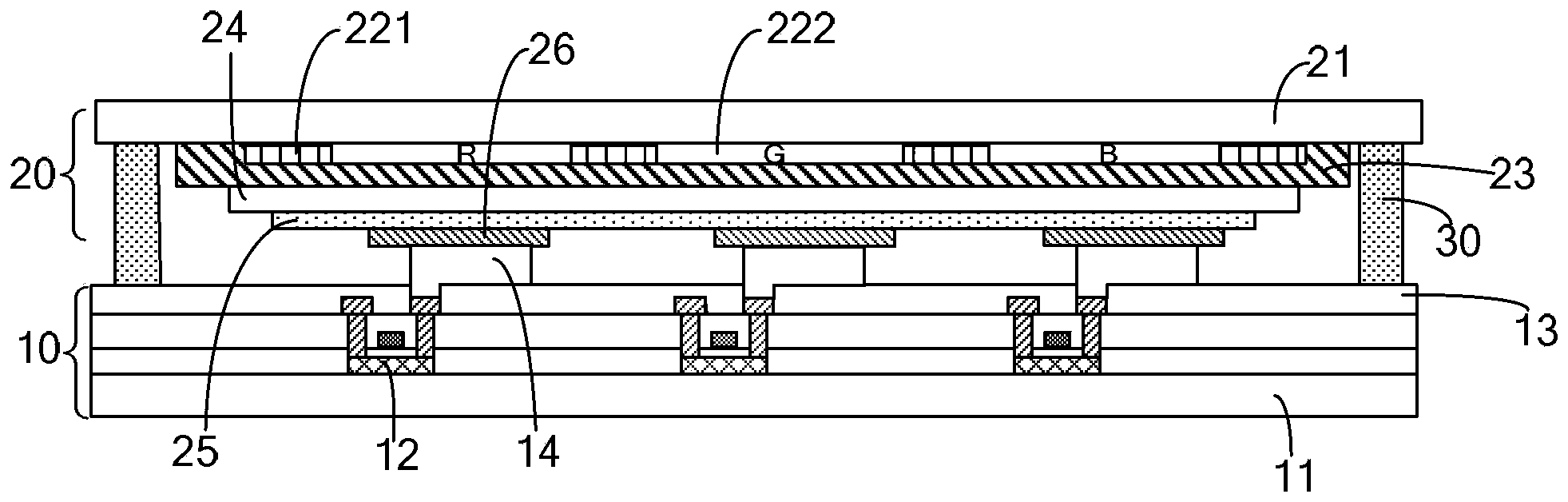

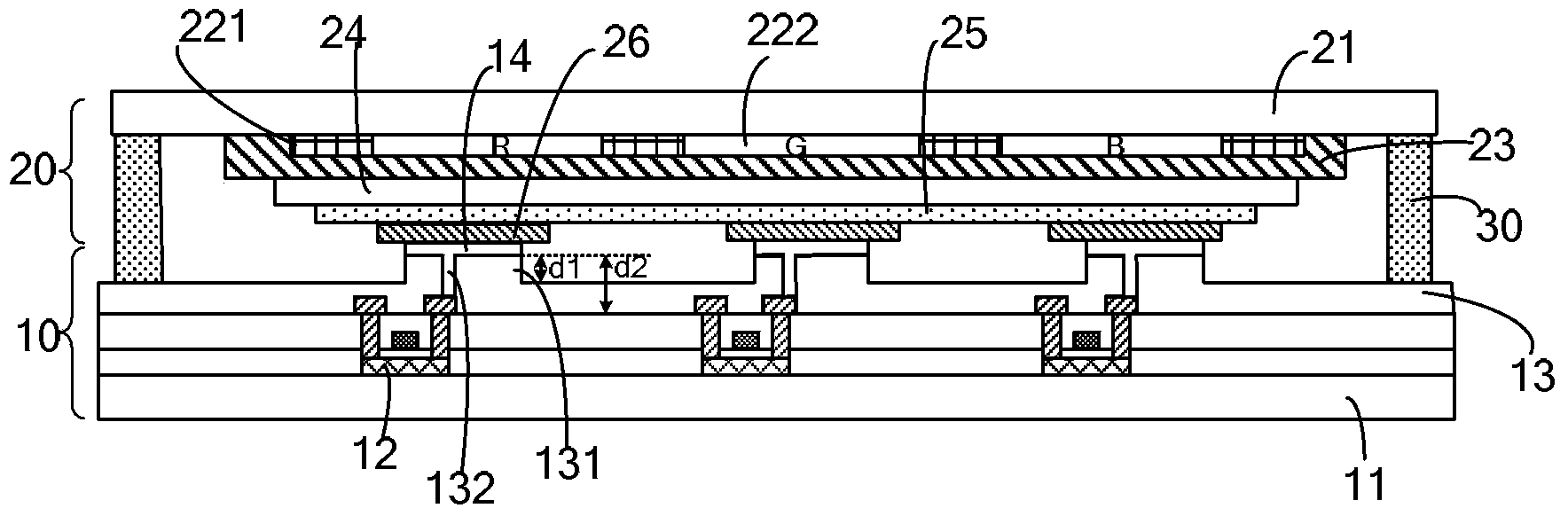

[0061] An embodiment of the present invention provides an electroluminescence device, as shown in FIG. 2(a) and FIG. 2(b), the device includes: an array substrate 10; the array substrate 10 includes: a substrate 11, and the The thin film transistor 12, the protective layer 13 covering the thin film transistor 12, and the connection electrode 14 arranged on the protective layer 13; the protective layer 13 below the connection electrode 14 protrudes to the side away from the substrate 11, forming a boss 131 ; the protective layer 13 is provided with a protective layer via hole 132 at a position corresponding to the drain of the thin film transistor 12 , and the connection electrode 14 is connected to the drain of the thin film transistor 12 through the protective layer via hole 132 .

[0062] A TFT circuit (driver circuit) is provided on the array substrate 10 for driving and compensating the OELD. There are many ways to implement the driving circuit, but the driving circuit at ...

Embodiment 2

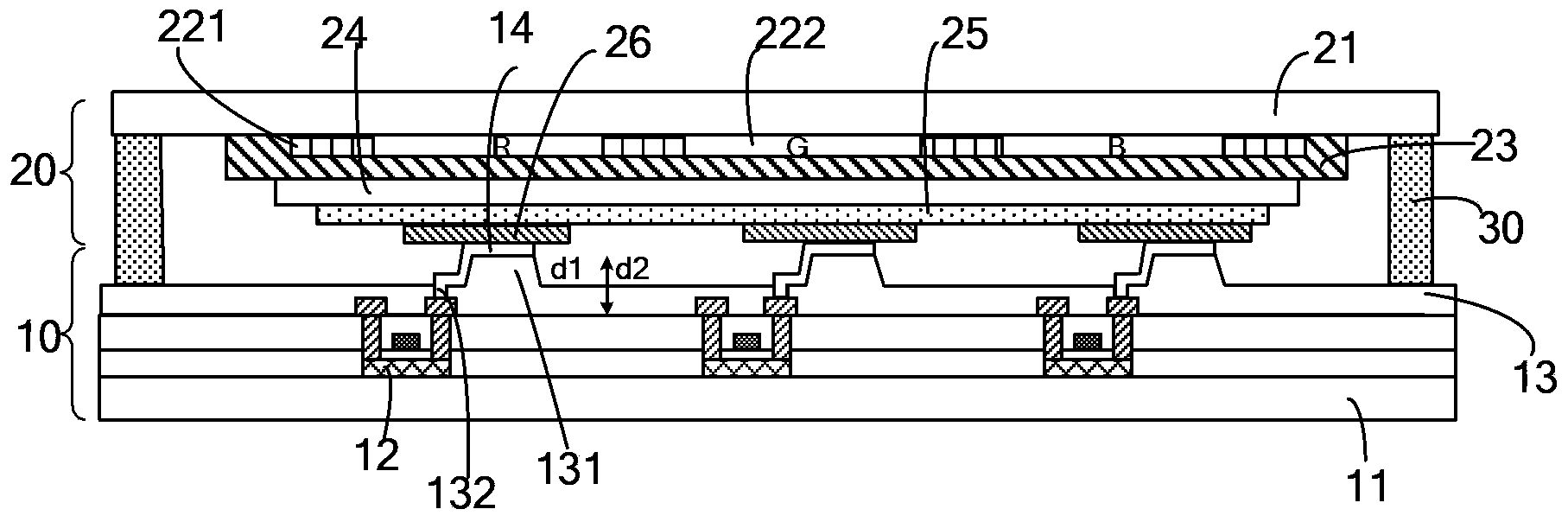

[0073] The embodiment of the present invention also provides a method for manufacturing an electroluminescence device, the preparation method includes: a color filter substrate manufacturing process, an array substrate manufacturing process, a color filter substrate and an array substrate manufacturing process, wherein, such as image 3 As shown, the array substrate manufacturing process includes:

[0074] Step 101, forming a thin film transistor 12 on the substrate 11;

[0075] Step 102: Form a protective layer 13 on the substrate on which the thin film transistor 12 is formed, and form a boss 131 at a predetermined position where the connection electrode is subsequently formed through a patterning process, and form a protective layer via hole 132 at a position corresponding to the drain of the thin film transistor 12 ;

[0076] Step 103 , forming a connection electrode 14 on the protection layer 13 , and connecting the connection electrode 14 to the drain of the thin film t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com