Method for depositing indium sulfide thin film by chemical bath

A chemical bath deposition, indium sulfide technology, applied in chemical instruments and methods, inorganic chemistry, liquid chemical plating and other directions, can solve the problems of substrate selection limitation, destroying the original morphology of the film, affecting the light transmission characteristics of the film, etc. Achieve the effect of shortening film formation time, avoiding homogeneous nucleation and precipitation, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

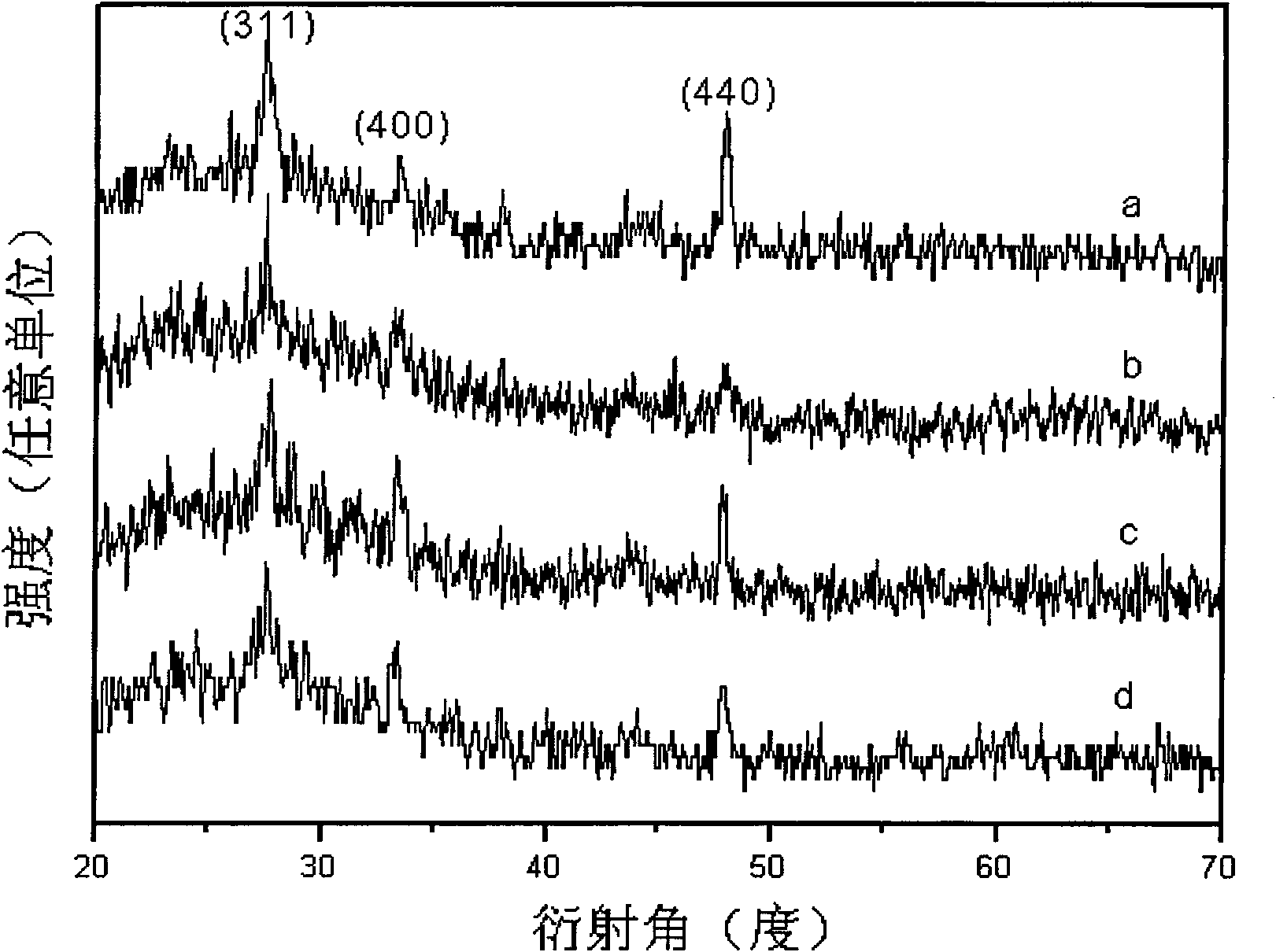

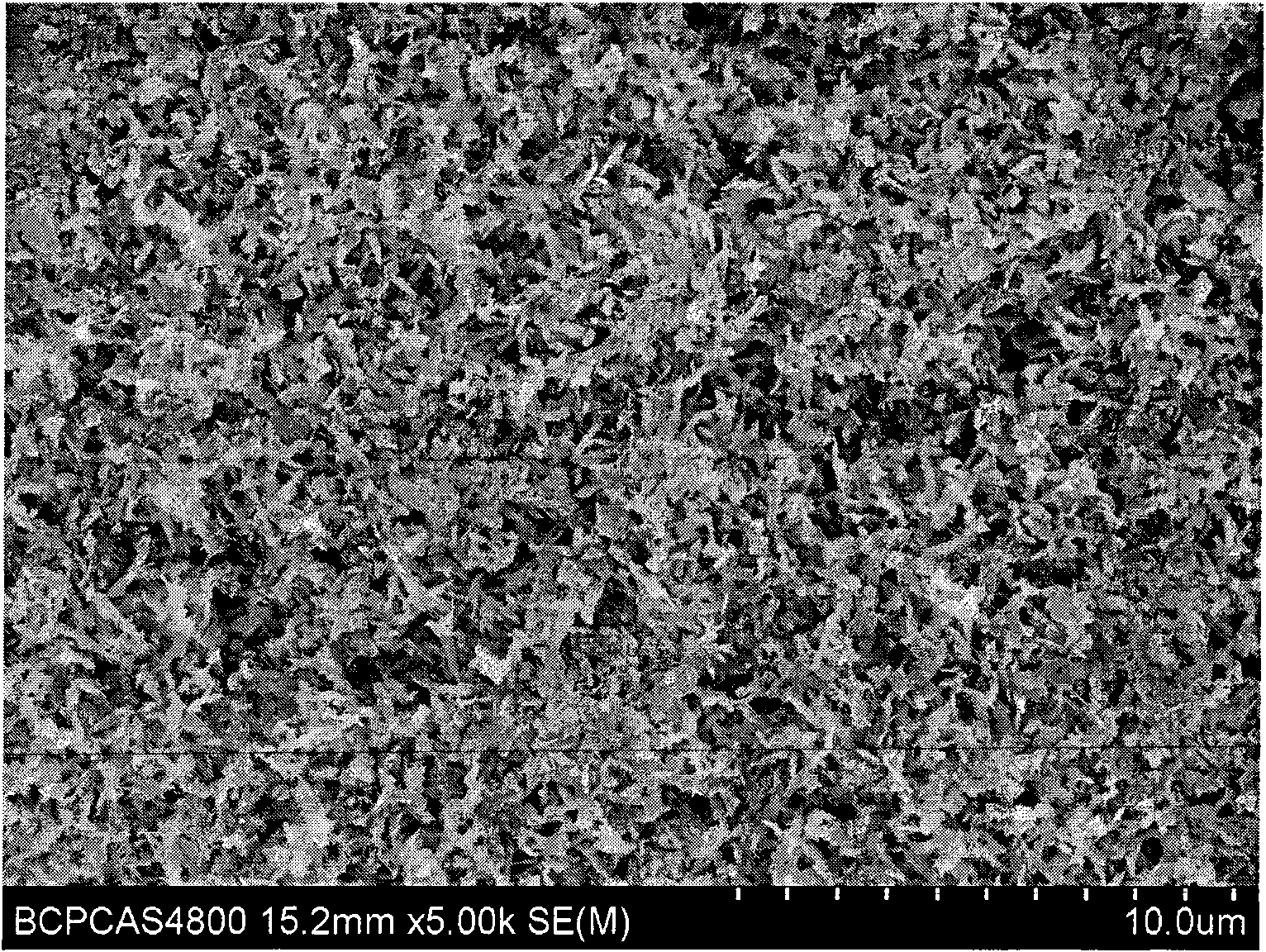

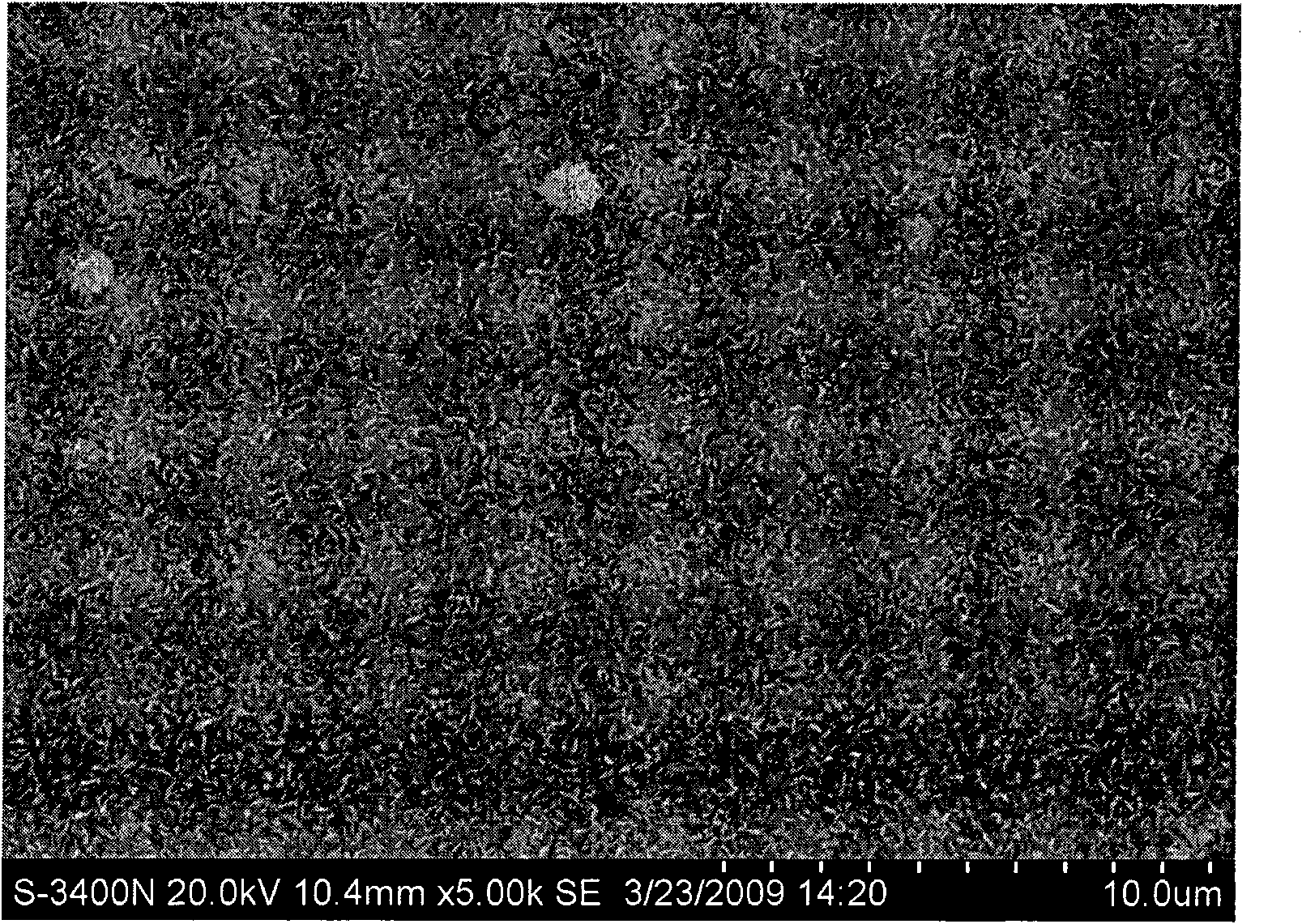

Examples

Embodiment 1

[0028] a) Pretreatment of the substrate: After the ordinary glass substrate is fully cleaned in an ultrasonic cleaner with toluene, acetone, and ethanol in sequence, it is rinsed with deionized water, and then washed with concentrated H with a volume ratio of 7:3. 2 SO 4 and 30%H 2 o 2 The solution was reacted and oxidized at 80°C for 30 minutes, and then the substrate was soaked in an absolute ethanol solution of mercaptosilyl ethyl ester at a volume ratio of 1:100 (mercaptosilyl ethyl ester: absolute ethanol = 1:100) for later use;

[0029] b) Add 0.02mol citric acid into a 100ml beaker, stir with 20ml deionized water to dissolve. After complete dissolution, add 0.003mol InCl 3 4H 2 O, continued stirring to obtain a clear solution A.

[0030] c) Add 1 mol / L HCl solution to solution A, adjust the pH value to 1, and obtain solution B.

[0031] d) Add 0.02mol thioacetamide and 20ml deionized water into a 50ml beaker, dissolve, slowly add the prepared thioacetamide solutio...

Embodiment 2

[0035] a) Pretreatment of the substrate: After the ordinary glass substrate is fully cleaned in an ultrasonic cleaner with toluene, acetone, and ethanol in sequence, it is rinsed with deionized water, and then washed with concentrated H with a volume ratio of 7:3. 2 SO 4 and 30%H 2 o 2 The solution was reacted and oxidized at 80°C for 30 minutes, and then the substrate was soaked in an absolute ethanol solution of mercaptosilyl ethyl ester at a volume ratio of 1:100 (mercaptosilyl ethyl ester: absolute ethanol = 1:100) for later use;

[0036] b) Add 0.02mol citric acid into a 100ml beaker, stir with 20ml deionized water to dissolve. After complete dissolution, add 0.003mol InCl 3 4H 2 O, continued stirring to obtain a clear solution A.

[0037] c) Add 1 mol / L HCl solution to solution A, adjust the pH value to 2, and obtain solution B.

[0038] d) Add 0.02mol thioacetamide and 20ml deionized water into a 50ml beaker, dissolve, slowly add the prepared thioacetamide solutio...

Embodiment 3

[0042] a) Pretreatment of the substrate: After the ordinary glass substrate is fully cleaned in an ultrasonic cleaner with toluene, acetone, and ethanol in sequence, it is rinsed with deionized water, and then washed with concentrated H with a volume ratio of 7:3. 2 SO 4 and 30%H 2 o 2 The solution was reacted and oxidized at 80°C for 30 minutes, and then the substrate was soaked in an absolute ethanol solution of mercaptosilyl ethyl ester at a volume ratio of 1:100 (mercaptosilyl ethyl ester: absolute ethanol = 1:100) for later use;

[0043] b) Add 0.02mol citric acid into a 100ml beaker, stir with 20ml deionized water to dissolve. After complete dissolution, add 0.003mol InCl 3 4H 2 O, continued stirring to obtain a clear solution A.

[0044] c) Add 1 mol / L HCl solution to solution A, adjust the pH value to 2, and obtain solution B.

[0045] d) Add 0.02mol thioacetamide and 20ml deionized water into a 50ml beaker, dissolve, slowly add the prepared thioacetamide solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com