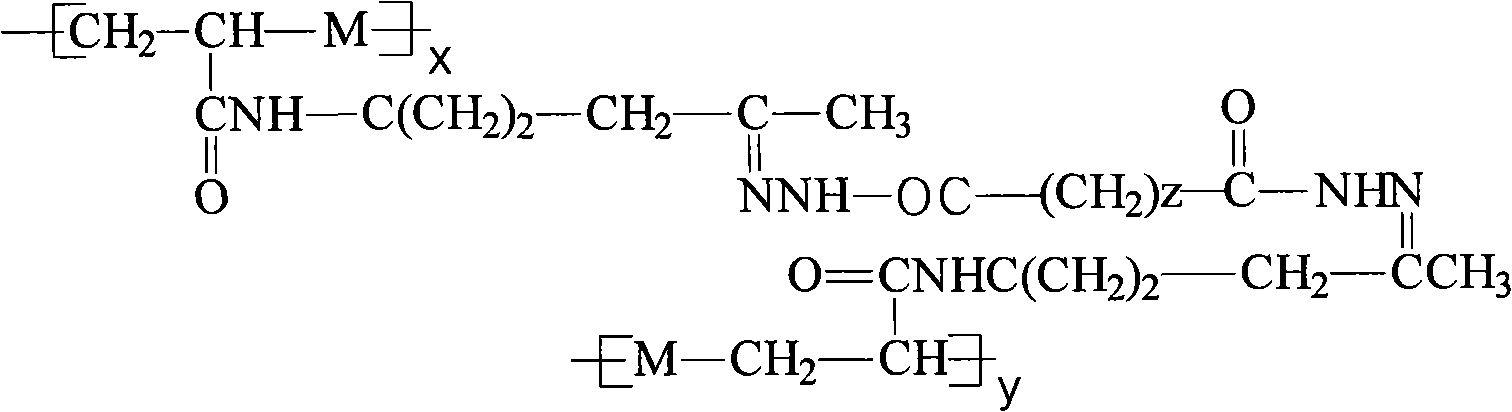

Film-forming agent for seed clothing sheet and preparation method thereof

A film-forming agent and coating technology, applied in the field of film-forming agent for seed coating and its preparation, can solve the problems of poor film wear resistance, low seed germination rate, poor slow-release control ability, etc. High uniformity, high coating coverage, and the effect of promoting crop growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1. Preparation of film-forming agent for seed coating and verification of its effect

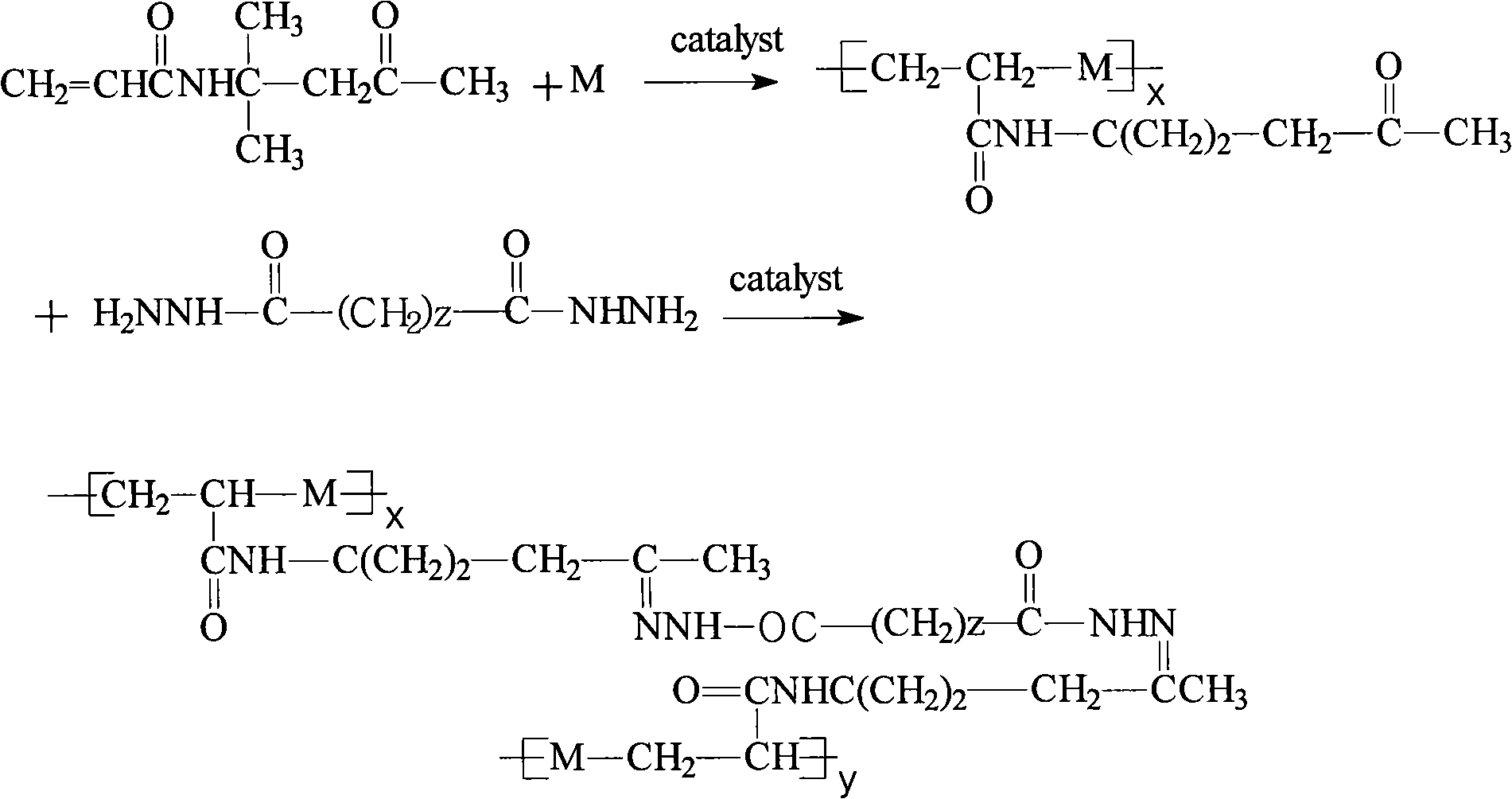

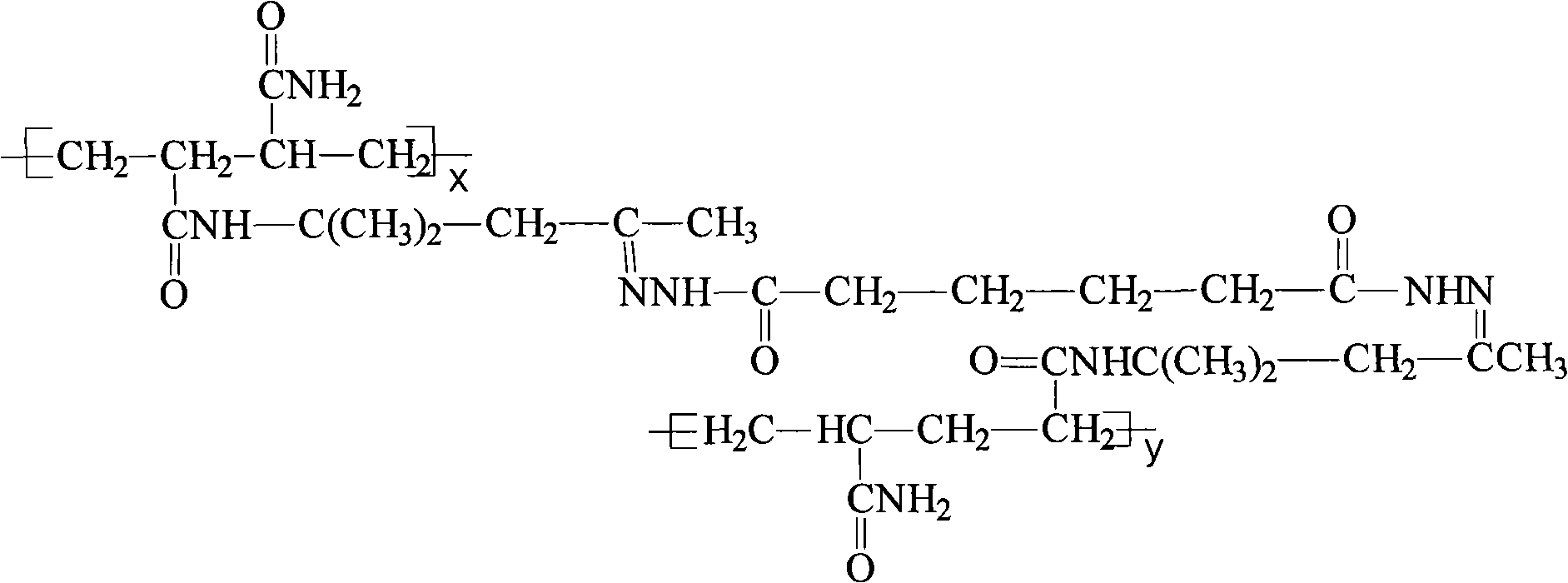

[0027] 1, the present invention is used for the preparation of the film-forming agent of seed coating

[0028] Add 8.5 g (0.05 mol) of 99% diacetone acrylamide, 7.1 g (0.1 mol) of 99% acrylamide, 0.1 g of ammonium persulfate, and 0.2 g of sodium dodecylbenzenesulfonate into a 250 mL three-neck flask with stirring , N, N, N', N'-tetramethylethylenediamine 0.1g, deionized water 75g. Start stirring, heat and control the reaction temperature at 40°C, and stir for 2 hours to obtain a copolymer of diacetone acrylamide and acrylamide, which is detected by infrared spectroscopy, nuclear magnetic resonance, gel permeation chromatography, and viscometer. The degree of polymerization of the product is 1400, and the copolymerization rate is 99.2%. Continue to drop about 30-40 drops per minute in the system and be 8.7g (0.005 moles) of adipic dihydrazide aqueous solution of 10% concentra...

experiment example 2

[0053] Experimental example 2. Preparation of film-forming agent for seed coating and its effect verification

[0054] 1, the present invention is used for the preparation of the film-forming agent of seed coating

[0055] Add 8.5 g (0.05 mol) of 99% diacetone acrylamide, 2.2 g (0.025 mol) of 99% methacrylic acid, 0.1 g of potassium persulfate, and nonylphenol polyoxyethylene ether (n= 20) 3g, 1g of 1,4-butanediamine, 52.8g of deionized water, start stirring, heat and control the reaction temperature at 60°C, stir for 2 hours to obtain the intermediate copolymer of diacetone acrylamide and methacrylic acid, use Infrared spectrometer, nuclear magnetic resonance instrument, gel permeation chromatography, viscometer and other tests show that the degree of polymerization of the copolymer is 1000, and the copolymerization rate is 99.5%. Continue to drop 33 g (0.025 moles) of 10% malonylhydrazide aqueous solution into the system, and continue to stir for 50 minutes after the additi...

experiment example 3

[0080] Experimental example 3. Preparation of film-forming agent for seed coating and its effect verification

[0081] 1, the present invention is used for the preparation of the film-forming agent of seed coating

[0082]Add 8.5 g (0.05 mol) of 99% diacetone acrylamide, 5 g (0.05 mol) of 99% methyl methacrylate, 4 g of benzoyl peroxide, and phenylethylphenol polyoxyethylene propylene into a 250 mL three-neck flask with stirring. Ether (m=10, n=20) 5g, ethylenediamine 0.2g, deionized water 54.5g, start stirring, heat and control the reaction temperature at 70°C, stir for 2 hours to obtain the intermediate diacetone acrylamide and methacrylic acid For the copolymer of methyl ester, detection by infrared spectrometer, nuclear magnetic resonance instrument, gel permeation chromatography, viscometer etc. shows that the degree of polymerization of the copolymer is 1300, and the copolymerization rate is 99.4%. Continue to drop 22 g (0.0125 mol) of 10% adipic hydrazide aqueous solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com