Polyurethane resin compound oil ink and method for manufacturing same

A technology of polyurethane resin and manufacturing method, which is applied in inks, household appliances, applications, etc., can solve the problems of narrow application scope, unfriendly aromatic hydrocarbon solvents, poor thermal stability, etc., and achieves wide application scope and solvent residual value without odor , good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

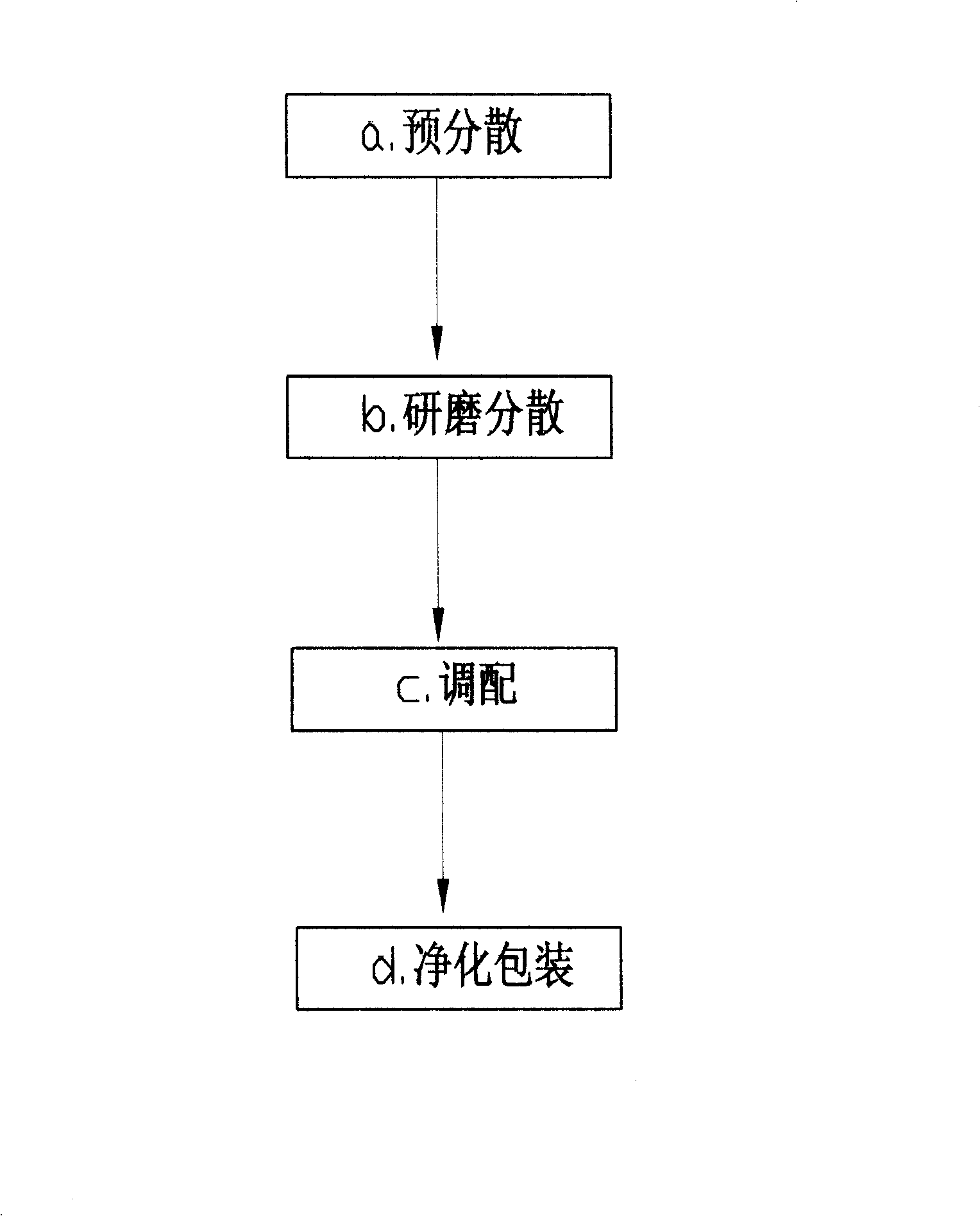

[0026] Polyurethane resin composite printing ink and manufacture method thereof are characterized in that polyurethane resin, vinyl chloride resin, solvent, pigment, dispersing aid are raw materials, and described solvent comprises toluene, methyl ethyl ketone, isopropanol, and specific formula ratio is:

[0027] Polyurethane resin liquid (30% solid content): 25%-40%

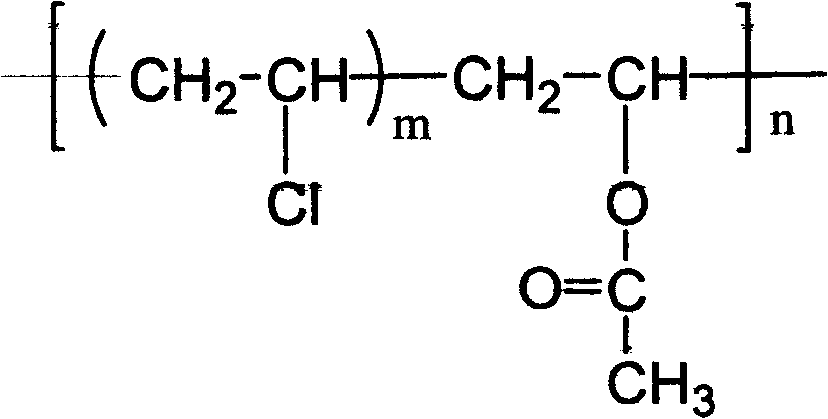

[0028] Vinyl resin: 0-4%

[0029] Pigment: 5%-25%

[0030] Dispersing aid: 0.2%-0.5%

[0031] Toluene: 0-20%

[0032] Butanone: 25%-35%

[0033] Isopropanol: 5%-15%

[0034] Polyurethane resin is formed by the stepwise addition polymerization reaction of diisocyanate and high molecular weight diol, and then extended by low molecular weight active hydrogen compounds such as polyamine or polyol with a molecular weight of less than 500.

[0035] Among them, the polymer diol can be all known polymer diols in the polyurethane industry, commonly used polyester diol, polyester amide diol, polyether diol, polyether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com