Surface active agent and oil-soluble viscosity reducer for crude oil as well as preparation method of surface active agent

A technology of surfactants and heavy oil viscosity reducers, which is applied in the direction of sulfonate preparation, chemical instruments and methods, and drilling compositions, etc. It can solve complex synthesis processes, limited viscosity reduction effects, poor temperature resistance, etc. problem, to achieve the effect of less dosage, improved viscosity reduction ability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

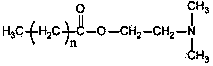

Method used

Image

Examples

Embodiment 1

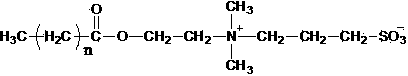

[0028] Mix 284g stearic acid (1mol) and 97.9g dimethylaminoethanol (1.1mol) evenly, add 0.3g concentrated sulfuric acid and toluene as a water-carrying agent, react at 150-180°C for 6 hours, until no water comes out, remove under reduced pressure Toluene and excess dimethylaminoethanol gave 2-(dimethylamino)ethyl stearate (n=16) 355g.

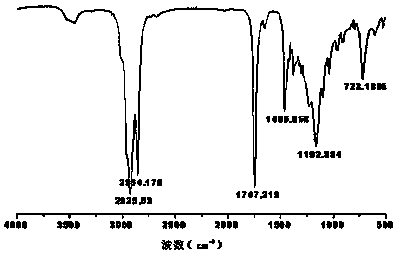

[0029] Dissolve 12.8g of propanesultone (0.105mol) in 30ml (24g) of acetone, add it into a 500ml three-necked flask equipped with a condenser, dropping funnel and electric stirring, then stir in a water bath at 10°C at constant temperature, and weigh 35.5 Dissolve g of 2-(dimethylamino)ethyl stearate (0.1mol) in 100ml (80g) of acetone and slowly drop it into a three-necked flask through a dropping funnel. After dropping, raise the temperature to 35°C for 24 hours. Then, it was filtered with a Buchner funnel to obtain 43.8 g of ethyl stearate ethyl sulfobetaine (n=16) as a white solid. Its infrared spectrum is as figure 1 shown.

[0030] fig...

Embodiment 2

[0032] Mix 284kg stearic acid (1000mol) and 97.9kg dimethylaminoethanol (1100mol) evenly, add 0.1kg concentrated sulfuric acid and toluene as water-carrying agent, react at 150-180°C for 6 hours until no water is separated out, remove toluene under reduced pressure and excess dimethylaminoethanol to obtain 2-(dimethylamino)ethyl stearate (n=16) 355kg.

[0033] Take 128kg propane sultone (1050mol) and dissolve it in 250 L (200kg) acetone, add 2m 3 In the reactor, then cooled to 10°C, under constant temperature stirring, 355kg of 2-(dimethylamino)ethyl stearate (1000mol) dissolved in 800 L (640kg) of acetone was slowly added to the reactor, adding After completion, the temperature was raised to 35° C. for 24 hours. Then, acetone was filtered off to obtain 461 kg of white solid stearate ethyl sulfobetaine (n=16).

Embodiment 3

[0035] Mix 256g of palmitic acid (1mol) and 97.9g of dimethylaminoethanol (1.1mol) evenly, add 0.3g of concentrated sulfuric acid and toluene as a water-carrying agent, and react at 150-180°C for 6 hours until no water comes out, then remove toluene under reduced pressure and excess dimethylaminoethanol to obtain 327g of palmitic acid-2-(dimethylamino)ethyl ester (n=14).

[0036]Dissolve 12.8g of propanesultone (0.105mol) in 30ml (24g) of acetone, add it into a 500ml three-neck flask equipped with a condenser, dropping funnel and electric stirring, then stir in a water bath at 10°C at constant temperature, and weigh 32.7 Dissolve g of 2-(dimethylamino)ethyl palmitate (0.1mol) in 80ml (64g) of acetone and slowly drop it into the three-necked flask through the dropping funnel. After the drop, raise the temperature to 35°C for 24 hours. Then, it was filtered with a Buchner funnel to obtain 40.3 g of ethyl stearate ethyl sulfobetaine (n=14) as a white solid.

[0037] Among them, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com