Worrkpiece polishing device

A workpiece and worktable technology, applied in the field of grinding equipment, can solve the problems of multi-processing cost and increase of clamping power mechanism, and achieve the effect of fast and convenient clamping and fixing of parts, stable adsorption effect, and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below by means of specific embodiments:

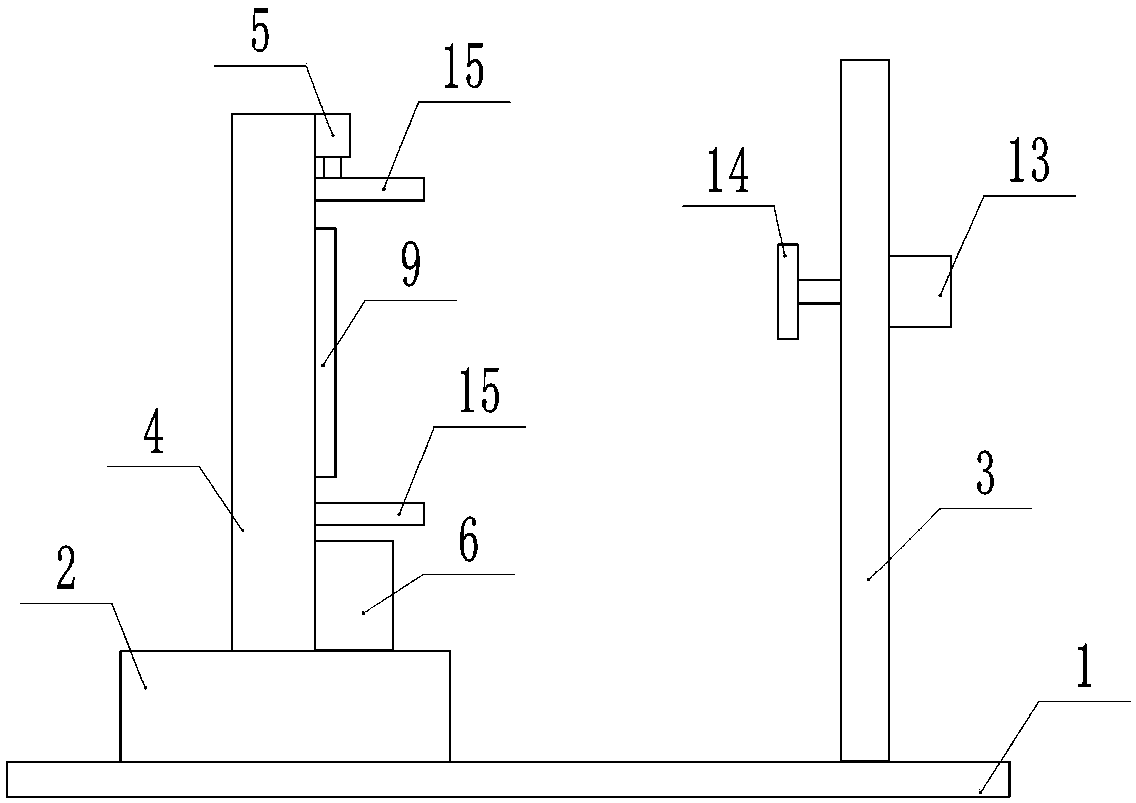

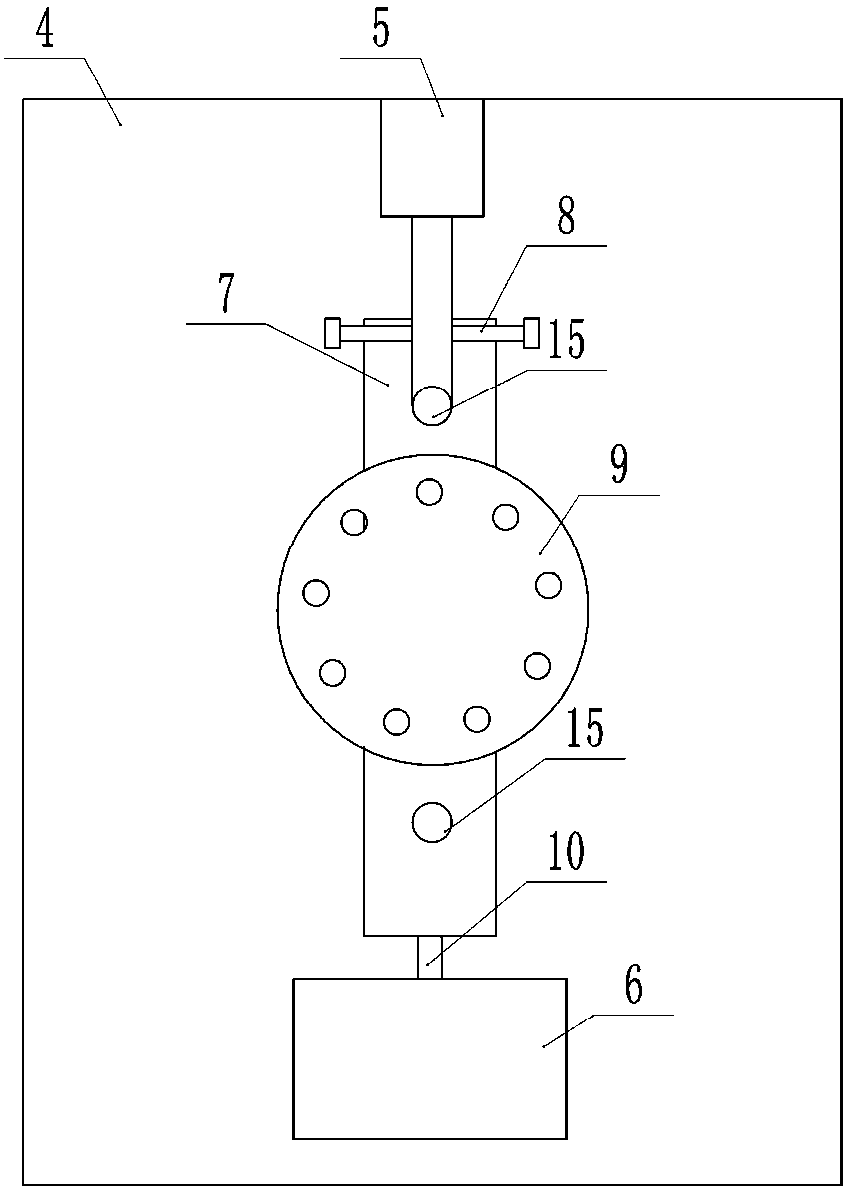

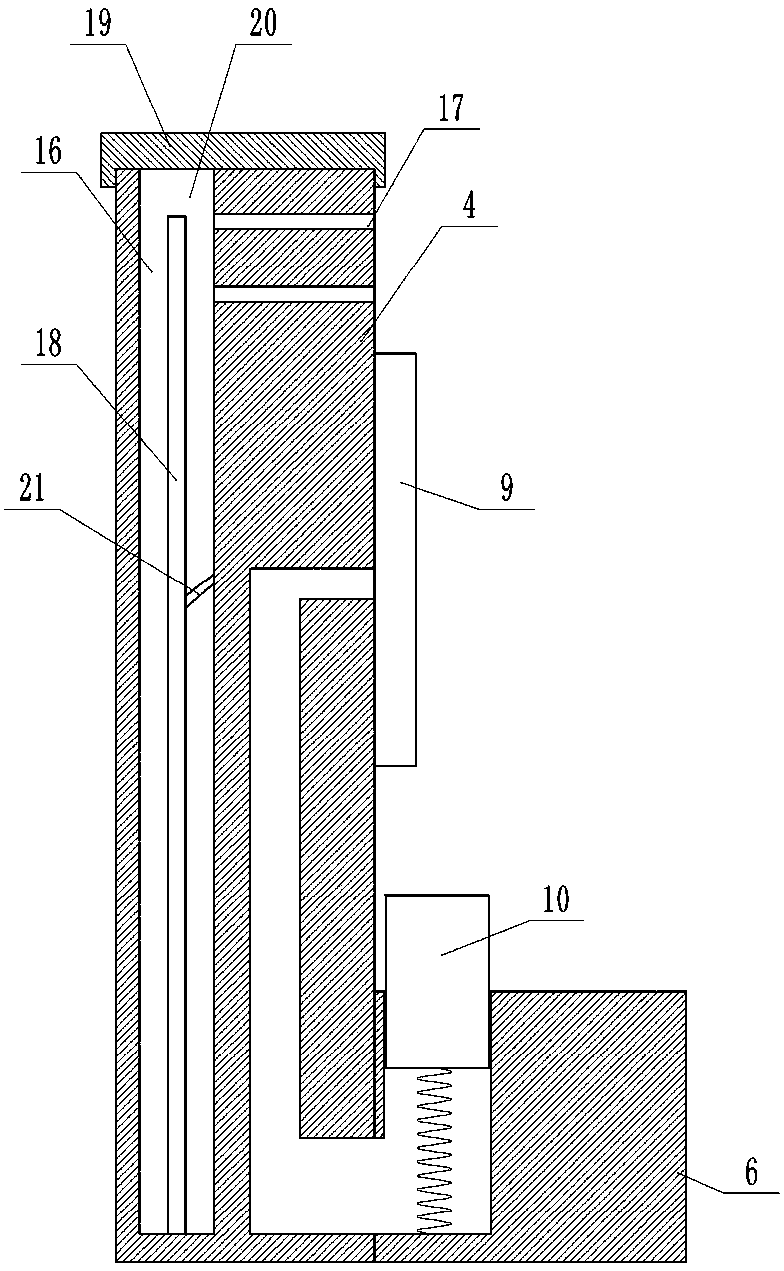

[0025] The reference signs in the drawings of the description include: frame 1, workbench 2, support plate 3, fixed plate 4, cylinder 5, fixed block 6, rack 7, first gear 8, suction cup 9, slide bar 10, convex Teeth 11, servo motor 13, grinding disc 14, cross bar 15, cavity structure 16, collection hole 17, electrostatic plate 18, upper cover 19, opening 20, scraper 21.

[0026] Such as figure 1 with image 3 As shown, a workpiece grinding device includes a frame 1, a workbench 2 is welded on the left part of the frame 1, a vertical fixing plate 4 is welded on the upper part of the workbench 2, and a cavity structure 16 is opened in the fixing plate 4 , the bottom of the cavity structure 16 is equipped with an electrostatic plate 18, and the electrostatic plate 18 is connected with an electrostatic line; the upper part of the fixed plate 4 is equipped with a cylinder 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com