Adsorption column with high sealing performance and high filtering performance

A filter performance and sealing technology, applied in the field of separation devices, can solve the problems of inconvenient transportation, installation, filling and discharging, and achieve the effects of saving workload, convenient transportation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

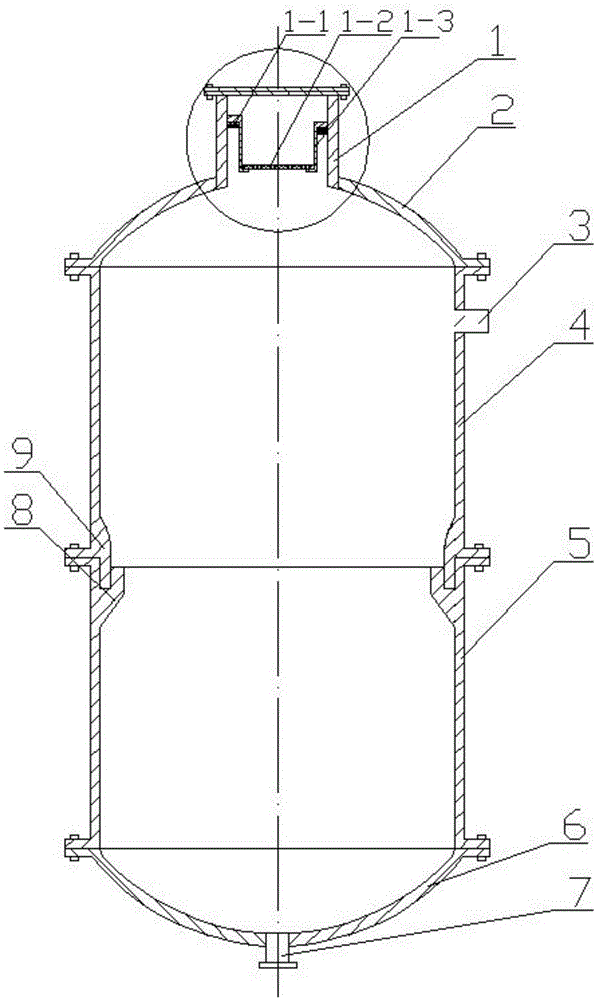

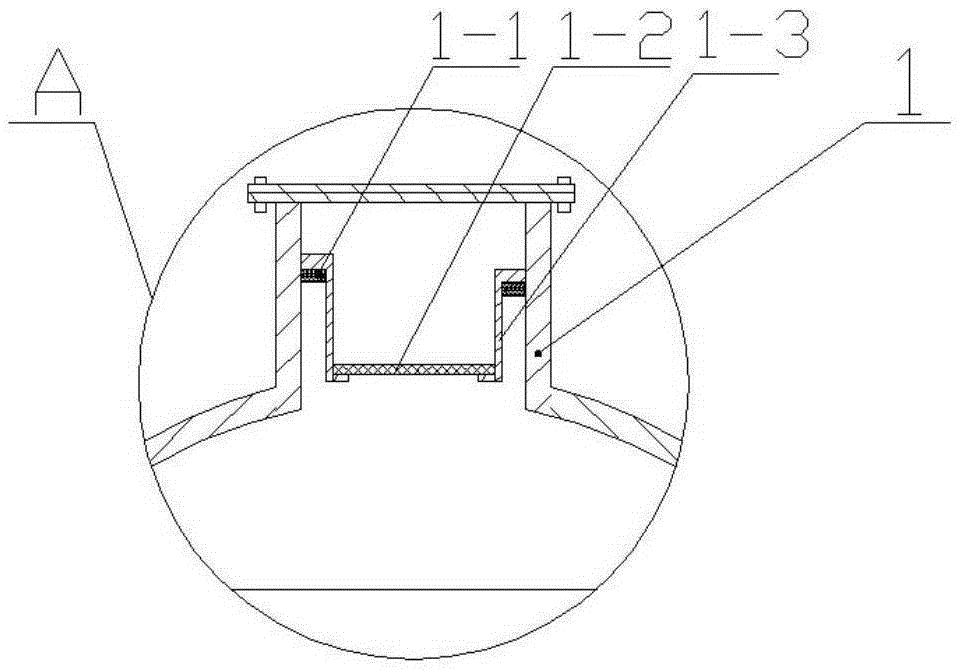

[0023] An adsorption column with good sealing performance and high filtration performance, comprising a column body, an upper cover 2, a lower cover 6, the lower cover is formed with a fluid outlet 7, and the upper cover and the lower cover are fixed to the column through flanges At the upper and lower ends of the cylinder, a fluid detection port 3 is formed on the side wall of the cylinder close to the upper cover. The cylinder is composed of two axial sections, the upper cylinder 4 and the lower cylinder 5. The truncation of the body is made with a disc extending coaxially to the outside of the cylinder. The discs of the upper and lower two sections of the cylinder are symmetrically arranged and hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com