Laminated adsorption ball for flue gas filtration

A layered and adsorption ball technology, which is applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of increasing the labor load of the staff, low use rate of adsorbent, and difficulty in entering the flue gas. The gas purification effect is good, the adsorption effect is improved, and the contact area is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

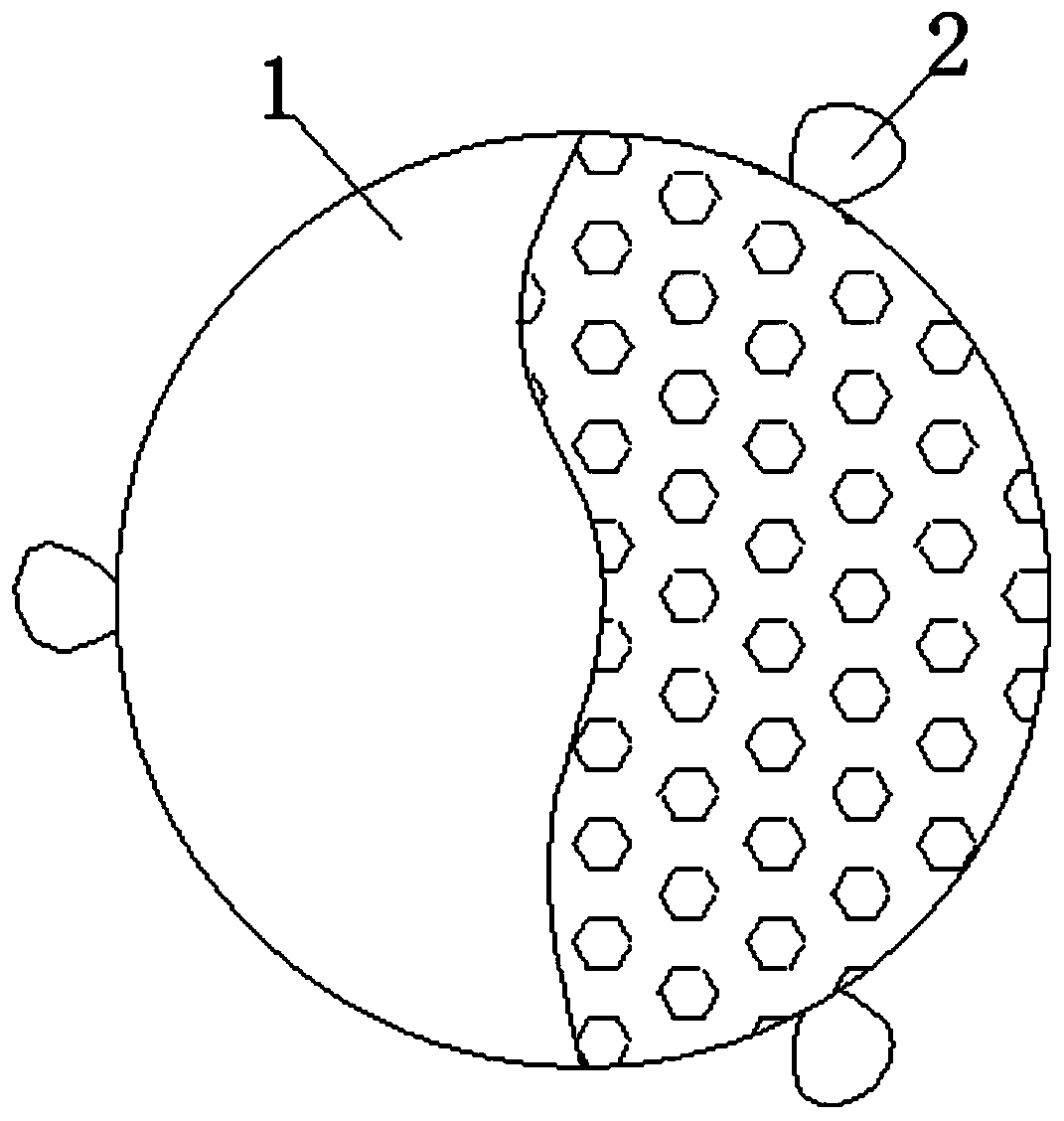

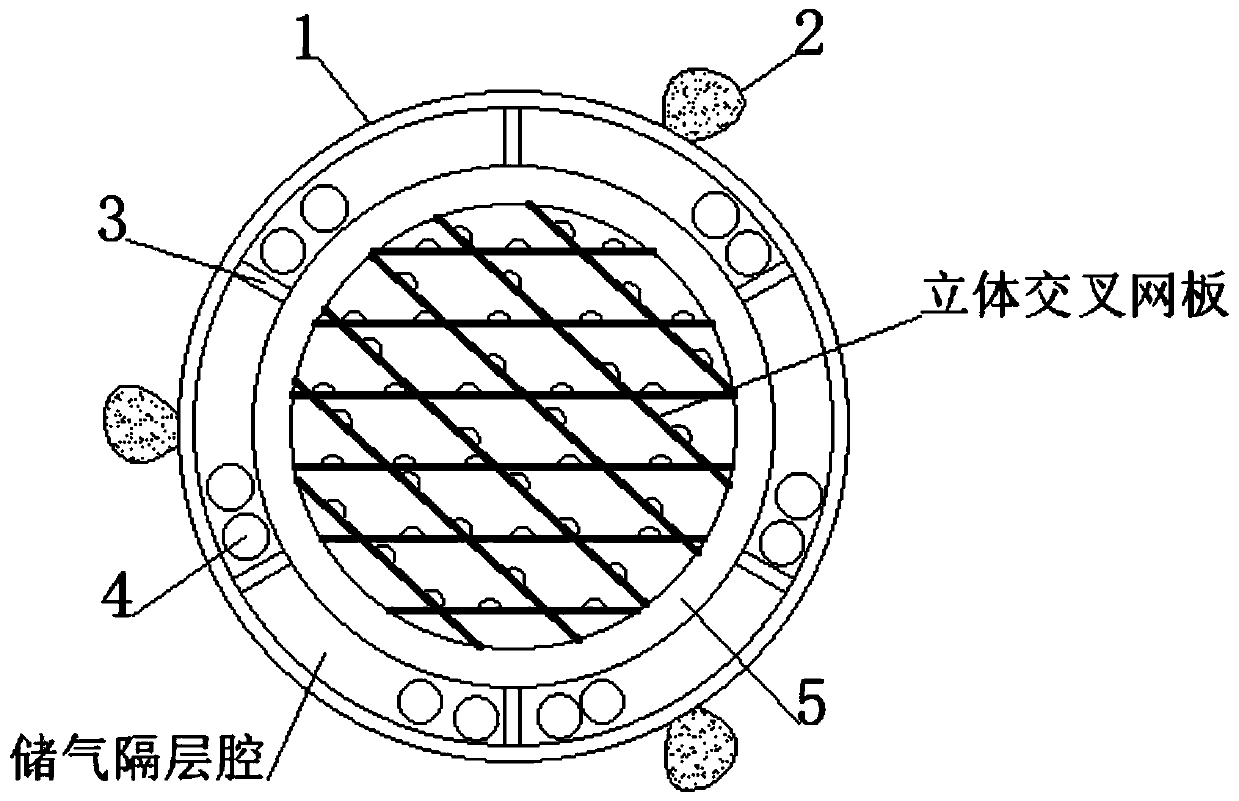

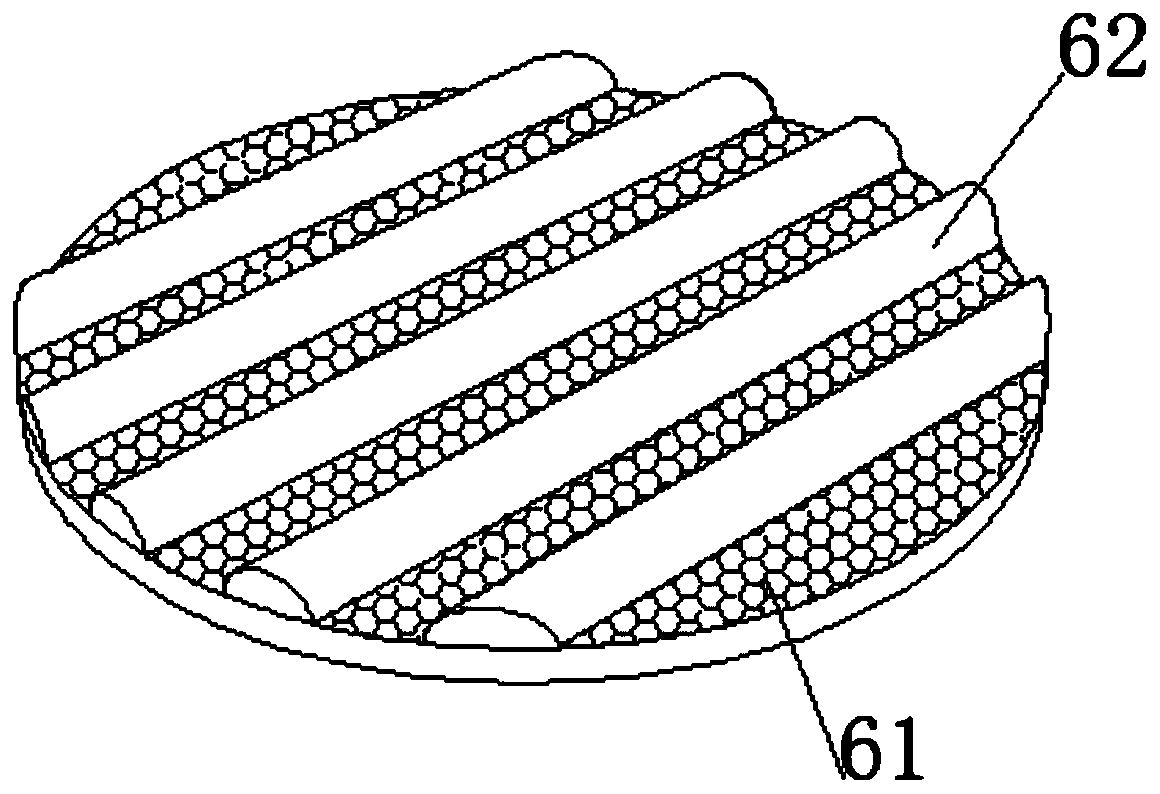

[0042] see Figure 1-2 , a stacked adsorption ball for flue gas filtration, comprising an outer transparent shell 1, the outer end of the outer transparent shell 1 is fixedly connected with a plurality of evenly distributed outer interval corners 2, the outer transparent shell 1 is a hollow structure, the outer transparent shell 1 The interior of the transparent shell 1 is provided with an inner transparent shell 5, and a plurality of evenly distributed annular partitions 3 are connected between the inner transparent shell 5 and the inner wall of the outer transparent shell 1, and between each adjacent two annular partitions 3 Both form a gas storage interlayer cavity, and two steel balls 4 are placed in the gas storage interlayer cavity, and a three-dimensional cross screen is arranged inside the inner transparent shell 5, and the three-dimensional cross screen includes a plurality of horizontal interlayer screens parallel to each other and A plurality of oblique interlayer n...

Embodiment 2

[0047] see Figure 6 , the first-level adsorption chamber and the second-level adsorption chamber can also be filled with internal and external connecting blocks 9 and adsorbents, the internal and external connecting blocks 9 are fixedly connected in the middle of the primary and secondary adsorption chambers, and the ends of the internal and external connecting blocks 9 exceed the volume of the adsorbent On the upper surface, the inner and outer connecting blocks 9 have a structure with many transparent holes inside, and the pore size of the transparent holes is smaller than the particle size of the adsorbent, so that the gas permeability and fluidity inside the adsorbent are better, thereby effectively ensuring that the adsorbent located inside It can simultaneously adsorb flue gas with the outer adsorbent. On the one hand, it can effectively improve the utilization rate and adsorption efficiency of the inner adsorbent. On the other hand, the two-way adsorption makes the adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com