Rolled steel pipe manufacturing process

A production process and technology for rolling steel pipes, which are applied in the directions of manufacturing tools, grinding workpiece supports, metal processing equipment, etc. Contact and separation, improve adsorption efficiency, ensure the effect of adsorption efficiency

Pending Publication Date: 2021-09-24

广西天正钢结构有限公司

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] During the production process of the existing rolled steel pipes, it is necessary to grind and remove the dust on both sides of the steel plate. The metal powder produced will be absorbed by the staff and is not easy to clean up, which makes the grinding process consume a lot of manpower and time, and reduces the preparation efficiency of rolled steel pipes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

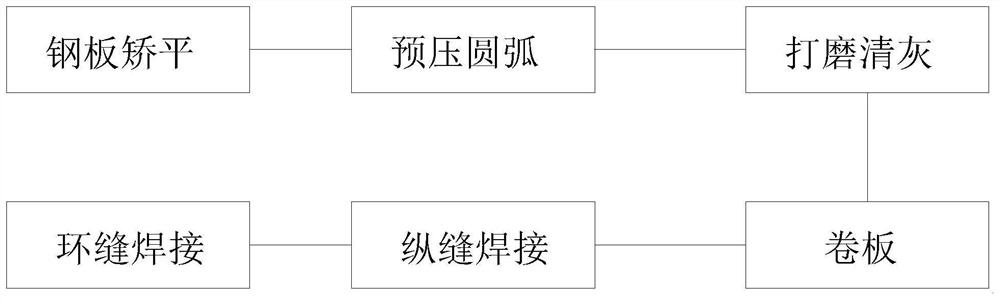

[0050] See figure 1 with figure 2 A roll steel pipe system, including the following steps:

[0051] S1, Steel Panel Laissibility: Use the correction machine to correct the steel plate;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

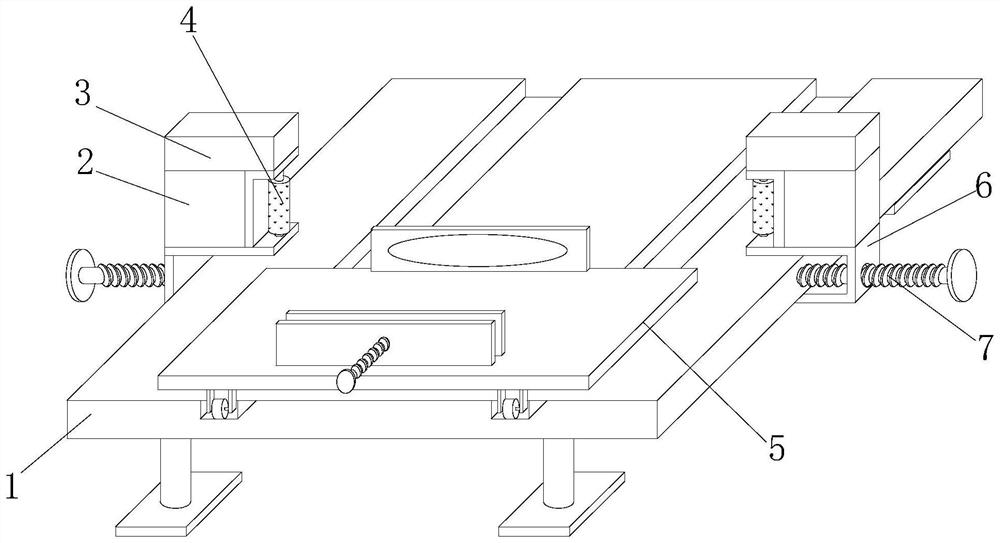

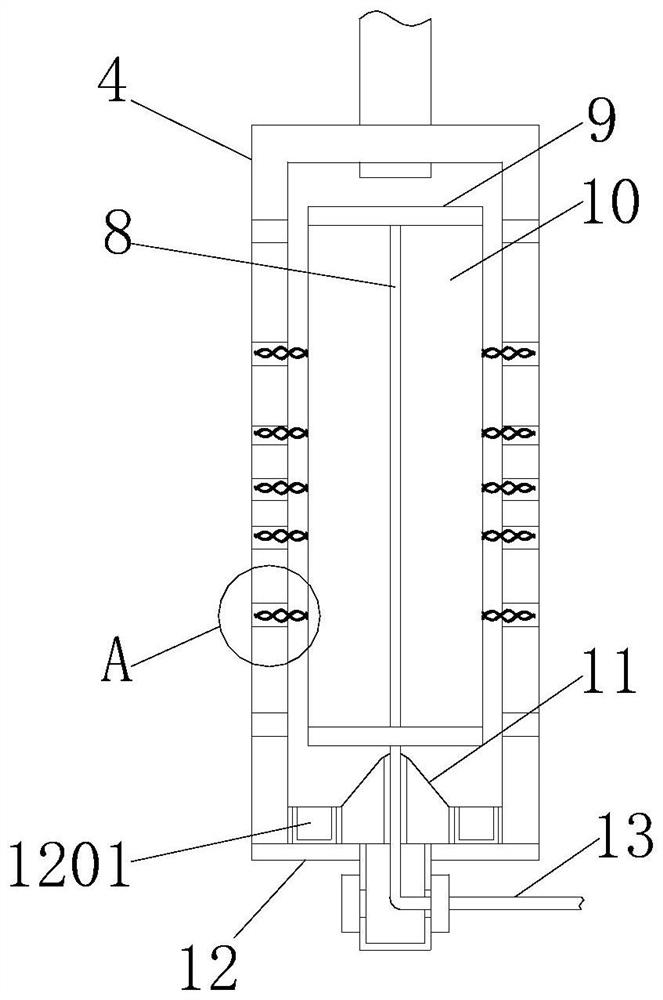

The invention discloses a rolled steel pipe manufacturing process, and belongs to the technical field of steel pipe processes. According to the rolled steel pipe manufacturing process, metal powder generated in the polishing process can be adsorbed by static electricity generated by friction between a filter screen and a polishing shell through expansion of the filter screen; and therefore, metal powder is prevented from being dispersed in the air to affect the health of operators in the polishing process; the adhesive force of the metal powder on the surface of the filter screen is obviously reduced after the filter screen returns to the original shape, and an air bag rebounds after the filter screen returns to drive the whole filter screen to shake, so that the falling rate of the metal powder on the surface of the filter screen is increased; the automatic dust removing function of the filter screen is achieved, fallen metal powder can fall into a recycling tank to be recycled, workers can recycle the metal powder conveniently, meanwhile, cold water is arranged in a polishing shell and can absorb heat generated in the polishing process, the polishing shell and the surface of a steel plate are prevented from being affected by high temperature, and the manufacturing efficiency of coil steel is improved.

Description

Technical field [0001] The present invention relates to the technical field of steel pipe process, and more particularly to a roll-made steel pipe. Background technique [0002] Oil, natural gas is an important source of national economic development. In the growing proportion in energy consumption, the steel pipe is transported into oil and natural gas, the most economical, safe, uninterrupted long distance transport tool. [0003] In the process of production, the existing roll steel pipe needs to be polished, and in the existing steel plate making process, the polishing and cleaning is generally divided into two steps, not only to extend the preparation process, but also grind The resulting metal powder will be absorbed by the staff and is not easy to clean, so that the grinding process consumes a lot of manpower and time, reduces the preparation efficiency of the curled steel pipe. Inventive content [0004] 1. Technical issues to be solved [0005] For the problems present ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B03C3/45B03C3/30B03C3/60B03C3/76B03C3/88B21C37/06B21C37/08B24B9/04B24B41/06B24B55/02B24B55/06

CPCB03C3/45B03C3/60B03C3/30B03C3/88B03C3/766B21C37/065B21C37/08B24B55/06B24B9/04B24B55/02B24B41/068Y02P70/10

Inventor 谢振宇

Owner 广西天正钢结构有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com