Heavy metal ion porous adsorbent as well as preparation method and application thereof

A technology of heavy metal ions and porous adsorbents, applied in the directions of alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of difficult separation of heavy metals, poor adsorption efficiency, inability to fix polyacrylic acid, etc. Good diffusivity, improved adsorption rate and usable capacity, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

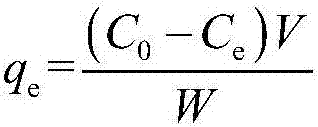

Method used

Image

Examples

Embodiment 1

[0048] The preparation method of the heavy metal ion porous adsorbent of this embodiment includes the following steps:

[0049] 1. Preparation of concentrated emulsion

[0050] 0.11g of initiator K 2 S 2 O 8 And 0.55g of electrolyte K 2 SO 4 Dissolve in deionized water to obtain a dispersed phase (ie water phase).

[0051] 4.0g of glycidyl ethacrylate, 3.0g of divinylbenzene and 3.0g of Tween 80 were mixed uniformly at a stirring speed of 500 rpm to obtain a continuous phase (ie organic phase); among them, Tween 80 was continuously The mass content in the phase is 30%.

[0052] The dispersed phase is added dropwise to the continuous phase to obtain a stable milky white concentrated emulsion; wherein the volume content of the dispersed phase in the concentrated emulsion is 88%.

[0053] 2. Preparation of porous polymers

[0054] The milky white concentrated emulsion is polymerized at 70° C. for 45 hours to obtain a polymerization product.

[0055] The polymerization product was washed alt...

Embodiment 2

[0077] The preparation method of the heavy metal ion porous adsorbent of this embodiment includes the following steps:

[0078] 1. Preparation of concentrated emulsion

[0079] 0.11g of initiator K 2 S 2 O 8 And 0.55g of electrolyte Na 2 SO 4 Dissolve in deionized water to obtain the water phase.

[0080] 4.0 g of glycidyl ethacrylate, 3.0 g of divinylbenzene and 2.3 g of Tween 80 were mixed uniformly at a stirring speed of 500 rpm to obtain an organic phase; wherein the mass content of Tween 80 in the organic phase Is 25%.

[0081] The water phase is added dropwise to the organic phase to obtain a stable milky white concentrated emulsion; wherein the volume content of the water phase in the concentrated emulsion is 90%.

[0082] 2. Preparation of porous polymers

[0083] The milky white concentrated emulsion is polymerized at 70° C. for 45 hours to obtain a polymerization product.

[0084] The polymerization product was washed alternately with deionized water and ethanol, and then dried...

Embodiment 3

[0091] The preparation method of the heavy metal ion porous adsorbent of this embodiment includes the following steps:

[0092] 1. Preparation of concentrated emulsion

[0093] 0.11g of initiator K 2 S 2 O 8 And 0.55g of electrolyte K 2 SO 4 Dissolve in deionized water to obtain the water phase.

[0094] 4.0g of glycidyl ethacrylate, 3.0g of divinylbenzene and 3.8g of Span 20 were mixed uniformly at a stirring speed of 500 rpm to obtain an organic phase; wherein the mass content of Span 20 in the organic phase Is 35%.

[0095] The water phase is added dropwise to the organic phase to obtain a stable milky white concentrated emulsion; wherein the volume content of the water phase in the concentrated emulsion is 90%.

[0096] 2. Preparation of porous polymers

[0097] The milky white concentrated emulsion is polymerized at 70° C. for 45 hours to obtain a polymerization product.

[0098] The polymerization product was washed alternately with deionized water and ethanol, and then dried at 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com