Method for preparing high-sound-absorptivity porous silicate material by molding and sintering inorganic salt

A technology of inorganic salts and silicates, which is used in the preparation of porous silicate materials with high sound absorption properties by inorganic salt mold sintering. Connectivity is not easy to achieve and other problems, to achieve the effect of good sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Method for preparing porous silicate materials with a porosity of 53% and an average pore diameter of 0.3mm

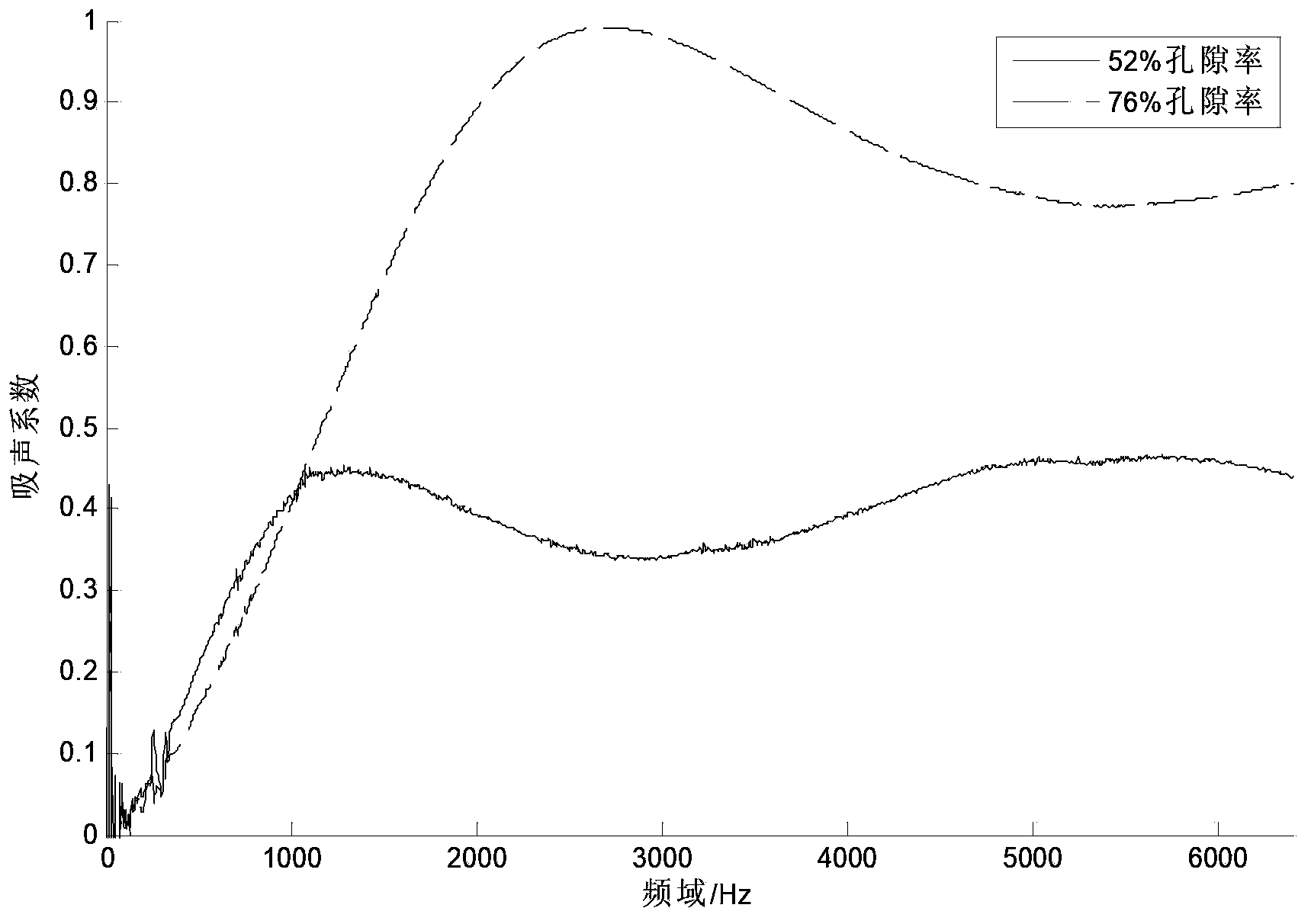

[0022] Refer to figure 1 The porous glass material in this embodiment is made by sintering ordinary silicate glass powder; the material sample is a cylindrical sintered glass material with a diameter of 29 mm, a thickness of 20 mm, and a porosity of 53%. The average pore size and pore morphology of porous glass are formed by sodium sulfate particles.

[0023] The method for preparing the porous glass material in this embodiment is characterized in that it comprises the following steps:

[0024] Step 1: Select ordinary glass and grind it into powder. The average particle size of the glass powder is less than 200 mesh and the mass is 15.4g;

[0025] Step 2: Select an inorganic salt with a melting point higher than the softening point of the glass. In this embodiment, the average particle size is 0.3mm and the mass is 8.4g sodium sulfate particles;

[0026] Step ...

Embodiment 2

[0029] Example 2: Method for preparing porous silicate materials with a porosity of 76% and an average pore size of 0.4mm (change the corresponding parameters in this example)

[0030] Refer to figure 1 The porous glass material in this embodiment is sintered from ordinary silicate glass powder; the material sample is a cylindrical sintered glass material with a diameter of 29mm, a thickness of 20mm, and a porosity of 76%. The average pore size and pore morphology of porous glass are formed by sodium sulfate particles.

[0031] The method for preparing the porous glass material in this embodiment is characterized in that it comprises the following steps:

[0032] Step 1: Select ordinary glass and grind it into powder. The average particle size of the glass powder is less than 300 mesh and the mass is 7.9g;

[0033] Step 2: Select an inorganic salt with a melting point higher than the softening point of the glass. In this embodiment, the average particle size is 0.4mm and the mass is 1...

Embodiment 3

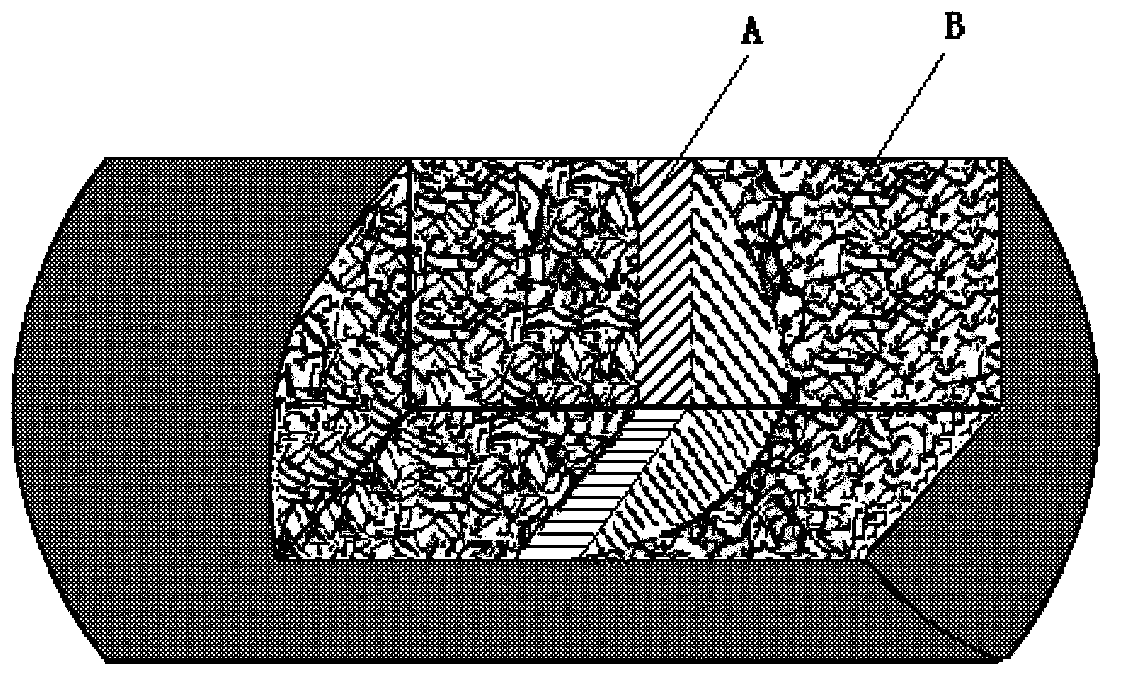

[0039] Example 3: Refer to figure 2 The porous glass material in this embodiment is made by sintering glass powder; the material is a diameter of 29mm and a thickness of 20mm. The porosity of part A is 52% and the porosity of part B is 75%. The whole is cylindrical. .

[0040] The method for preparing the porous glass material in this embodiment is characterized in that it comprises the following steps:

[0041] Step 1: Pre-forming of part A. Choose glass powder with an average particle size of less than 200 meshes and a mass of 6.3g and 0.1g boric acid; choose an average particle size of 0.3mm and a mass of 3.4g sodium sulfate particles, mix the above-mentioned selected materials uniformly, and load them with a diameter of 29mm In the mold, pre-pressed into a primary sample with a thickness of 8mm;

[0042] Step 2: Part B preparation of materials.

[0043] Choose glass powder with an average particle size of less than 200 mesh and a mass of 4.9g and 0.2g boric acid; choose an aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com