Preparation method of porous aluminum phosphate block

A technology of aluminum phosphate block and phosphoric acid, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry and other directions, can solve the problems that do not involve the preparation of aluminum phosphate block materials, etc., and achieve the effects of low equipment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1. A method for preparing a porous aluminum phosphate block, using aluminum chloride hexahydrate as an aluminum source, phosphoric acid as a phosphorus source, a mixture of deionized water and anhydrous methanol as a solvent, and propylene oxide as a condensate Adhesive accelerator, polyethylene oxide (average molecular weight 1×10 4 ) is a phase separation inducer; the following steps are carried out in sequence:

[0023] 1) Put 1.0g of aluminum chloride hexahydrate and 46mg of polyethylene oxide into the reaction bottle, add 1.0ml of deionized water, 1.0ml of anhydrous methanol and 0.3ml of phosphoric acid in turn, and stir until the polyethylene oxide (PEO) completely dissolved;

[0024] 2) Under ice bath conditions, evenly mix 2.00ml of propylene oxide into the solution obtained in the above step 1), and continue to stir vigorously (rotating at 400 rpm) until the propylene oxide is completely dissolved;

[0025] 3) Seal the reaction bottle and place it ...

Embodiment 2

[0030] Change the amount of propylene oxide in Step 2) of Example 1 from 2.00ml to 2.50ml; the rest is the same as Example 1.

[0031] In this embodiment 2, with respect to embodiment 1, the addition amount of PEO is kept constant, and the amount of propylene oxide (PO) is increased to 2.50ml. The porous aluminum phosphate block prepared in Example 2 began to form a bicontinuous pore structure, and the amount of PEO added was sufficient to cause phase separation of the sample, but the pores inside the sample were not uniform, and some pores were discontinuous. This is due to the fact that the gel time is earlier than the phase separation time due to the increase of PO addition, resulting in the formation of a porous structure with independent pores distributed on the continuous gel phase inside the sample. The sample is macroscopically opaque. According to the pore size distribution diagram of mesopores, the specific surface area (BET) = 39m 2 / g, total pore volume=0.12cc / g....

Embodiment 3

[0034] Change the amount of polyethylene oxide used in step 1) of Example 1 from 46 mg to 44 mg; the rest is the same as in Example 1.

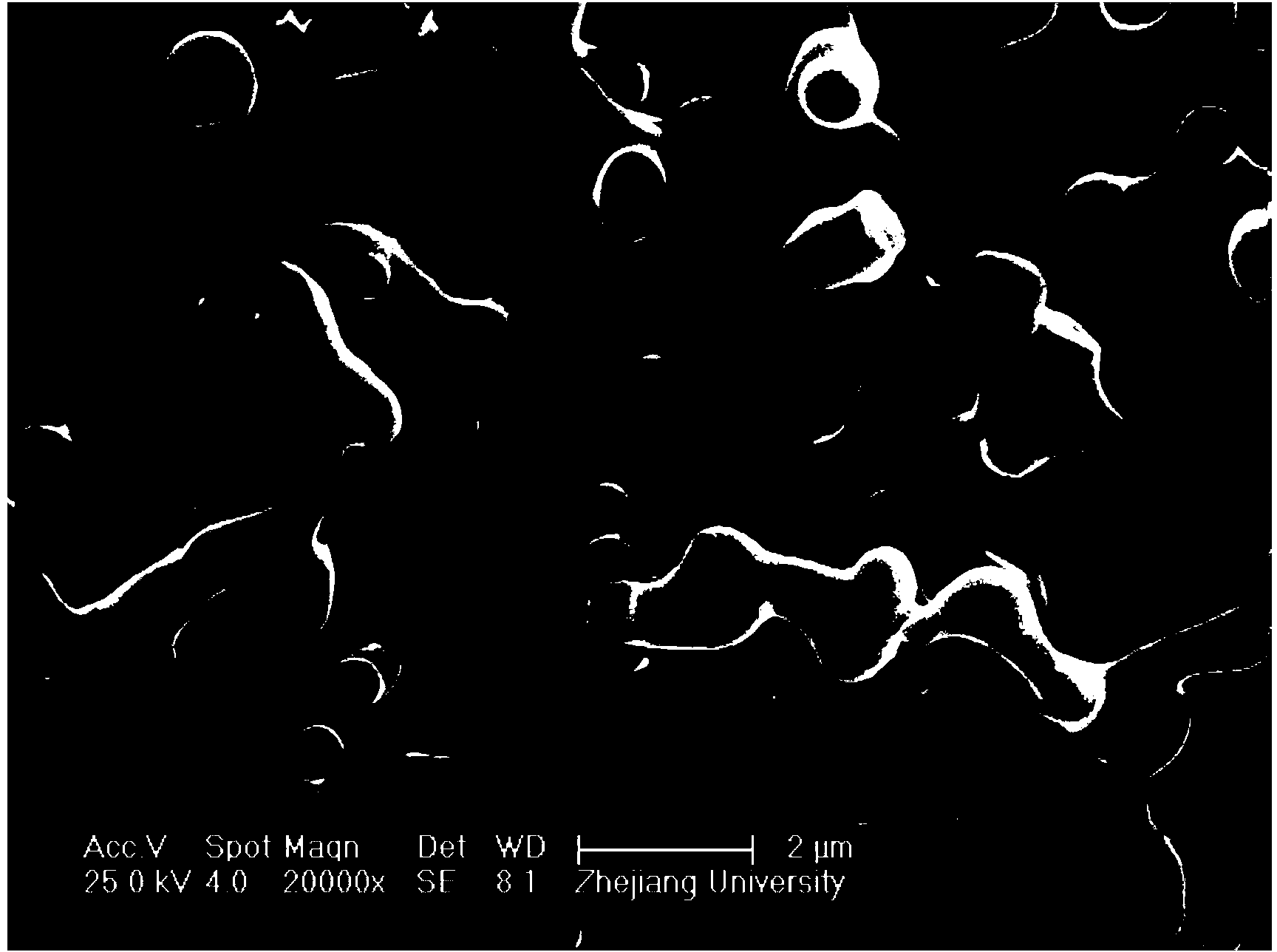

[0035] Example 3 is compared with Example 1, the PO content is kept constant, and the amount of PEO is changed to 44 mg. The SEM photos show that the interior does not form a porous structure, and it is still a flocculent aluminum phosphate aggregate. It should be that the addition of PEO is too small, resulting in phase separation later than the gel. The macroscopic appearance of the sample is translucent, not pure white. According to the pore size distribution diagram of mesopores, the specific surface area (BET) = 37m 2 / g, total pore volume=0.03cc / g. Large pores basically do not exist, and the pore size is mainly distributed in the range of 200-300nm; the bulk density of the block is 1.24g / cm 3 ; The porosity is 35.6%.

[0036] It was concluded that reducing the amount of polyethylene oxide would reduce the pore size and form a nanopo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com