Non-woven paper ion battery diaphragm and preparation method thereof

A technology of ion batteries and non-woven paper, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., and can solve the problems of inability to apply ion batteries, large aperture and thickness of non-woven paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

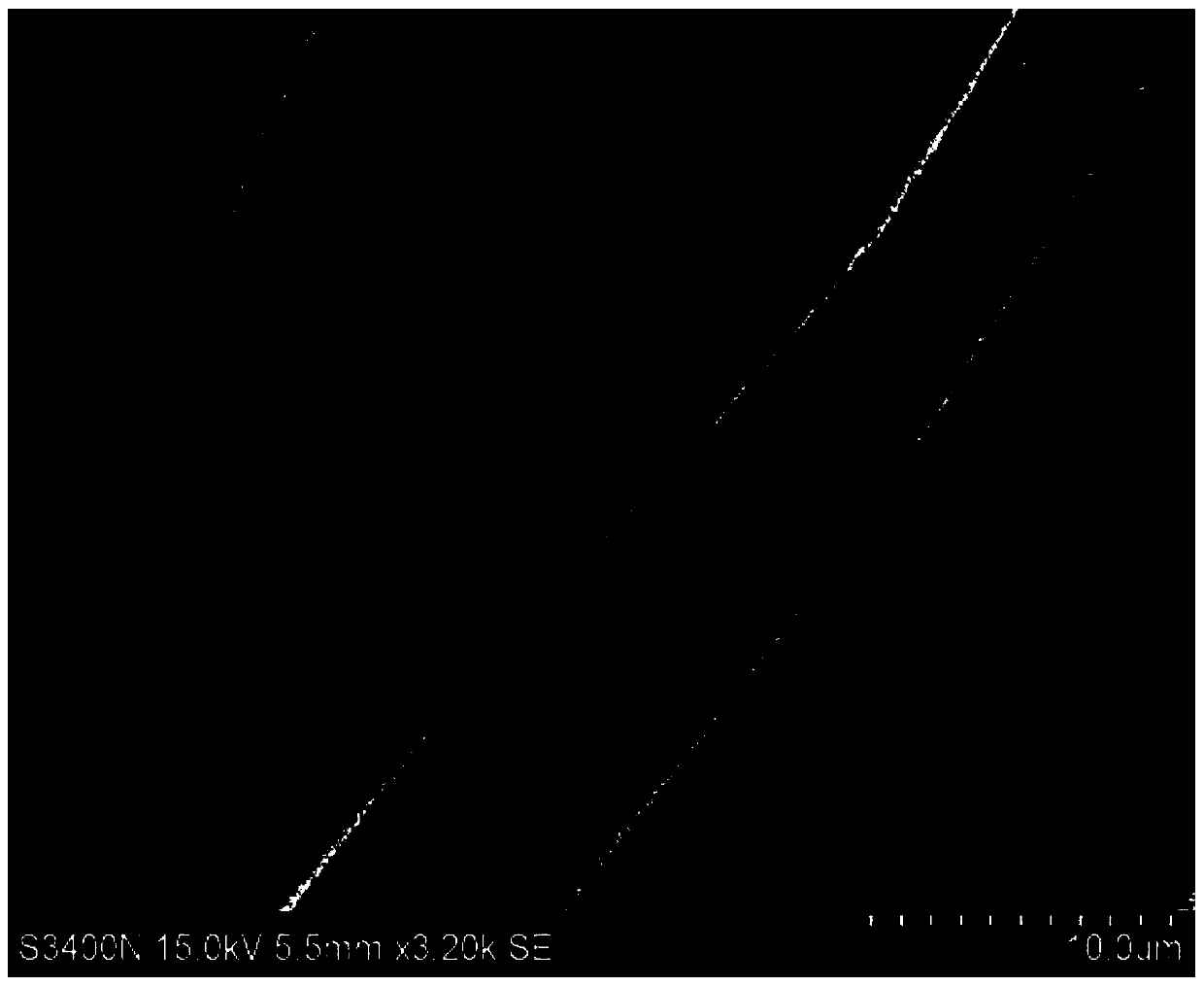

Image

Examples

Embodiment 1

[0040] The application provides the preparation method of the first non-woven paper ion battery diaphragm, and the specific steps are as follows:

[0041] At first the barium titanate 1g that particle diameter is 50nm joins in the acetone (100ml) and disperses uniformly, behind 1,4-butanediol and hexachlorocyclotriphosphazene (1,4-butanediol and hexachlorocyclotriphosphazene The molar ratio is 3:2) were added to acetone containing barium titanate, and reacted, the reaction conditions were 60 ° C stirring reaction for 4 hours, centrifuged to wash off the solvent and 80 ° C blast drying for 2 hours to obtain modified barium titanate powder ; Add modified barium titanate powder, sodium tripolyphosphate (0.1g), sodium lauryl sulfate (0.1g) to the DMSO solution of polyvinylidene fluoride PVDF (PVDF is 1g, DMSO is 50ml) and compounded Slurry and mix uniformly to obtain coating slurry.

[0042] The obtained coating slurry is coated on the surface of the non-woven paper, dried and th...

Embodiment 2

[0045] The application provides the second preparation method of non-woven paper ion battery separator, the specific steps are as follows:

[0046] At first the barium titanate 1g that particle diameter is 50nm joins in the acetone (100ml) and disperses uniformly, behind 1,4-butanediol and hexachlorocyclotriphosphazene (1,4-butanediol and hexachlorocyclotriphosphazene The molar ratio is 3:2) were added to acetone containing barium titanate, and reacted, the reaction conditions were 60 ° C stirring reaction for 4 hours, centrifuged to wash off the solvent and 80 ° C blast drying for 2 hours to obtain modified barium titanate powder ; Add modified barium titanate powder, sodium tripolyphosphate (0.1g), sodium lauryl sulfate (0.1g) to the DMSO solution of polyvinylidene fluoride PVDF (PVDF is 1g, DMSO is 50ml) and compounded Slurry and mix uniformly to obtain coating slurry.

[0047] The obtained coating slurry is coated on the surface of the non-woven paper, dried and then hot-...

Embodiment 3

[0049] The application provides the third preparation method of the non-woven paper ion battery separator, the specific steps are as follows:

[0050] At first the barium titanate 1g that particle diameter is 50nm joins in the acetone (100ml) and disperses uniformly, behind 1,4-butanediol and hexachlorocyclotriphosphazene (1,4-butanediol and hexachlorocyclotriphosphazene The molar ratio is 3:2) were added to acetone containing barium titanate, and reacted, the reaction conditions were 60 ° C stirring reaction for 4 hours, centrifuged to wash off the solvent and 80 ° C blast drying for 2 hours to obtain modified barium titanate powder ; Add modified barium titanate powder, sodium tripolyphosphate (0.1g), sodium lauryl sulfate (0.1g) to the DMSO solution of polyvinylidene fluoride PVDF (PVDF is 1g, DMSO is 50ml) and compounded Slurry and mix uniformly to obtain coating slurry.

[0051] The obtained coating slurry is coated on the surface of the non-woven paper, dried and then h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com