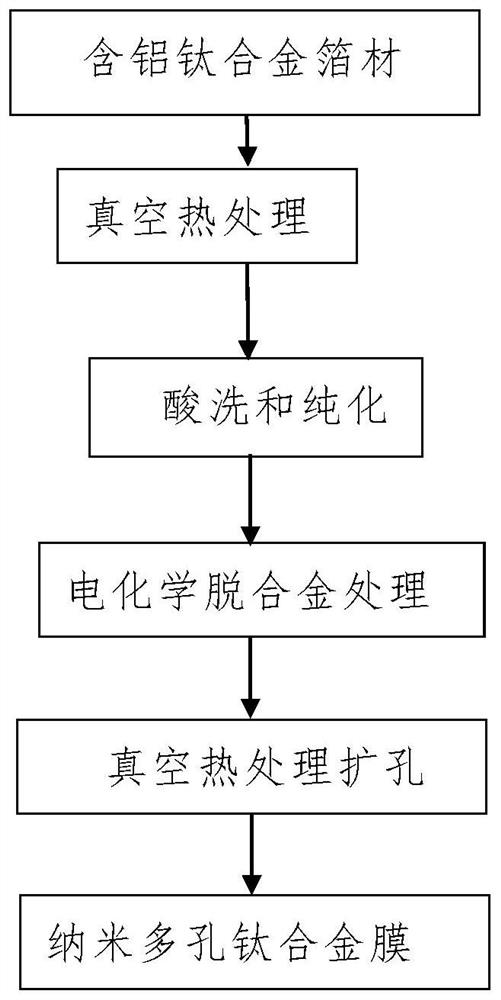

Preparation method of nano porous titanium alloy film

A nano-porous, titanium alloy technology, applied in the field of porous titanium alloy membrane preparation, to achieve the effects of eliminating stress, improving the uniformity of pore distribution, and reducing filtration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment includes the following steps:

[0039] Step 1. Put the Ti-6Al-4V titanium alloy foil with a thickness of 20 μm in a vacuum of 10 -2 Pa~10 -3 Vacuum heat treatment was carried out for 60 minutes under the condition of Pa and temperature of 980°C; the Ti-6Al-4V titanium alloy foil was prepared by smelting and rolling method

[0040] Step 2. Carry out surface pickling and purification to the Ti-6Al-4V titanium alloy foil after vacuum heat treatment in step 1; the process of said surface pickling and purification is: heat treated Ti-6Al-4V The titanium alloy foil was immersed in the mixed acid solution for cleaning for 5 seconds, then placed in deionized water, acetone and absolute ethanol for ultrasonic cleaning for 60 minutes, and then purified under a nitrogen atmosphere of 0.6 Pa for 60 minutes after removal; the mixed acid solution was prepared by HF solution with a mass concentration of 38%, HNO with a mass concentration of 65% 3 The solution and wa...

Embodiment 2

[0048] This embodiment includes the following steps:

[0049] Step 1. Put the Ti-6Al-7Nb titanium alloy foil with a thickness of 200 μm in a vacuum of 10 -2 Pa~10 -3 Pa, the temperature is 700 ℃ under the conditions of vacuum heat treatment for 240min;

[0050] Step 2. Carry out surface pickling and purification to the Ti-6Al-7Nb titanium alloy foil after vacuum heat treatment in step 1; the process of said surface pickling and purification is: heat treated Ti-6Al-7Nb The titanium alloy foil was immersed in the mixed acid solution for cleaning for 5 seconds, and then placed in deionized water, acetone and absolute ethanol for ultrasonic cleaning for 60 minutes respectively. After taking it out, it was purified under a nitrogen atmosphere of 1.0 Pa for 40 minutes; the mixed acid solution was prepared by HF solution with a mass concentration of 38%, HNO with a mass concentration of 65% 3 The solution and water are mixed according to the volume ratio of 1:5:4, and the temperat...

Embodiment 3

[0058] This embodiment includes the following steps:

[0059] Step 1. Put the Ti-3Al-2.5V titanium alloy foil with a thickness of 60 μm in a vacuum of 10 -2 Pa~10 -3 Pa, the temperature is 1000 ℃ under the conditions of vacuum heat treatment for 100min;

[0060] Step 2. Carry out surface pickling and purification to the Ti-3Al-2.5V titanium alloy foil material after vacuum heat treatment in step 1; the process of said surface pickling and purification is: heat treated Ti-3Al- The 2.5V foil was immersed in the mixed acid solution for cleaning for 5 seconds, then placed in deionized water, acetone and absolute ethanol for ultrasonic cleaning for 60 minutes, and then purified under a nitrogen atmosphere of 0.8 Pa for 20 minutes after removal; the mixed acid solution was prepared by HF solution with a mass concentration of 38%, HNO with a mass concentration of 65% 3 The solution and water are mixed according to the volume ratio of 1:5:4, and the temperature of the mixed acid so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com