Monolithic silica gel adsorption column, and solid phase extraction device and application thereof

A technology of extraction device and solid phase extraction column, which is applied in solid solvent extraction, measuring devices, and other chemical processes, can solve problems that have not been reported before, and achieve the effects of ensuring adsorption efficiency, low environmental requirements, and using a small amount of solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

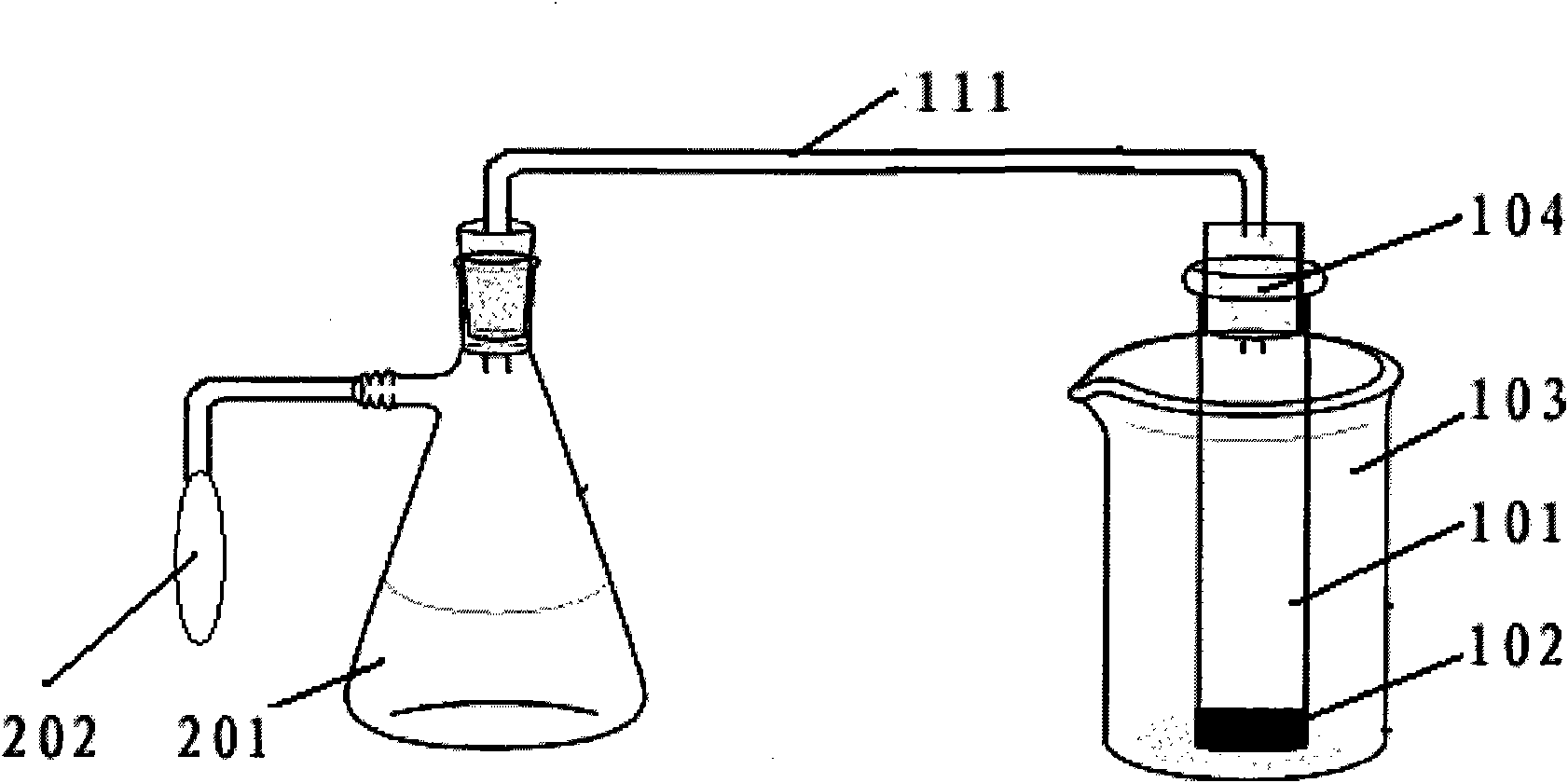

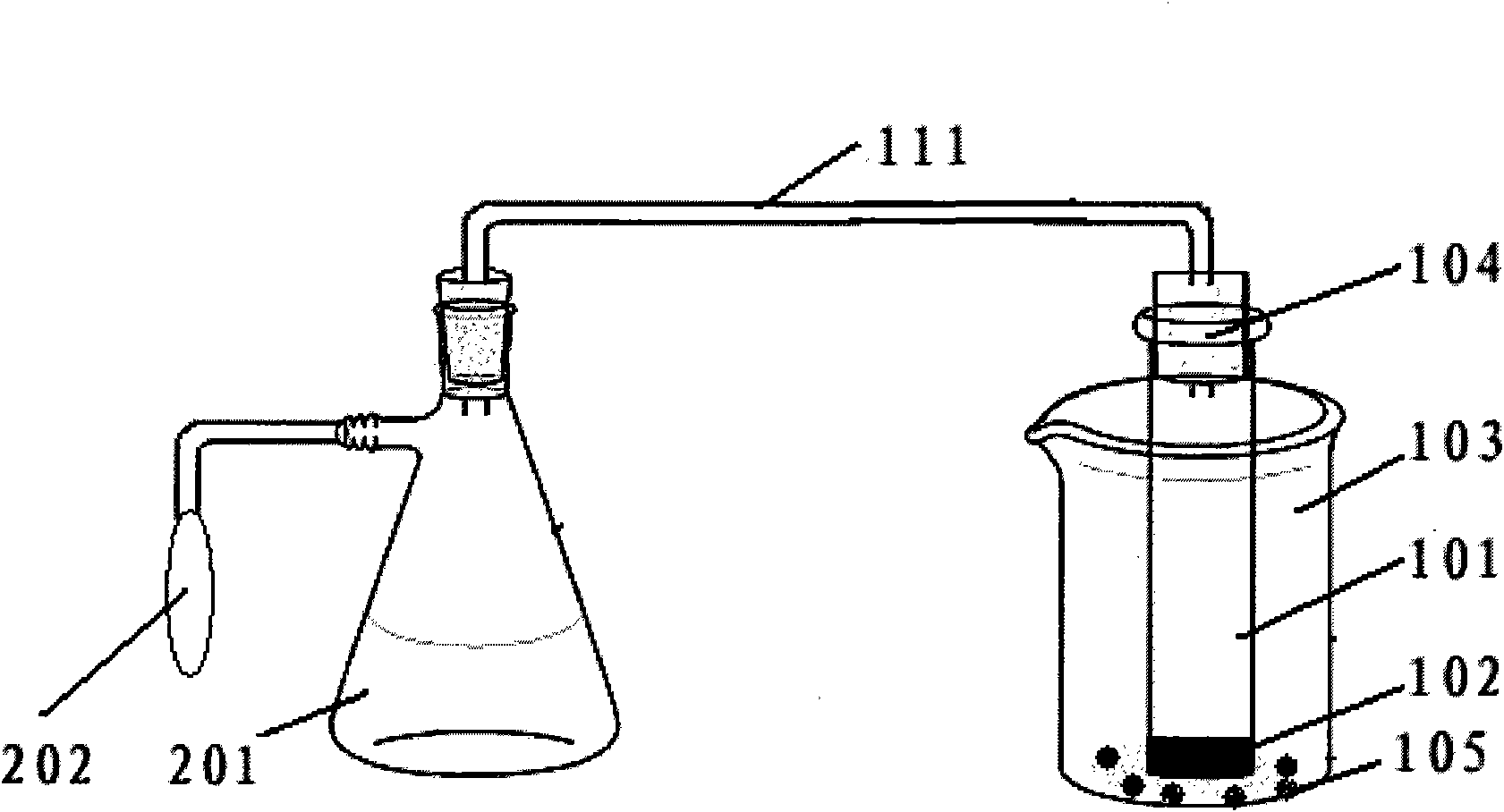

Method used

Image

Examples

Embodiment 1

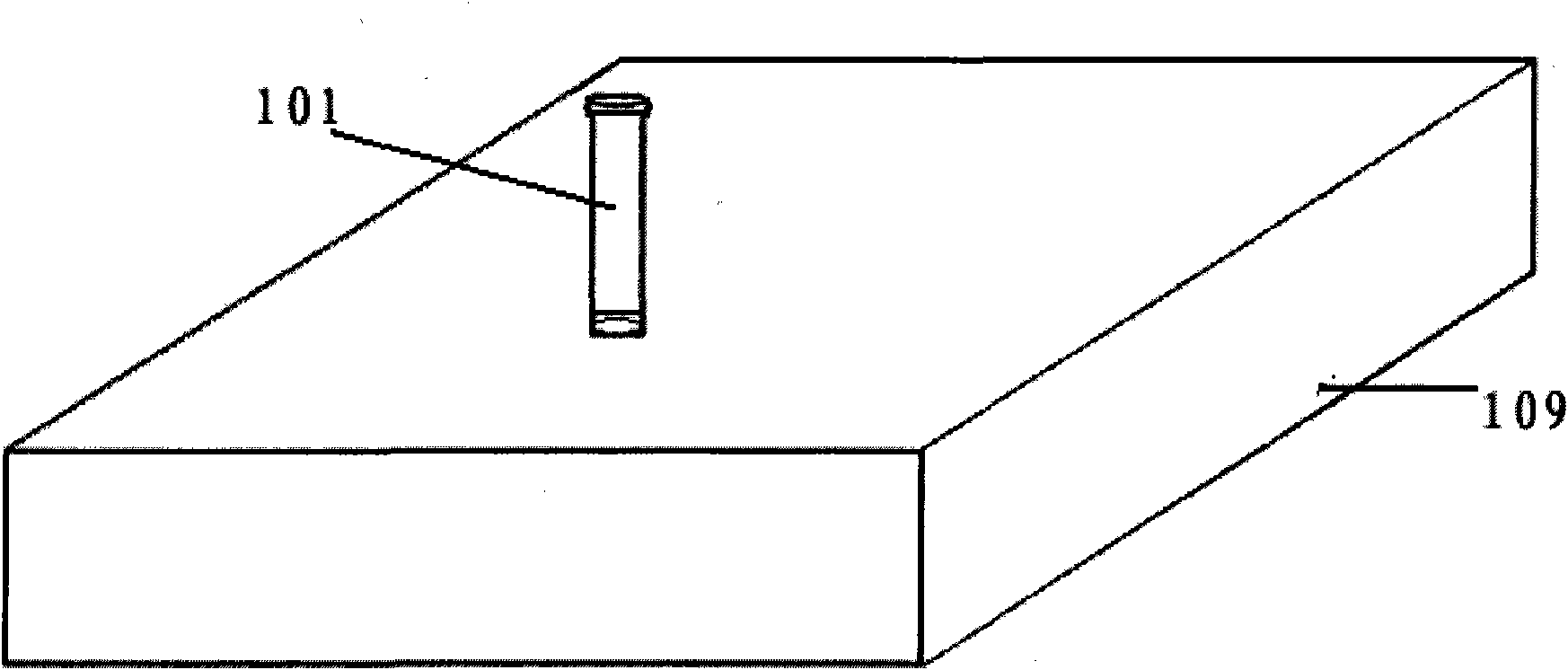

[0031] Silica monolithic adsorption column preparation

[0032] Weigh 1.2830g of polyethylene glycol (MW: 10000), dissolve it in 20ml of 0.01M acetic acid solution, add 10ml of tetramethylsiloxane under ice bath, and stir for 40min at the same temperature. After the tetramethylsiloxane solified mixture was ultrasonically degassed, it was poured into a straight tube mold (the straight tube mold is a glass tube with a diameter of 30 mm and a length of 15 cm). At 40°C, stand for 2 hours to gel. Aged for 24 hours at the same temperature. It was then treated with 0.01 M aqueous ammonium hydroxide at 120 °C for 9 hr. The wet silica gel column was soaked in 0.1M HNO3 for 3 hours, water for 2 hours, and 60% (volume ratio) N, N-dimethylformamide aqueous solution for 5 hours. Finally, the wet silica gel column was dried at a constant temperature of 60°C for 10 hours, and then burned at 700°C for 2 hours. Cut a 1cm long cylinder and set aside.

Embodiment 2

[0034] Silica monolithic adsorption column preparation

[0035] Weigh 1.2830g of polyethylene glycol (MW: 10000), dissolve it in 20ml of 0.01M acetic acid solution, add 10ml of tetramethylsiloxane under ice bath, and stir for 40min at the same temperature. After the tetramethylsiloxane solified mixture is ultrasonically degassed, it is poured into a straight tube mold (the straight tube mold is a plastic tube with a diameter of 50 mm and a length of 20 cm). At 45°C, stand for 2 hours to gel. Aged for 24 hours at the same temperature. It was then treated with 0.01 M aqueous ammonium hydroxide at 120 °C for 9 hr. The wet silica gel column was soaked in 0.1M HNO3 for 3 hours, water for 2 hours, and 60% (volume ratio) N, N-dimethylformamide aqueous solution for 5 hours. Finally, the wet silica gel column was dried at a constant temperature of 50°C for 12 hours, and then burned at 800°C for 1 hour. Cut a 15cm cylinder and set aside.

Embodiment 3

[0037] Silica monolithic adsorption column preparation

[0038] Weigh 1.2830g of polyethylene glycol (MW: 10000), dissolve it in 20ml of 0.01M acetic acid solution, add 10ml of tetramethylsiloxane under ice bath, and stir for 40min at the same temperature. After the tetramethylsiloxane solified mixture was ultrasonically degassed, it was poured into a straight tube mold (the straight tube mold is a metal tube with a diameter of 6 mm and a length of 5 cm). At 40°C, stand for 2 hours to gel. Aged for 24 hours at the same temperature. It was then treated with 0.01M aqueous ammonium hydroxide at 100°C for 11 hr. The wet silica gel column was soaked in 0.1M HNO3 for 3 hours, water for 2 hours, and 60% (volume ratio) N,N-dimethylformamide aqueous solution for 5 hours. Finally, the wet silica gel column was dried at a constant temperature of 60°C for 10 hours, and then burned at 700°C for 2 hours. Cut a 1cm cylinder and set aside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com