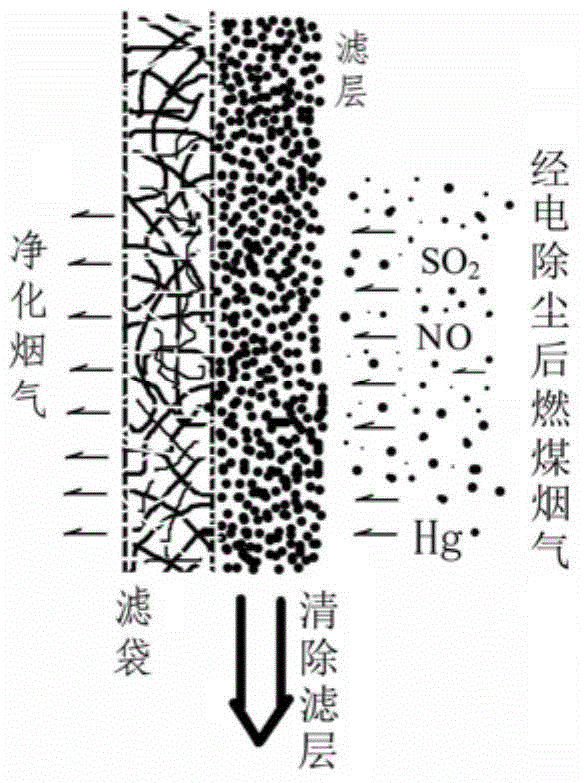

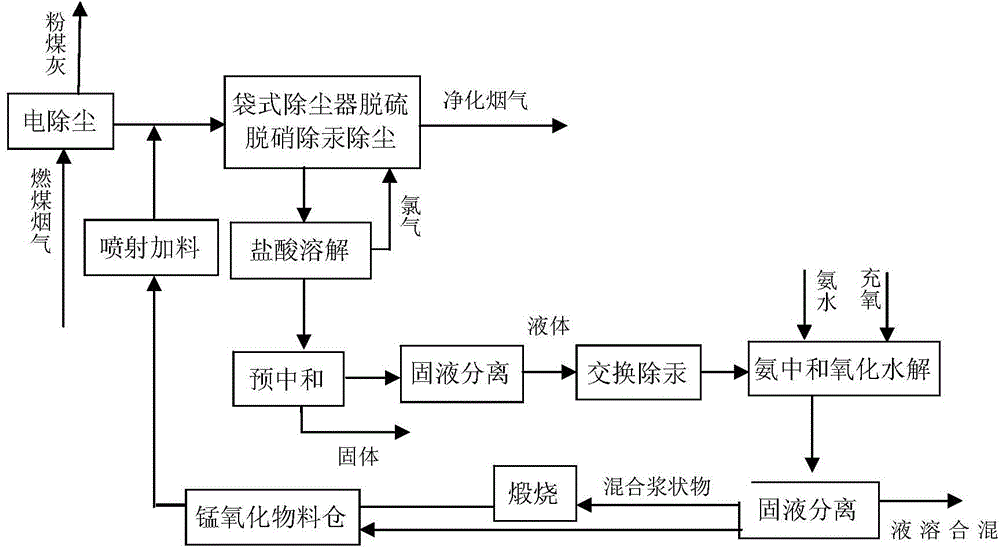

Method for synchronous desulfurization, denitrification, mercury removal and dust removal in bag type dust collector

A bag filter, desulfurization and denitrification technology, applied in the direction of chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve problems such as difficult to handle, corrosion, blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In the present invention, manganese oxide is used as the reactive material in the bag filter to realize synchronous desulfurization, denitrification and dust removal, and the simulation experiment is performed as follows:

[0059] a, with Hg-NO / Ar 2 , SO 2 / Ar 2 , Cl 2 / Ar 2 , pure oxygen as the standard gas, high-purity Ar 2 In order to dilute the gas, the simulated gas is prepared by adjusting the flow rate with a mass flow meter respectively. The mixed gas contains [NO]=500ppm, [SO 2 ]=500ppm, [O 2 ]=5vol%, [Hg]=0.02PPm, [Cl 2 ]=1.0PPm, the rest is argon. Add 50PPm of soot and 500PPm of manganese oxide to the mixed gas by air entrainment;

[0060]b. The simulated flue gas enters the tube furnace, and the high temperature zone in the tube is filled with 0.5cm thick quartz wool instead of the filter cloth. The tube temperature is controlled between 200 and 220°C, and the desulfurization, denitrification, dust and mercury removal experiments are carried out. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com