Continuous monitoring device and method of gaseous elemental mercury concentration

A monitoring device and a technology for elemental mercury, which are applied in measurement devices, color/spectral property measurement, material analysis by optical means, etc., can solve the problems of high cost, low sensitivity and complex system, and achieve low cost and simple composition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

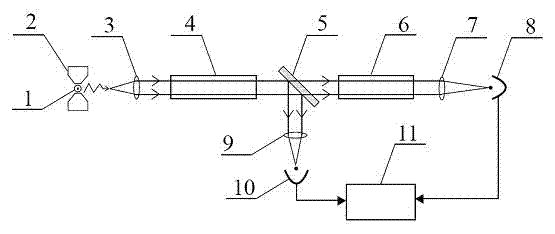

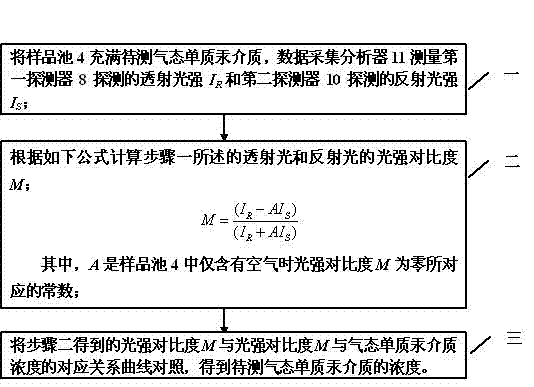

[0014] Specific implementation mode one, combine figure 1 Describe this embodiment, the continuous monitoring device of gaseous elemental mercury concentration, it is made of mercury element lamp 1, magnet 2, collimator lens 3, sample cell 4, beam splitter 5, reference cell 6, first convex lens 7, first detector 8. Composed of a second convex lens 9, a second detector 10, and a data acquisition analyzer 11, the mercury element lamp 1 is placed in the magnetic field of the magnet 2, and is arranged at the focal point of the collimating lens 3. The detection of the first detector 8 The surface coincides with the focal plane of the first convex lens 7, the detection surface of the second detector 10 coincides with the focal plane of the second convex lens 9, the output light of the mercury element lamp 1 is incident on the collimator lens 3, and is transmitted through the collimator lens 3 to obtain Parallel light, the parallel light enters the beam splitter 5 after passing thr...

specific Embodiment approach 2

[0018] Specific implementation mode two, combine figure 1 This embodiment is described. The difference between this embodiment and the first embodiment is that the beam splitter 5 is a semi-reflective and semi-transmissive beam splitter.

specific Embodiment approach 3

[0019] Specific implementation mode three, combine figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is that the saturation concentration per meter of elemental mercury gas in the reference pool 6 is 0.2 ~ 20mg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com