Method and device for promoting simultaneous removal of mercury and fine particulate matters during wet flue gas desulfurization

A technology for wet flue gas desulfurization and fine particles, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve the problems of high water vapor content and ineffective removal, and achieve huge economic and social benefits. Wide application prospects and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

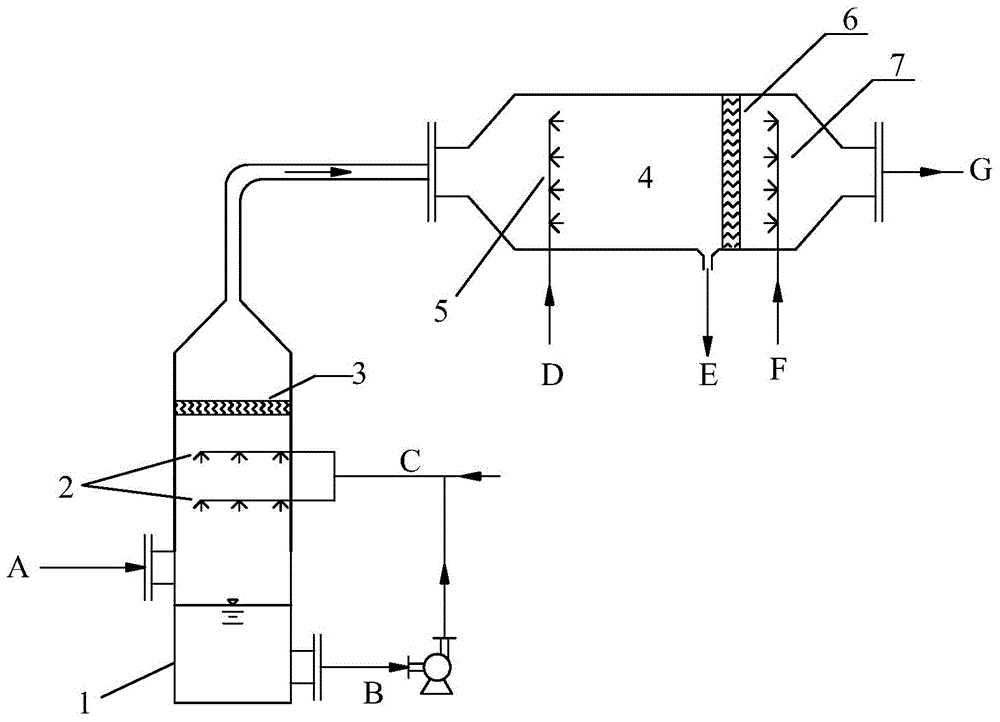

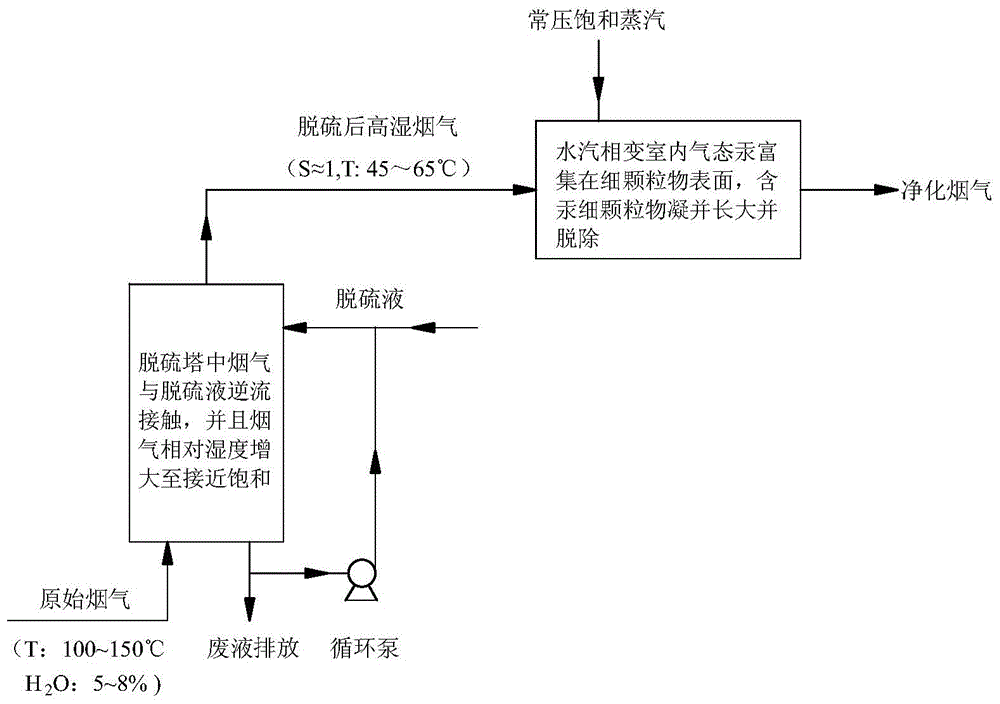

Embodiment 1

[0031] The original flue gas flow generated by the fully automatic coal-fired boiler is 150Nm 3 / h, the number concentration of fine particles is 5.02×10 7 Pieces / cm 3 , the total mercury concentration is 1.50 μg / m 3 ; After limestone-gypsum wet desulfurization, the outlet flue gas temperature of wet desulfurization tower 1 is reduced from 120 ℃ to 55 ℃, and the relative humidity is 97%; it enters the water vapor phase change chamber 4, and a wire mesh is installed at the outlet of the phase change chamber to remove the gas. Mist, inject 0.06kg / m through steam nozzle 5 in the phase change chamber 3 (Fume) saturated steam at atmospheric pressure. After measurement, after the water-vapor phase transition is applied in the wet desulfurization process, the number concentration of fine particles in the flue gas passing through the outlet of the wire mesh demister can be reduced from 4.02×10 7 Pieces / cm 3 down to 1.65×10 7 Pieces / cm 3 , adding steam can increase the removal e...

Embodiment 2

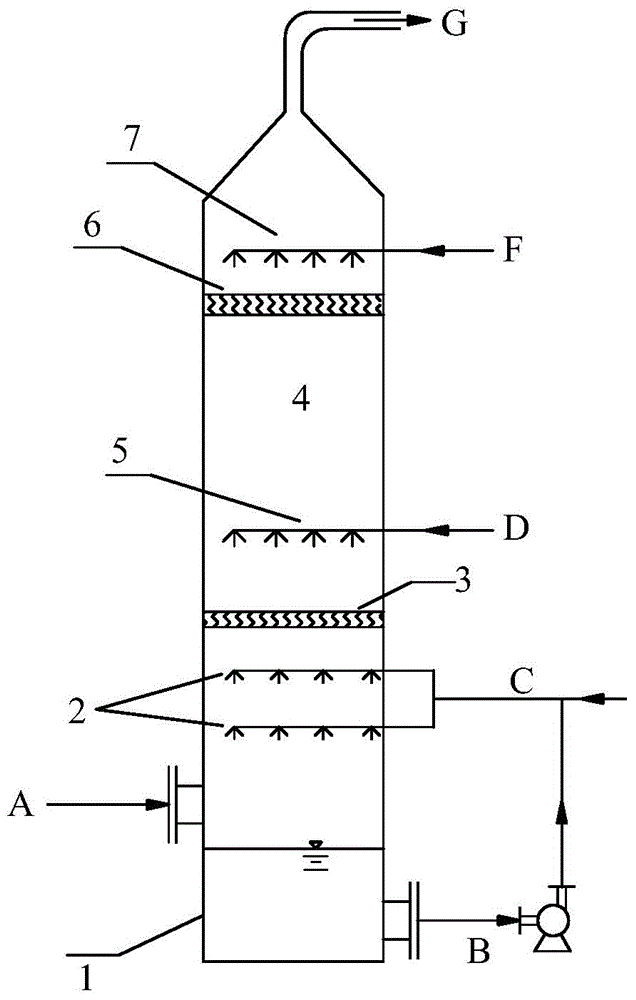

[0033] like image 3 As shown, the difference from Example 1 is that the water-vapor phase change chamber 4 is not separately set after the wet desulfurization tower 1, but the height of the wet desulfurization tower 1 is appropriately increased, so that the space above the wet desulfurization tower demister 3 As the water-vapor phase change chamber 4, and inject an appropriate amount of normal pressure saturated water vapor, a high-efficiency wire mesh demister is arranged at the outlet of the water-vapor phase change chamber 4 at the top of the tower, and the rest are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com