Coal pyrolysis gas elemental mercury sampling system

A sampling system and elemental mercury technology, applied in the direction of sampling devices, etc., can solve the problems of inaccurate reflection of mercury concentration, complex sampling site operation, harsh environmental requirements, etc., and achieve good results, convenient packaging and transportation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

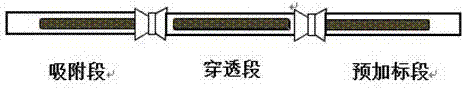

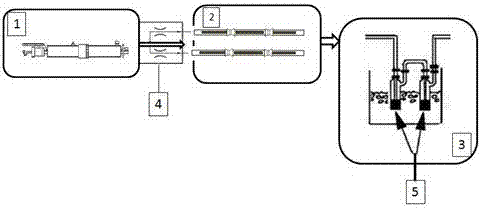

[0014] The coal pyrolysis gas elemental mercury sampling system includes a sampling gun, an adsorption tube, an adsorbent, and a solution absorption tank; the sampling gun is connected to the adsorption tube, and the docking position of the adsorption tube and the sampling gun is provided with an internal and external thread or a frosted interface that cooperates with each other. The inlet of the adsorption tube is equipped with quartz wool, the adsorbent is located inside the adsorption tube, and the solution absorption pool is located at the outlet of the adsorption tube; the adsorption tube is made of quartz tube, the adsorption tube is a variable diameter tube, and the diameter of the inlet connecting the sampling gun and the adsorption tube becomes smaller gradually. The inner diameter gradually changes from 10mm to 4mm.

[0015] as attached figure 1 As shown, the adsorption tube is divided into three sections, the first section is an adsorption section with an inner diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com