Preparation method and applications of gaseous mercury adsorbent

A gaseous mercury and adsorbent technology, applied in the field of gaseous mercury adsorbents, can solve problems such as impact, high material cost, increase mercury emission nodes and subsequent control difficulties, and achieve high mercury removal efficiency, high mercury removal efficiency, The effect of excellent sulfur resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of preparation method of gaseous mercury sorbent of the present invention comprises the following steps:

[0039] (1) Take 0.05 mol of copper nitrate and add it to 30 mL of deionized water, stir until it is completely dissolved; then take 0.2 mol of thiourea, add it to the prepared copper nitrate solution, and ultrasonicate for 15 minutes to ensure the formation of uniform copper-sulfur Urea complex solution;

[0040] (2) Take 15mL of sulfuric acid matured activated carbon (prepared by the method of Comparative Example 1), add it to the prepared 30mL copper thiourea complex solution, stir and impregnate for 20min, the stirring speed is 500r / min, and the impregnation temperature is 25°C , impregnated, filtered, and dried to obtain a gaseous mercury adsorbent (activated carbon after sulfuric acid aging + copper thiourea complex impregnation).

Embodiment 2

[0042] A kind of preparation method of gaseous mercury sorbent of the present invention comprises the following steps:

[0043] (1) Take 0.05 mol of ferric nitrate and add it to 30 mL of deionized water, stir until it is completely dissolved; then take 0.2 mol of thiourea, add it to the prepared ferric nitrate solution, and ultrasonicate for 15 minutes to ensure the formation of uniform iron-sulfur Urea complex solution;

[0044] (2) Get 15mL of sulfuric acid-cured activated carbon (prepared by the method of Comparative Example 1), add it to the prepared 30mL iron-thiourea complex solution and stir and impregnate for 20min, the stirring speed is 500r / min, and the impregnation temperature is After impregnation at 25°C, filter and dry to obtain a gaseous mercury adsorbent (activated carbon after sulfuric acid aging + iron-thiourea complex impregnation).

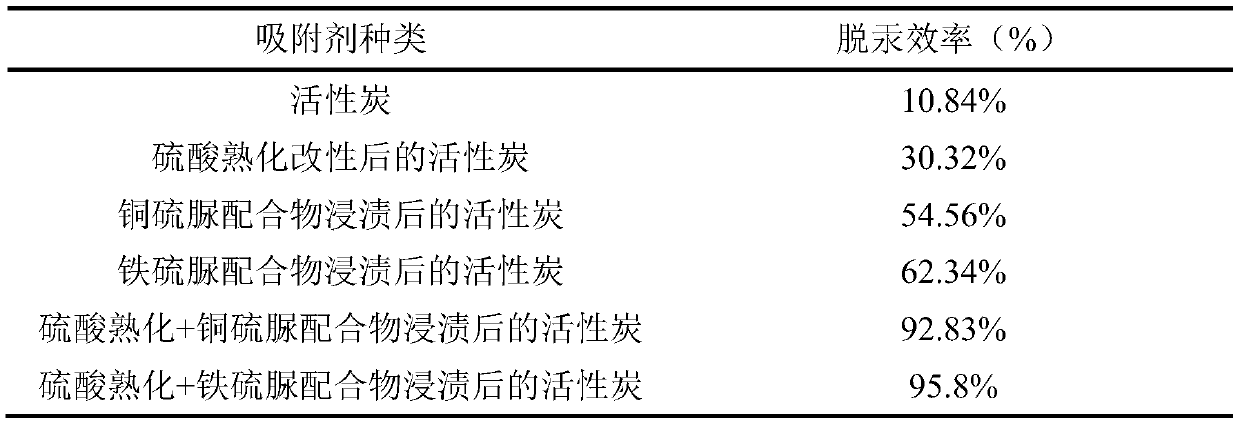

[0045] The pure activated carbon adsorbent, the adsorbent samples prepared in Comparative Examples 1-3 and Examples 1-3 were...

Embodiment 3

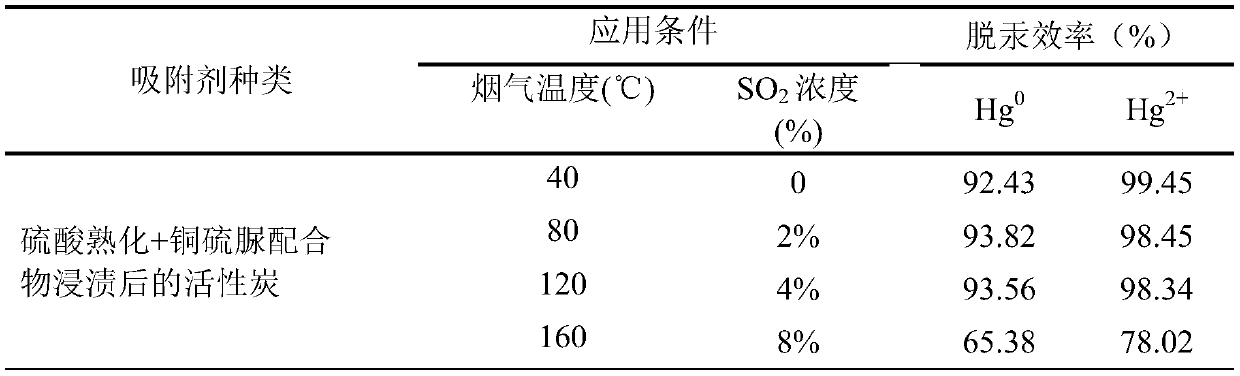

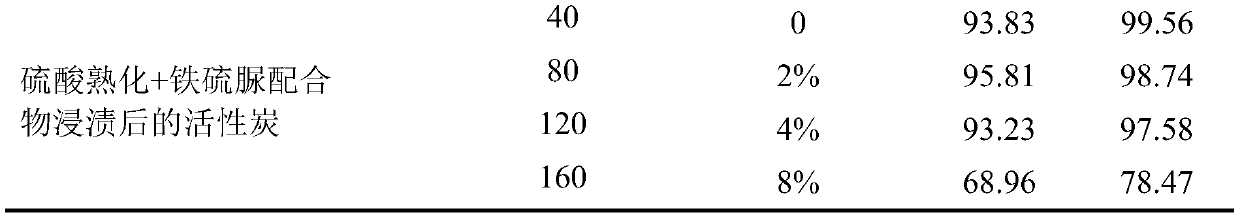

[0050] Take 0.5g of the adsorbent in Example 1 (activated carbon after sulfuric acid aging+copper thiourea complex impregnation) and the adsorbent prepared in Example 2 (activated carbon after sulfuric acid aging+iron thiourea complex impregnation), fix the flue gas Middle O 2 The concentration is 10v%, the flue gas flow rate is 600mL / min, and the concentration of gaseous mercury in the flue gas is 250μg / m 3 , to investigate the effect of adsorbent on elemental mercury (Hg 0 ) and divalent mercury (Hg 2+ ) removal effect, the results are shown in Table 2.

[0051] Table 2 The removal effect of adsorbents on elemental mercury and divalent mercury at different temperatures and concentrations of sulfur dioxide

[0052]

[0053]

[0054] It can be seen from Table 2 that when the flue gas temperature is in the range of 40-120 °C, the prepared adsorbents can achieve high-efficiency removal of mercury in the flue gas, and the mercury removal efficiency is above 95v%. As hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com