Patents

Literature

106 results about "Oxygen donor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

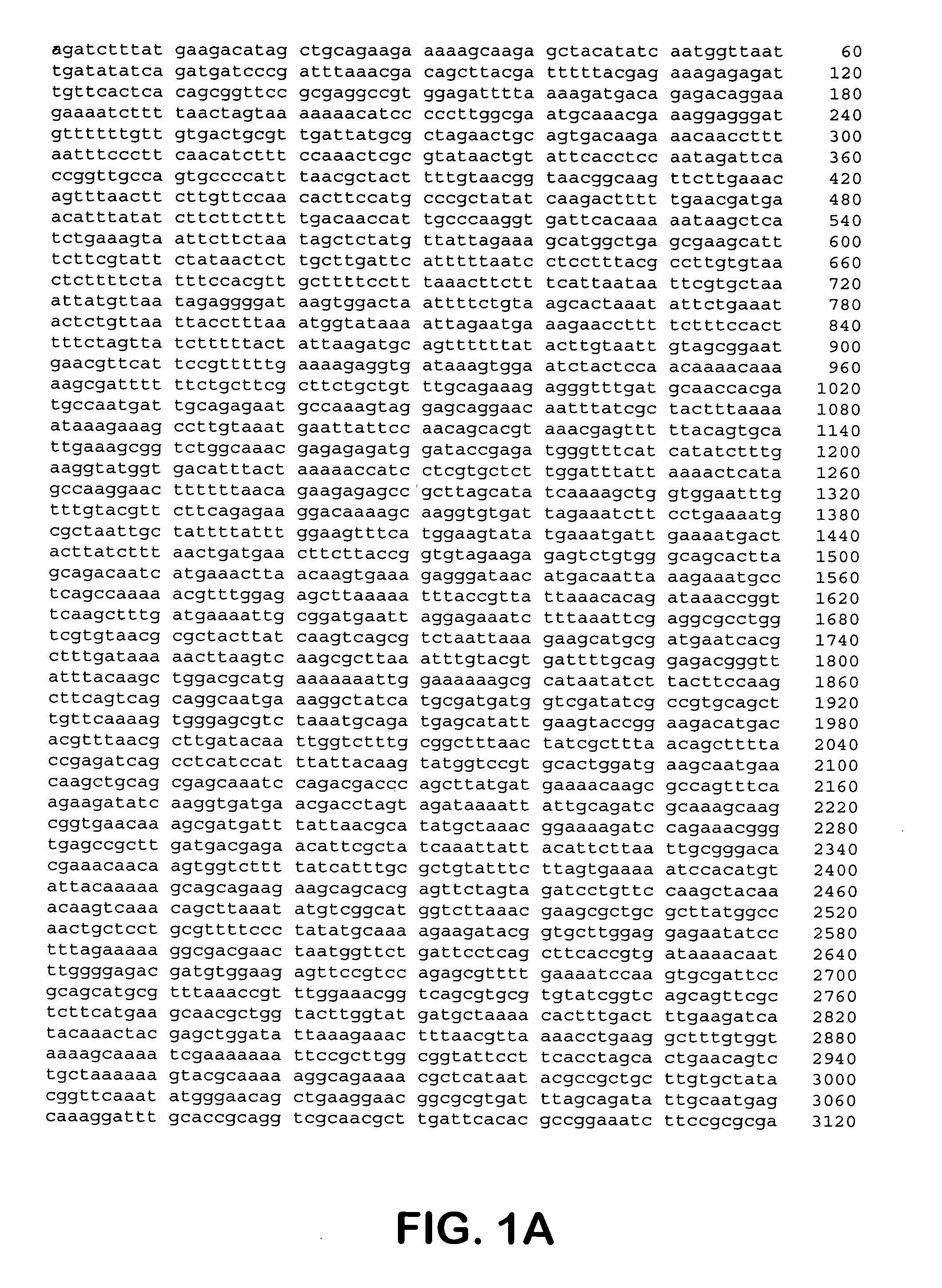

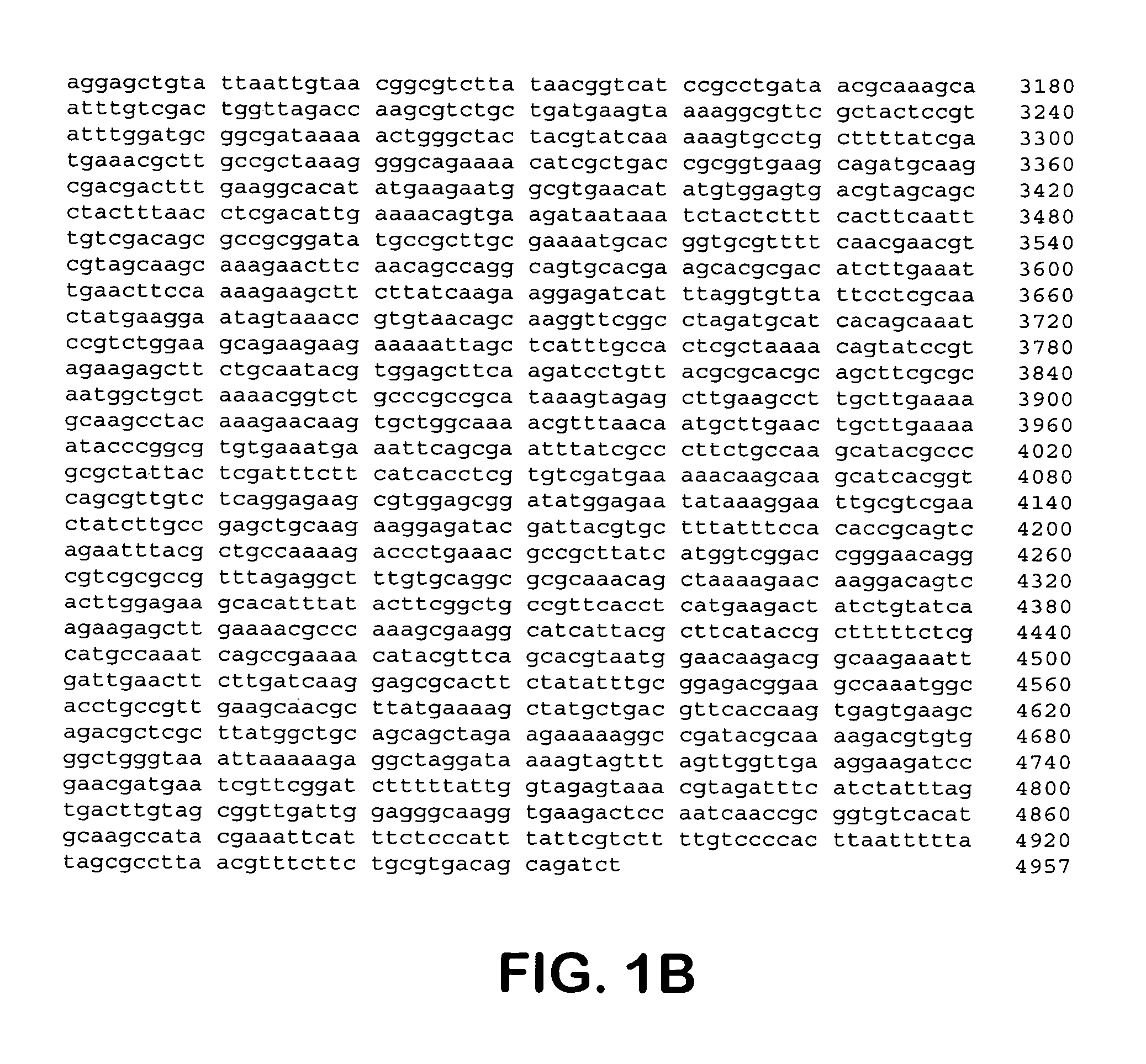

Peroxide-driven cytochrome P450 oxygenase variants

InactiveUS20050202419A1Improve abilitiesImprove thermal stabilityBacteriaSugar derivativesOxygenaseHeme

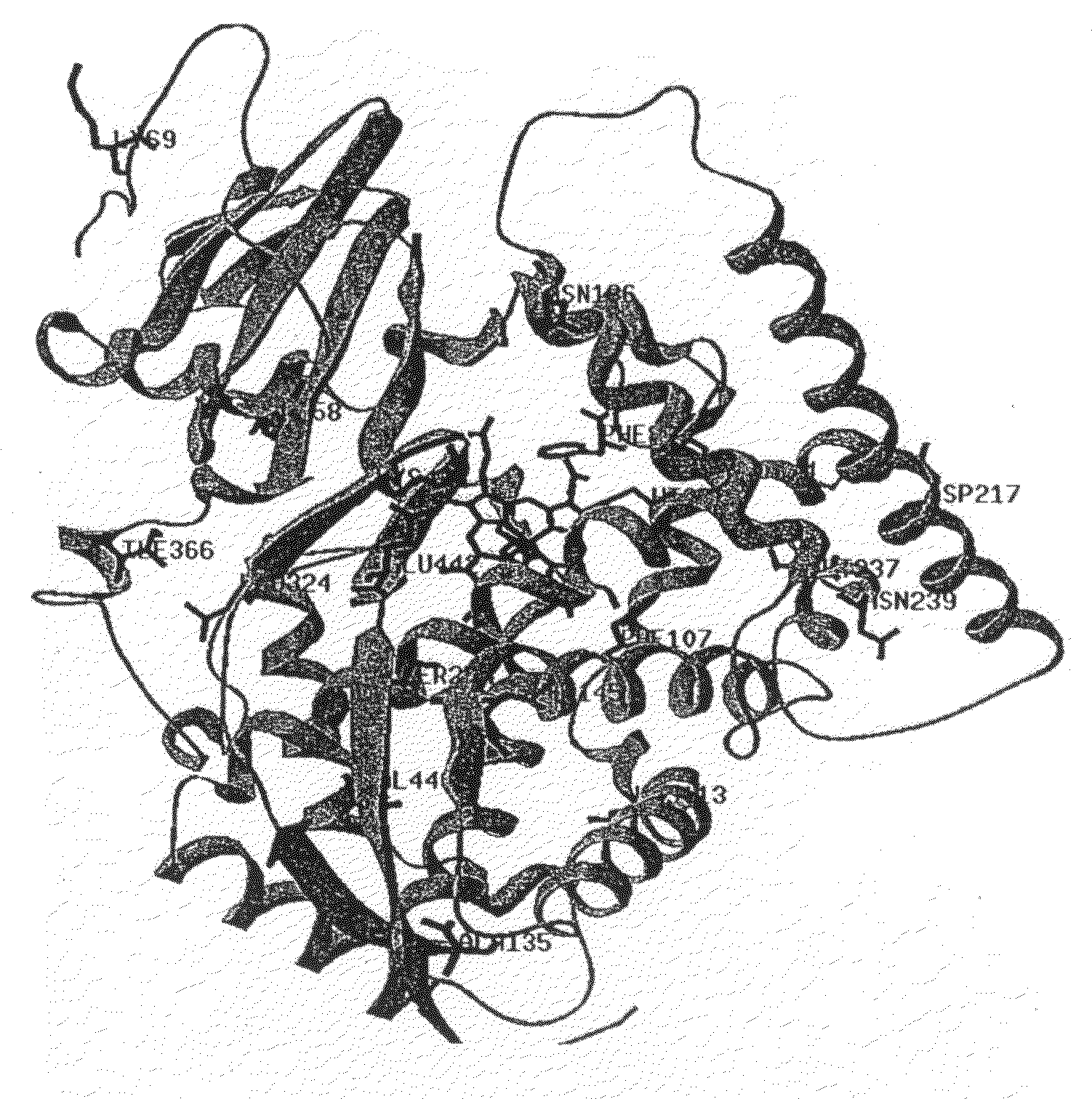

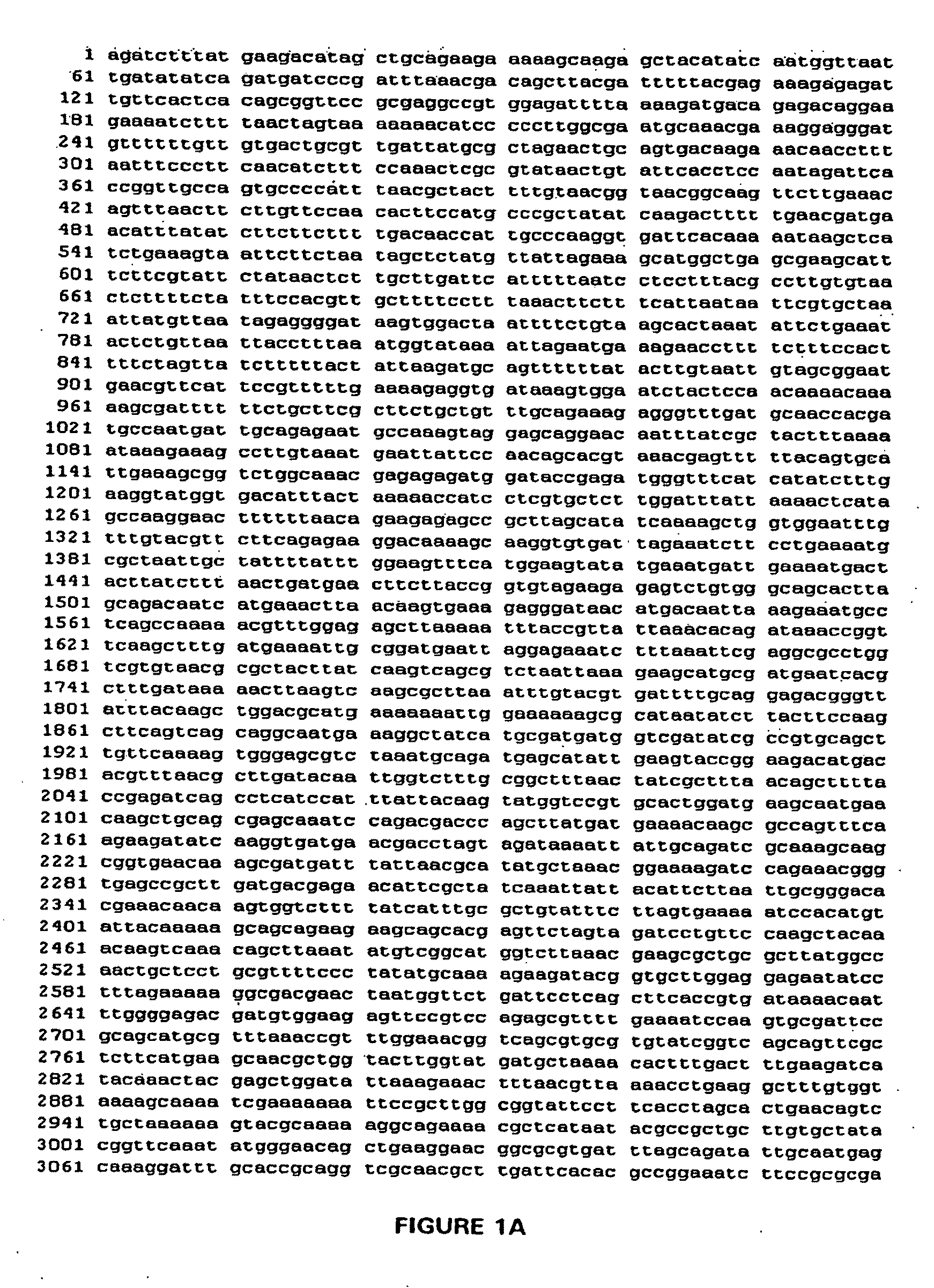

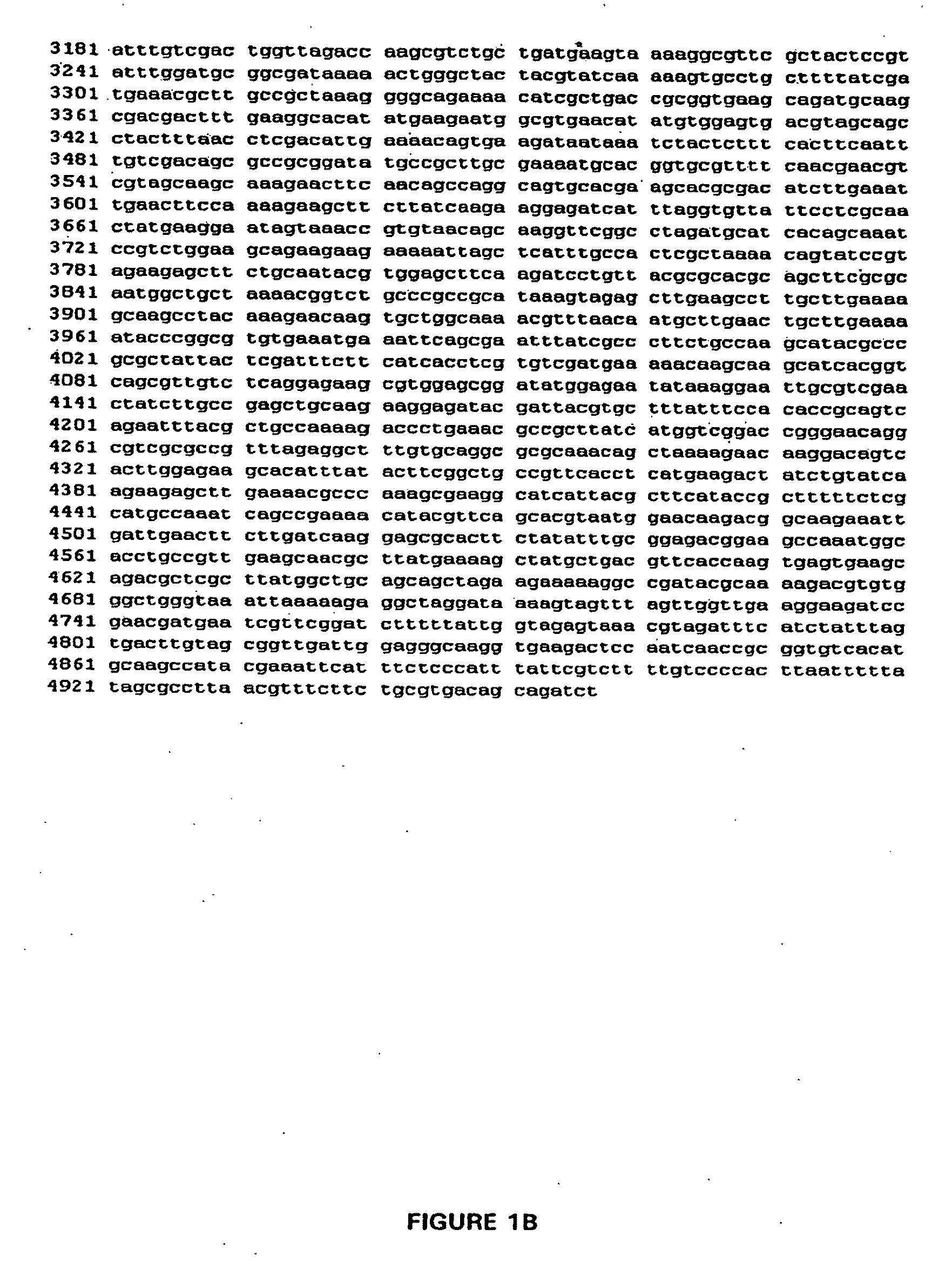

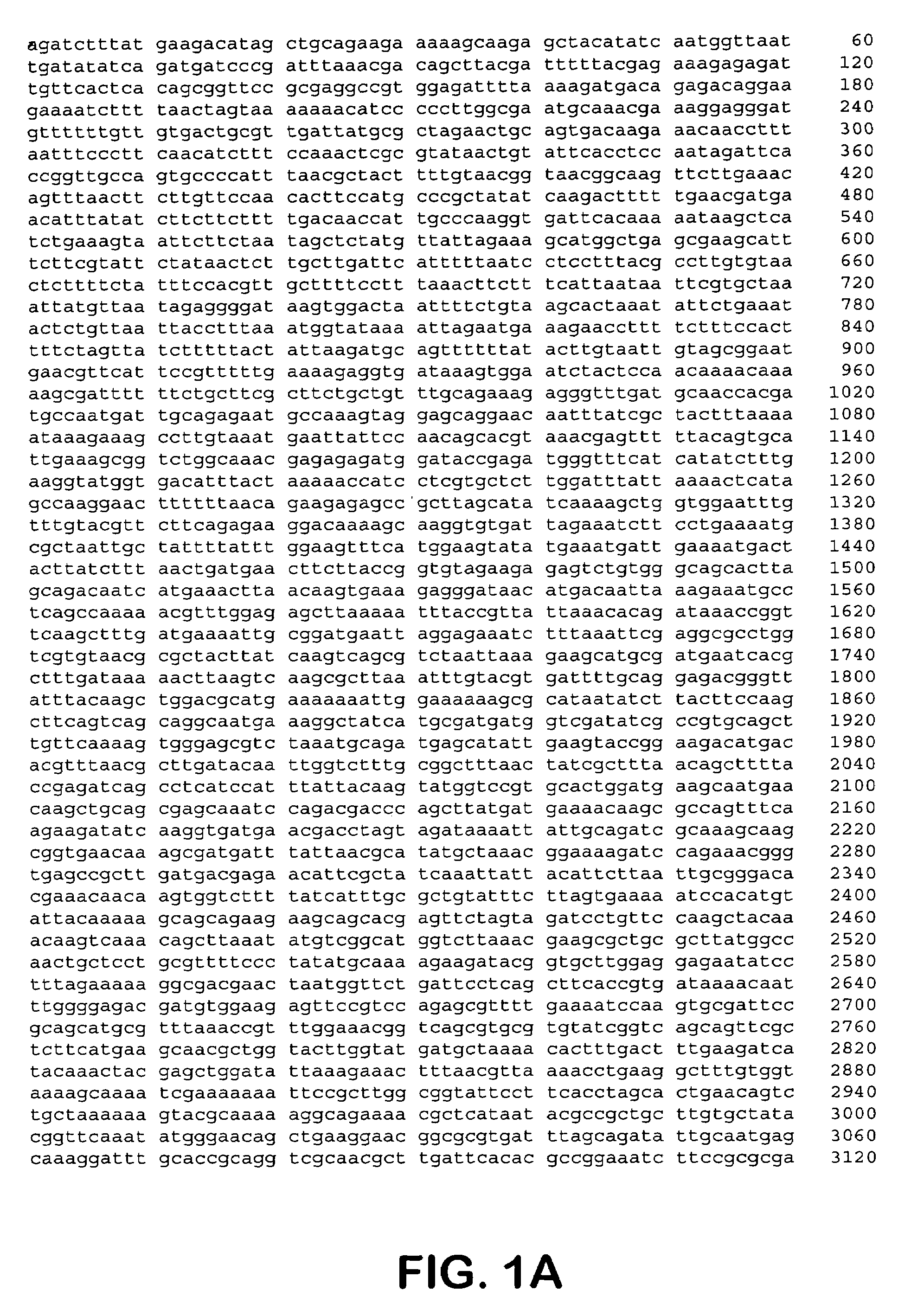

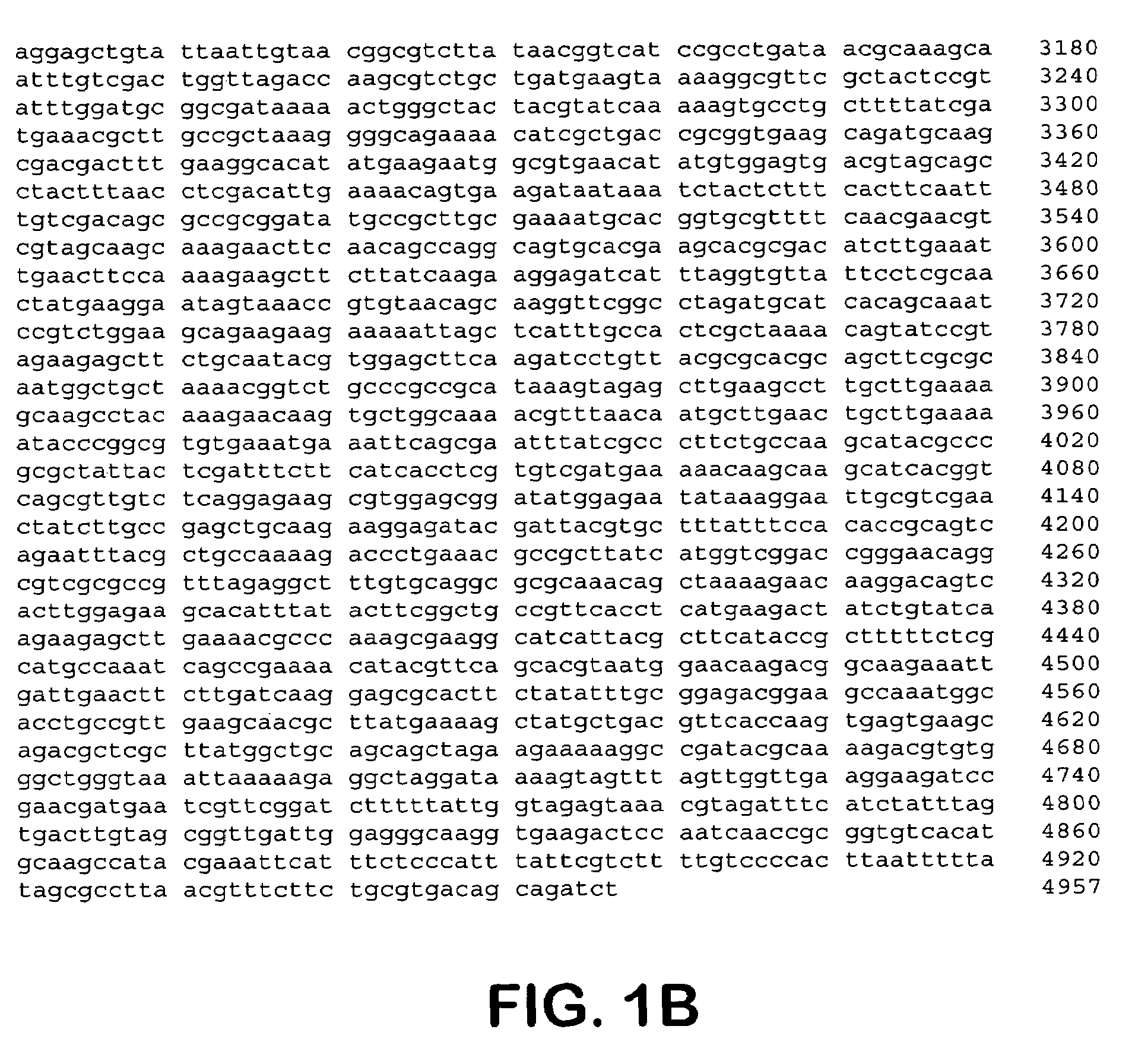

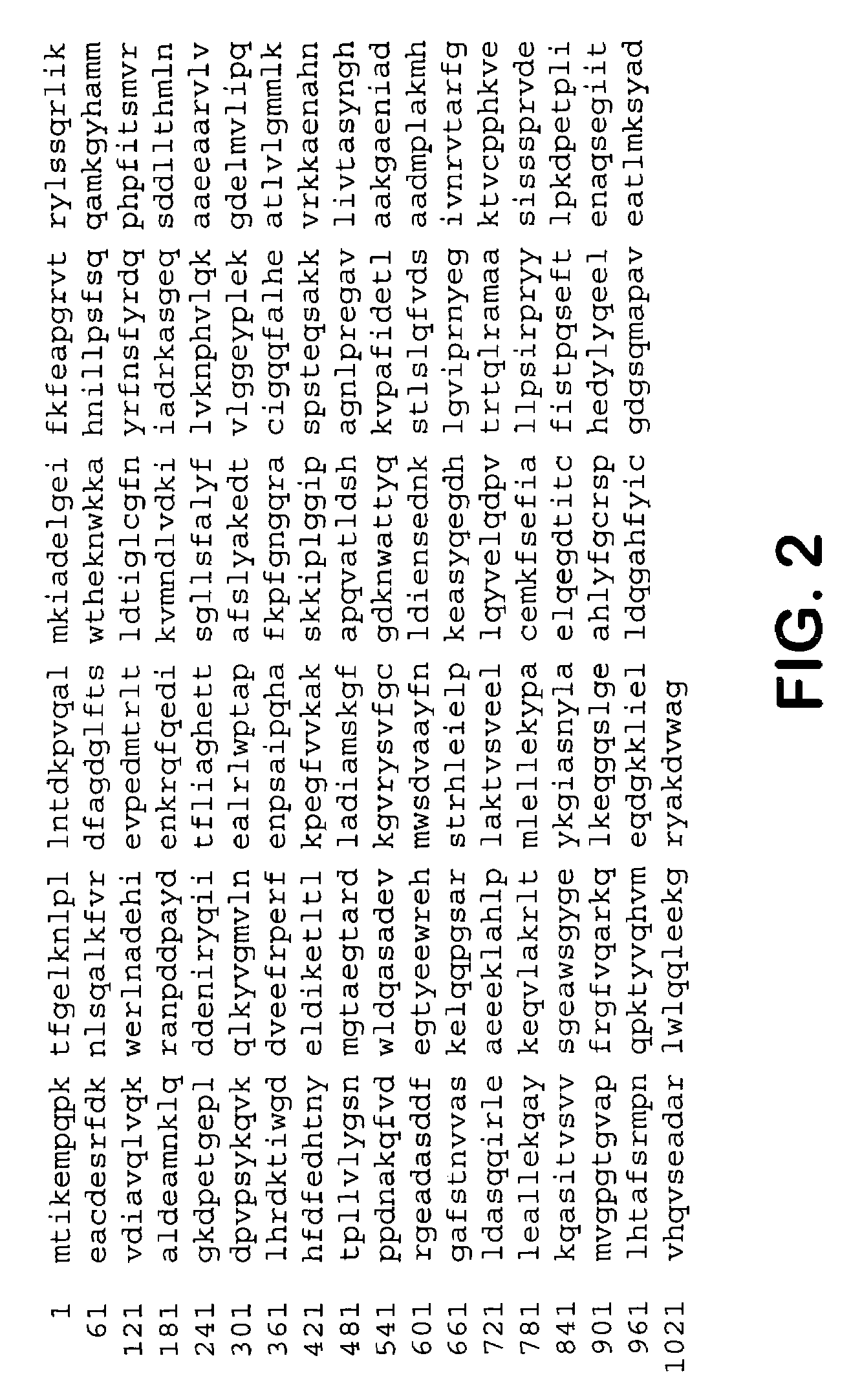

The invention relates to novel variants of cytochrome P450 oxygenases. These variants have an improved ability to use peroxide as an oxygen donor as compared to the corresponding wild-type enzyme. These variants also have an improved thermostability as compared to the cytochrome P450 BM-3 F87A mutant. Preferred variants include cytochrome P450 BM-3 heme domain mutants having I58V, F87A, H100R, F107L, A135S, M145A / V, N239H, S274T, L324I, I366V, K434E, E442K, and / or V446I amino acid substitutions.

Owner:CALIFORNIA INST OF TECH

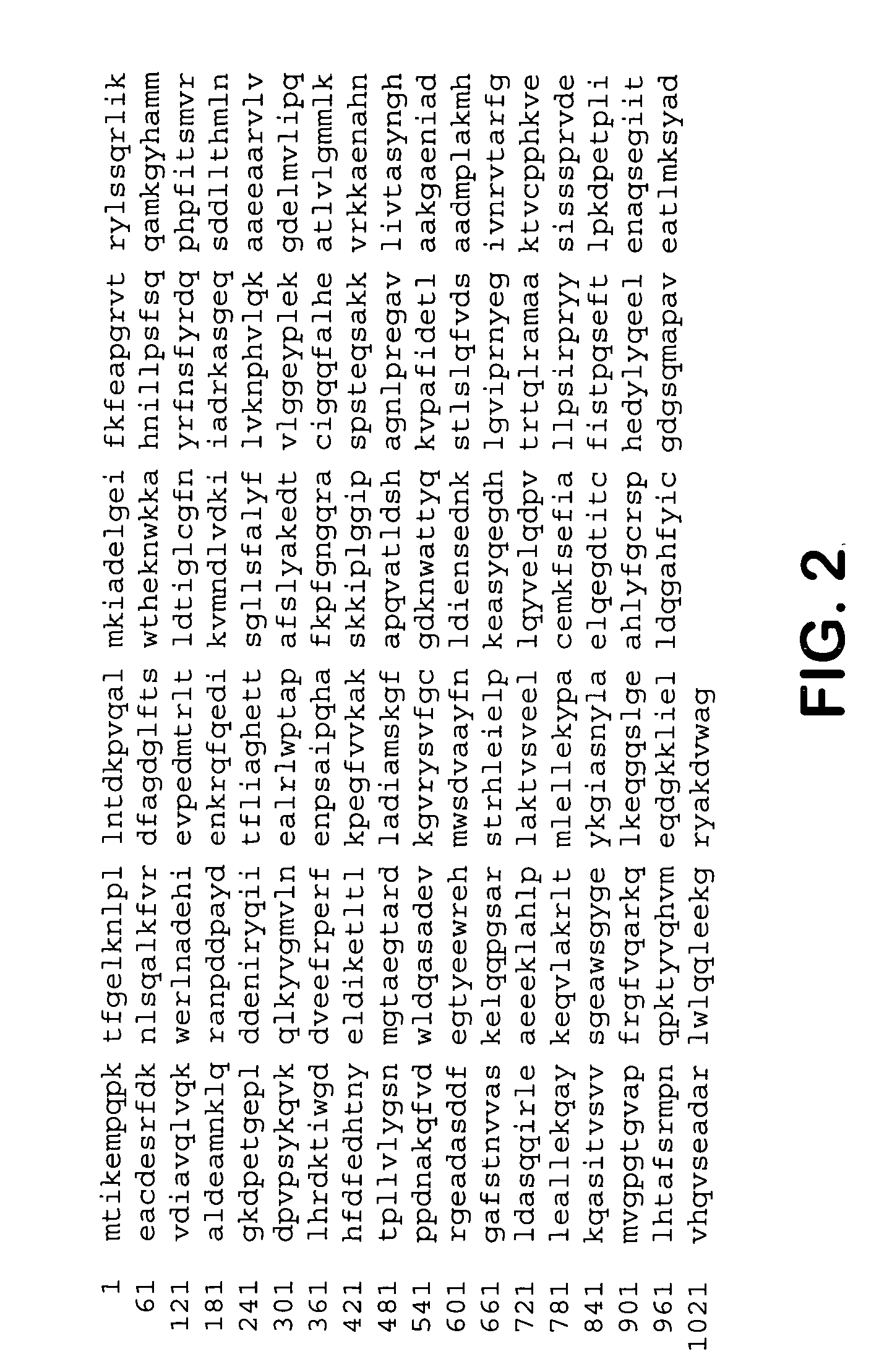

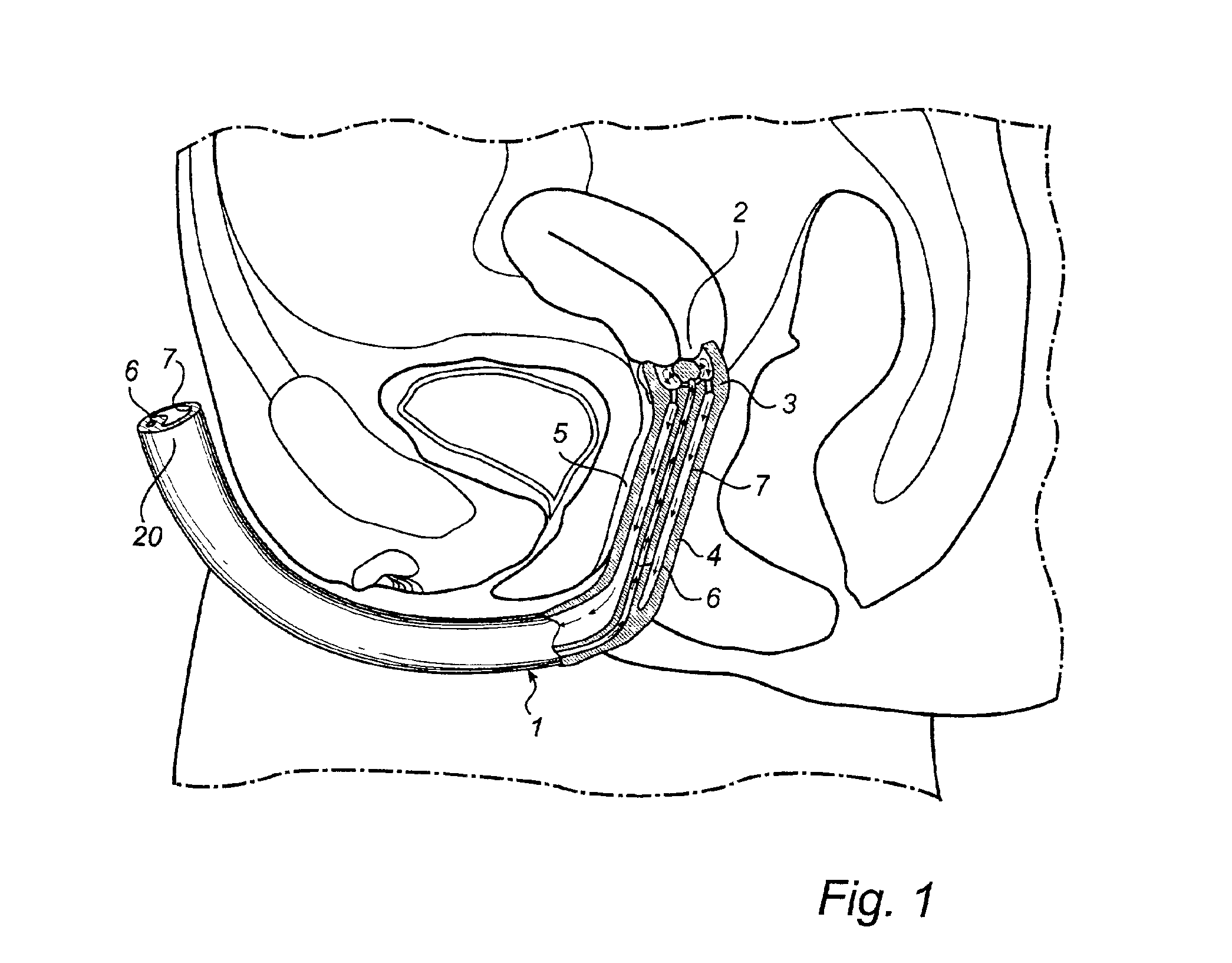

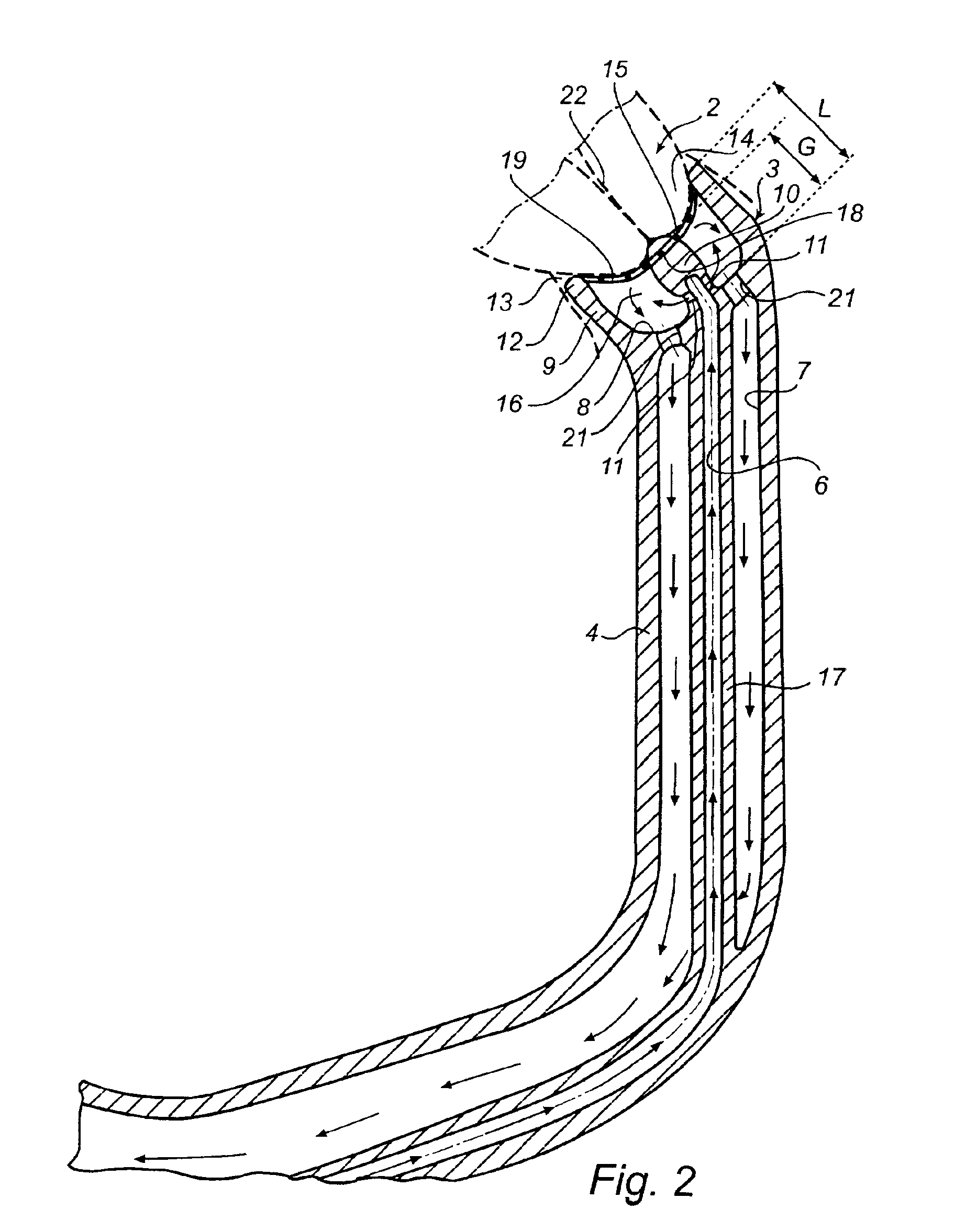

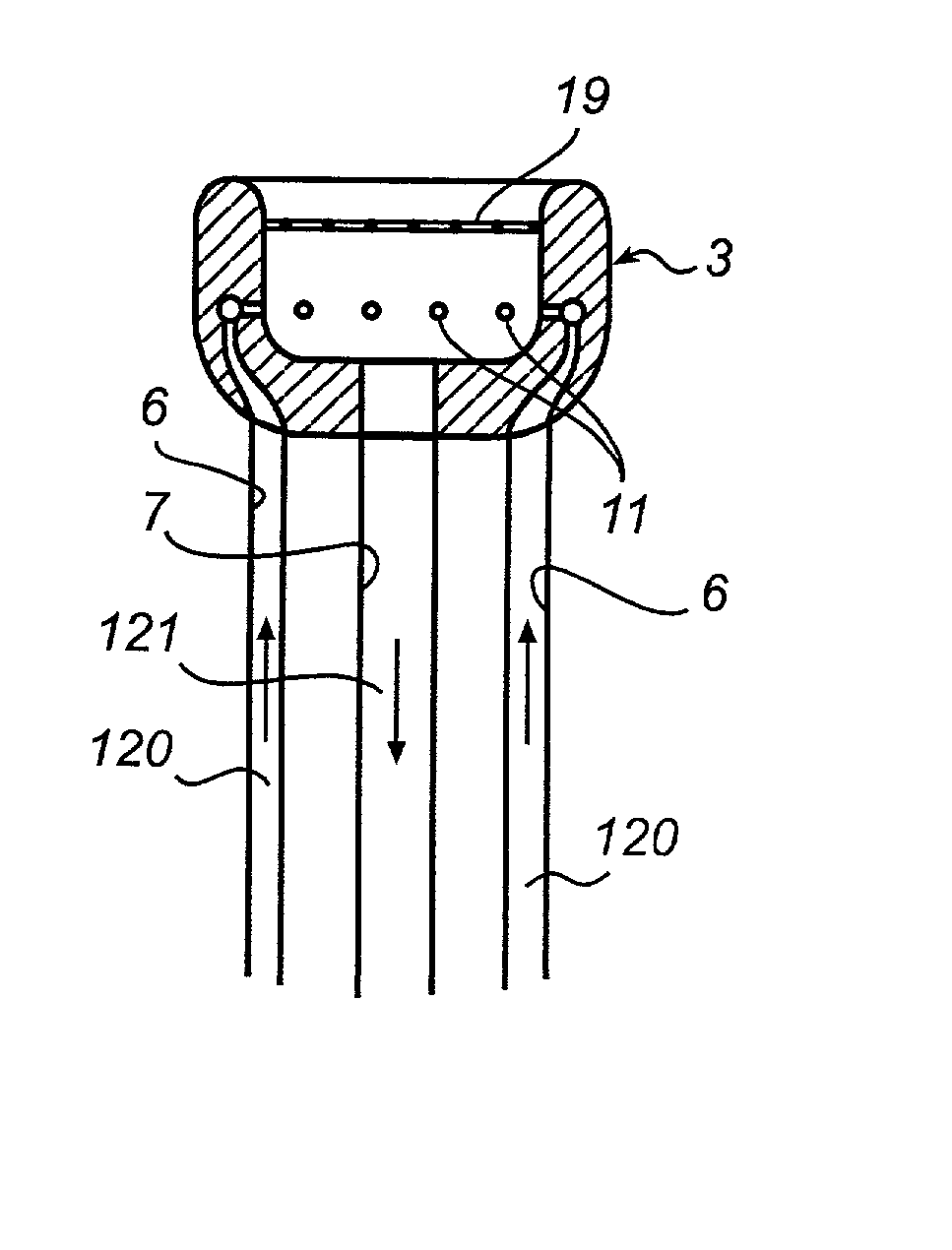

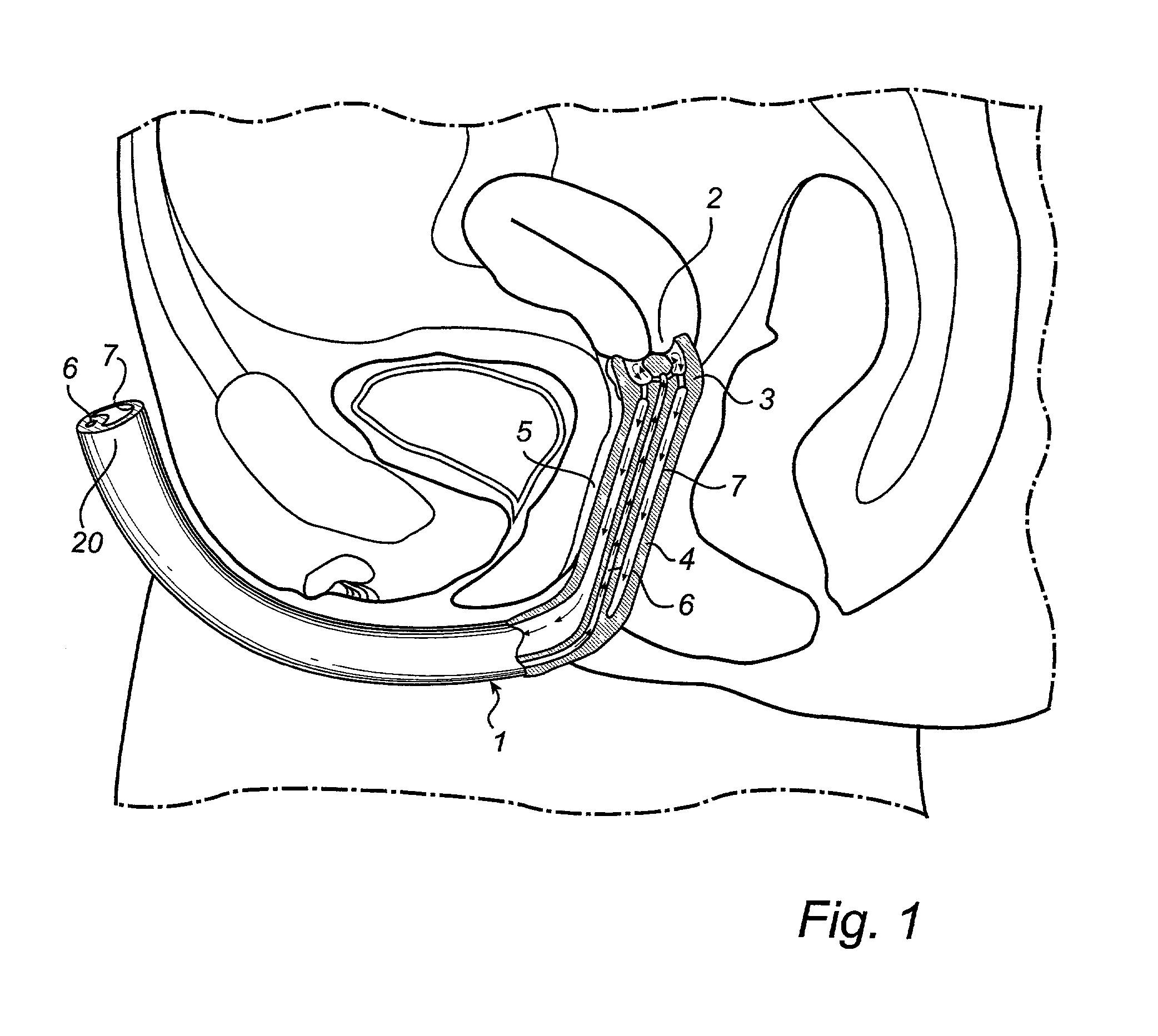

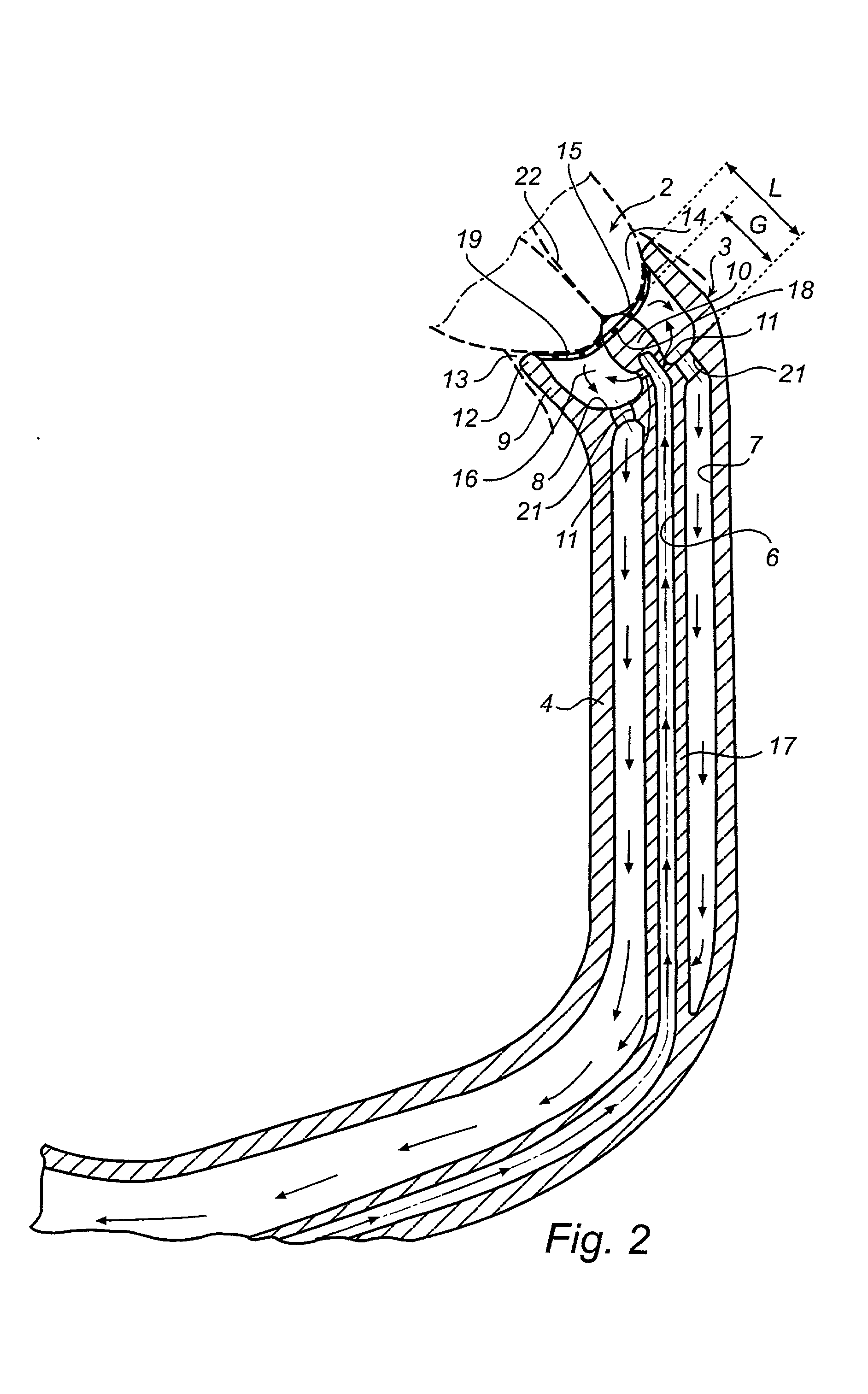

Method and device for treating inter alia the cervix

A non-invasive method for treating cells affected by at least one oncogenic virus is disclosed, comprising providing a substance comprising at least one of ozone, an ozone donor, oxygen and an oxygen donor; and subjecting the body tissue comprising the affected cells to the substance. The method is applied in the uterus cavity or uterine tubes for treating cells infected by pathologic viruses, bacteria or fungi. The device comprises a cup, having a bottom and a wall, and a shaft connected at one end to the bottom. The wall and shaft respectively extend in opposite directions from the bottom. The shaft has at least one inlet duct and at least one outlet duct. The wall has a mouth portion arranged to encircle the portio of the cervix uteri, and a chamber is defined by the bottom, wall and portio. The outlet duct(s) has at least one opening within the chamber.

Owner:SILFVER VIOLETTA

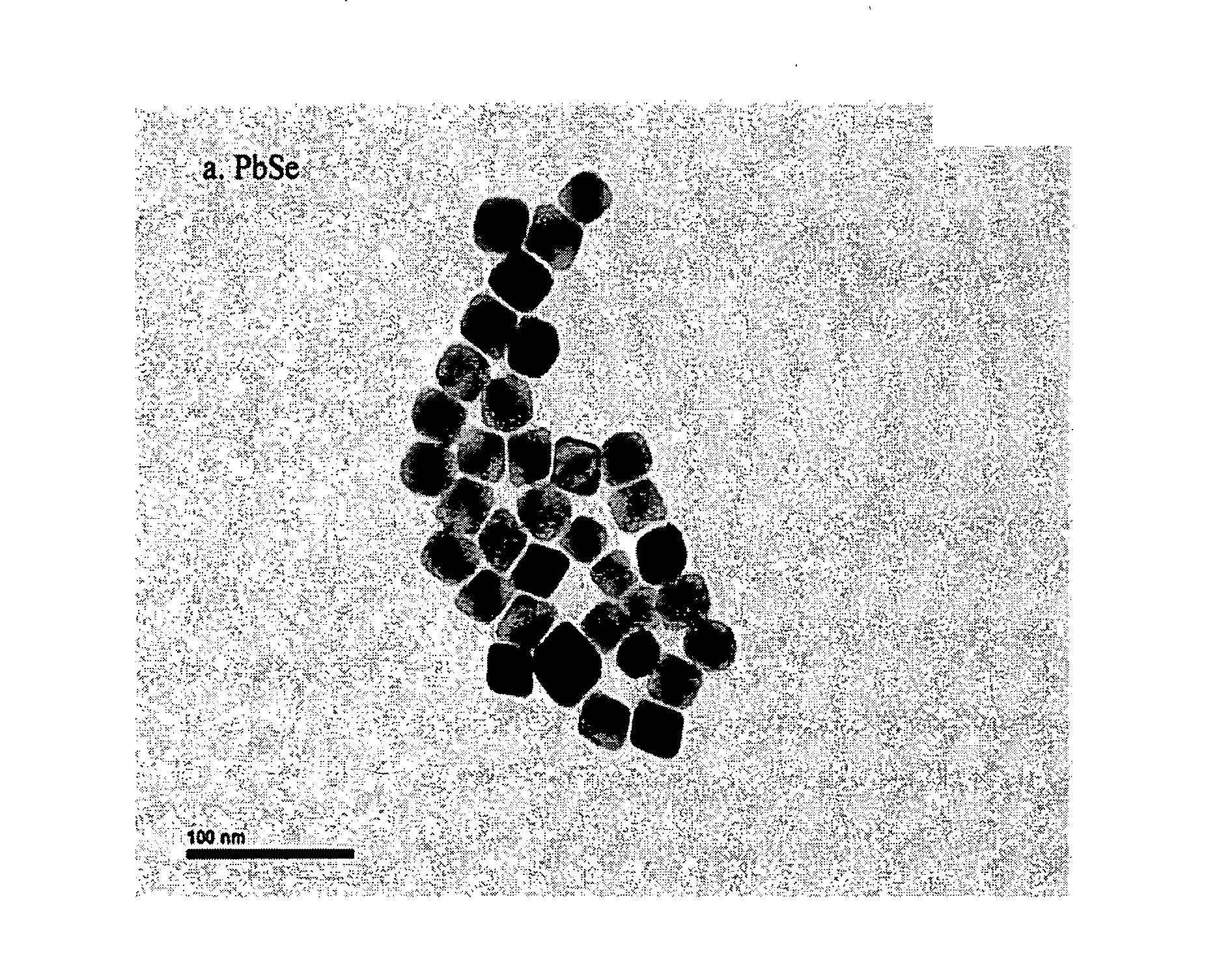

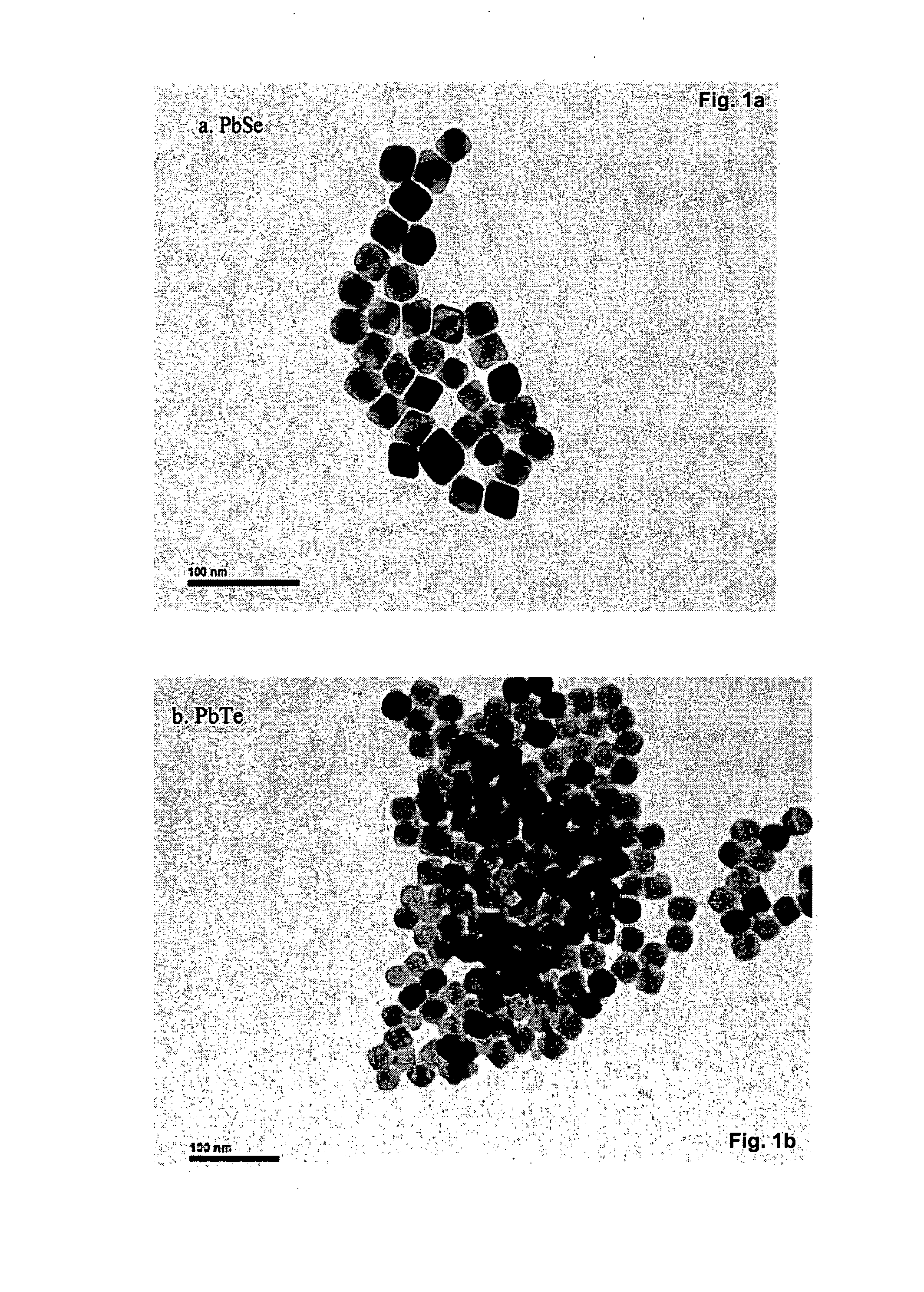

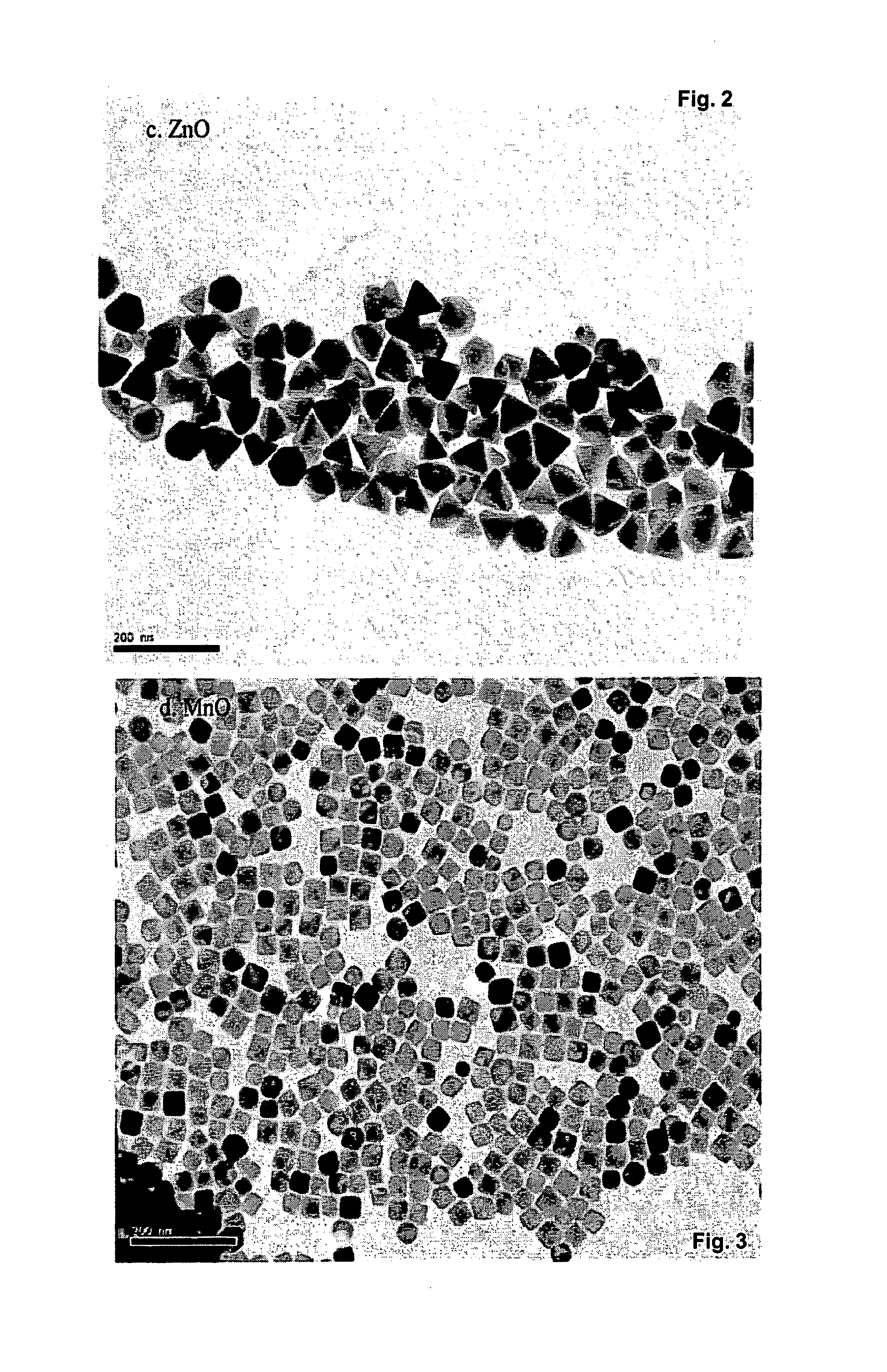

Methods of forming a nanocrystal

InactiveUS20110033368A1Low pour pointMaterial nanotechnologyFrom normal temperature solutionsBoiling pointOxygen donor

Methods of forming a nanocrystal are provided. The nanocrystal may be a binary nanocrystal of general formula M1A or of general formula M1O, a ternary nanocrystal of general formula M1M2A, of general formula M1AB or of general formula M1M2O or a quaternary nanocrystal of general formula M1M2AB. M1 is a metal of Groups II-IV, Group VII or Group VIII of the PSE. A is an element of Group VI or Group V of the PSE. O is oxygen. A homogenous reaction mixture in a non-polar solvent of low boiling point is formed, that includes a metal precursor containing the metal M1 and, where applicable M2. For an oxygen containing nanocrystal the metal precursor contains an oxygen donor. Where applicable, A is also included in the homogenous reaction mixture. The homogenous reaction mixture is under elevated pressure brought to an elevated temperature that is suitable for forming a nanocrystal.

Owner:AGENCY FOR SCI TECH & RES

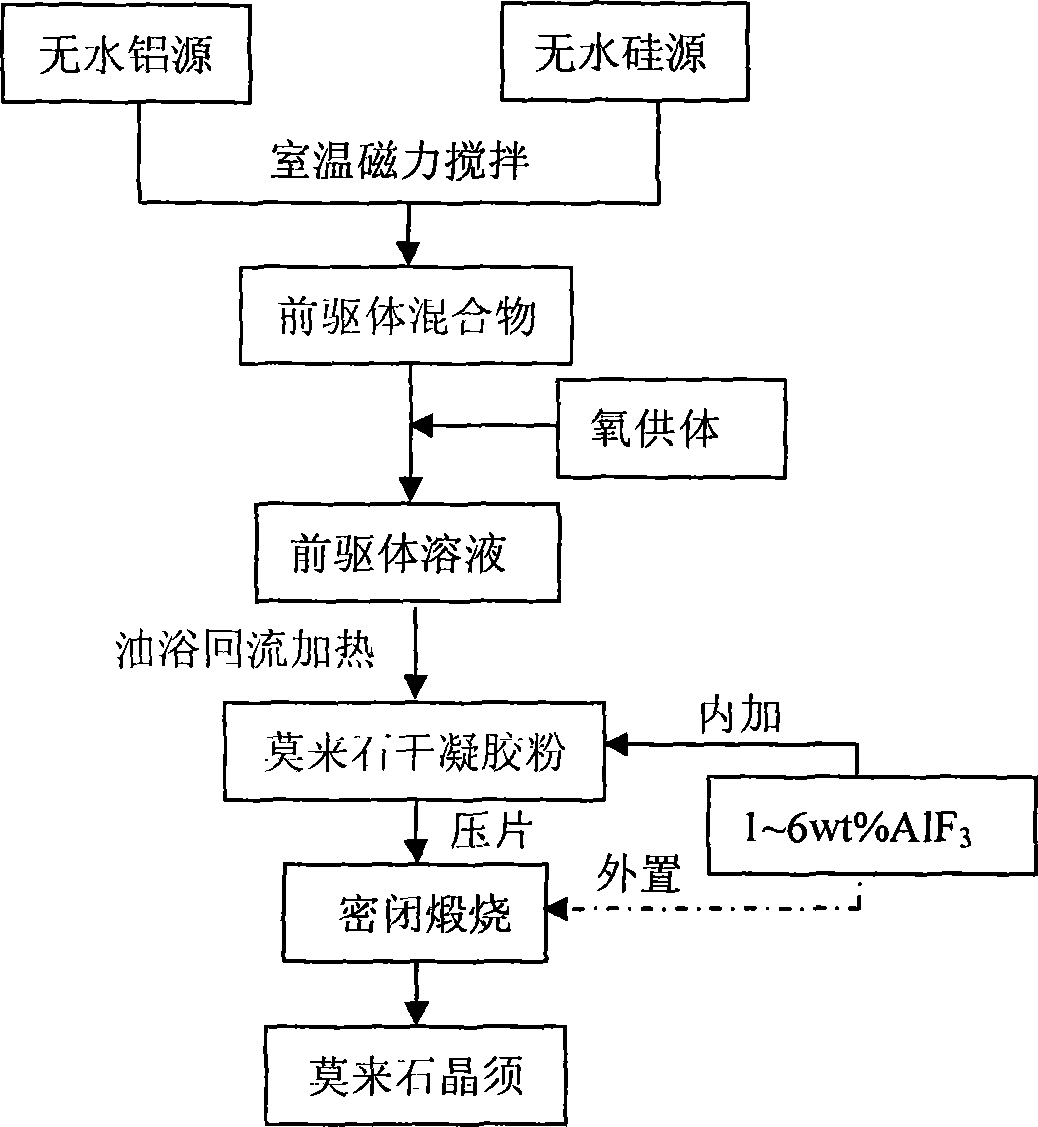

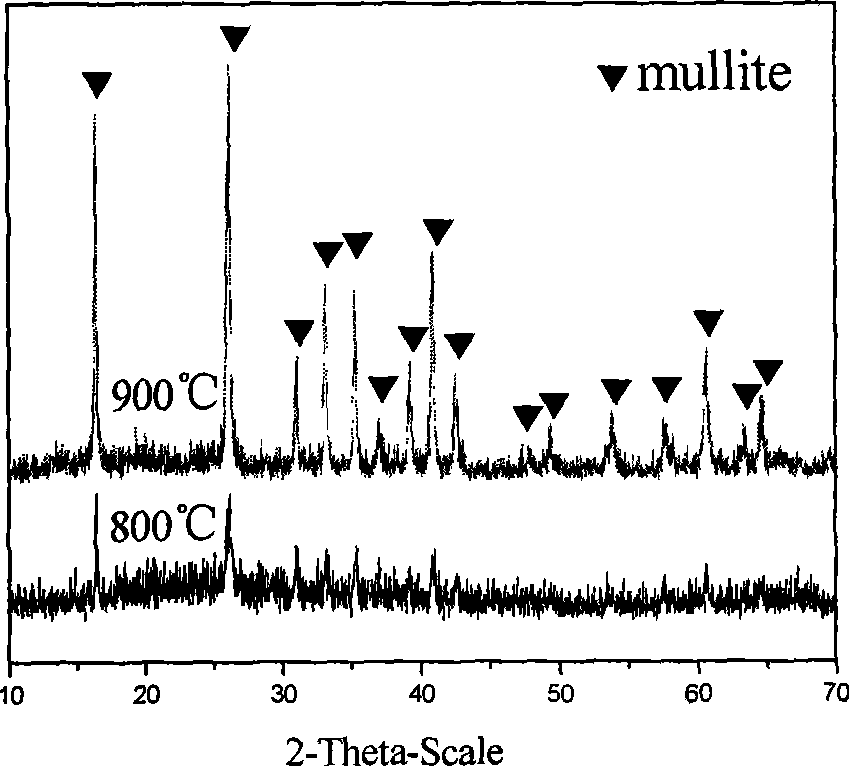

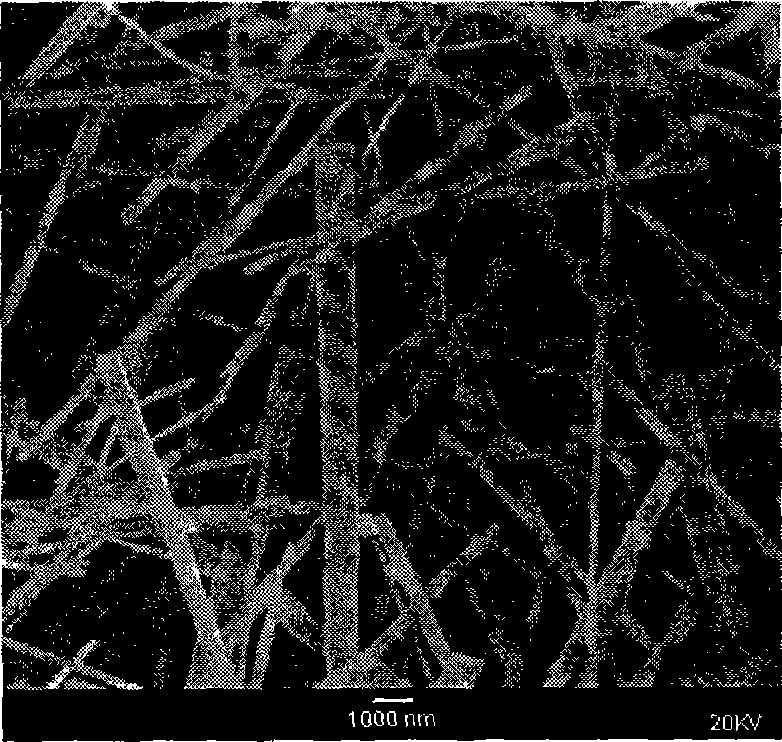

Method for preparing mullite crystal whisker by non-hydrolytic sol-gel process

InactiveCN101498049ALow preparation temperatureQuality improvementPolycrystalline material growthSingle crystal growth detailsOxygen donorSol-gel

The invention discloses a method of preparing porzite whiskers by a non-hydrolyzed sol-gel technology. The method comprises the following steps: using an anhydrous aluminum source and an anhydrous silicon source as precursors and using low-carbon alcohol or ether as an oxygen donor to prepare porzite xerogel powder; then adding a certain amount of fluoride as a whisker catalyst and calcining a closed crucible to prepare the high-purity and white porzite whiskers which have the diameter of 0.2 micron to 2 micron, a slenderness ratio up to 60 to 70 and do not comprise mingled particles. Compared with the prior art, the invention has the advantages of simple technology, convenient operation, low whisker preparation temperature and high whisker yield.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Thermostable peroxide-driven cytochrome P450 oxygenase variants and methods of use

InactiveUS20090264311A1Improve thermal stabilityImprove abilitiesSugar derivativesLibrary screeningOxygenaseHeme

The invention relates to novel variants of cytochrome P450 oxygenases. These variants have at least one mutation improving their ability to use peroxide as an oxygen donor as compared to the corresponding wild-type enzyme. The variants also have at least one mutation improving thermostability as compared to the parent enzyme or corresponding wild-type enzyme. Preferred variants include cytochrome P450 BM-3 heme domain variants having L52I, I58V, F87A, H100R, S106R, F107L, A135S, M145A / V, A184V, N239H, S274T, L324I, V340M, I366V, K434E, E442K, and / or V446I amino acid substitutions.

Owner:CALIFORNIA INST OF TECH

Polishing composition and polishing method using the same

ActiveUS20080173843A1Other chemical processesSemiconductor/solid-state device manufacturingPotassiumSingle crystal

A polishing composition contains a vanadate such as ammonium vanadate, sodium vanadate, and potassium vanadate and an oxygen donor such as hydrogen peroxide and ozone. It is preferable that the polishing composition further contains at least either one of abrasive grains and a pH adjusting agent. The polishing composition can be suitably used for polishing a silicon carbide wafer such as a hexagonal silicon carbide single crystal wafer.

Owner:FUJIMI INCORPORATED

Method for preparing mullite nanofibers by combination of non-hydrolytic sol-gel technology and electrostatic spinning technology

InactiveCN103225130ASolubleSimple manufacturing processInorganic material artificial filamentsFilament/thread formingFiberN dimethylformamide

The invention relates to a method for preparing mullite nanofibers by combination of a non-hydrolytic sol-gel technology and an electrostatic spinning technology, and belongs to the technical field of material science. The method comprises that anhydrous aluminum chloride and tetraethoxysilane as raw materials, isopropyl ether as an oxygen donor and anhydrous dichloromethane as a solvent are synthesized into mullite xerogel by the non-hydrolytic sol-gel method; anhydrous ethanol and tetrahydrofuran are mixed into a mixed solution A; the mullite xerogel is dissolved in the mixed solution A so that a mixed solution B is obtained; polyvinylpyrrolidone (PVP) and the mixed solution B are mixed by stirring; a less amount of N-N-dimethylformamide is dropwisely added into the mixture obtained by the previous step so that a spinning precursor is obtained; the spinning precursor is prepared into mullite xerogel / PVP composite fibers by an electrostatic spinning technology; and the mullite xerogel / PVP composite fibers are calcined at a temperature of 900 to 1200 DEG C and then are subjected to heat preservation for 0.5 to 5h to form the mullite nanofibers. The method has the advantages of simple processes, easy control and low preparation cost.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Peroxide-driven cytochrome P450 oxygenase variants

The invention relates to novel variants of cytochrome P450 oxygenases. These variants have an improved ability to use peroxide as an oxygen donor as compared to the corresponding wild-type enzyme. These variants also have an improved thermostability as compared to the cytochrome P450 BM-3 F87A mutant. Preferred variants include cytochrome P450 BM-3 heme domain mutants having I58V, F87A, H100R, F107L, A135S, M145A / V, N239H, S274T, L324I, I366V, K434E, E442K, and / or V446I amino acid substitutions.

Owner:CALIFORNIA INST OF TECH

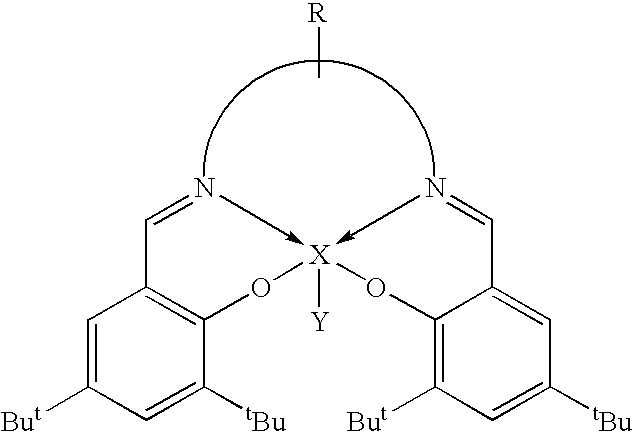

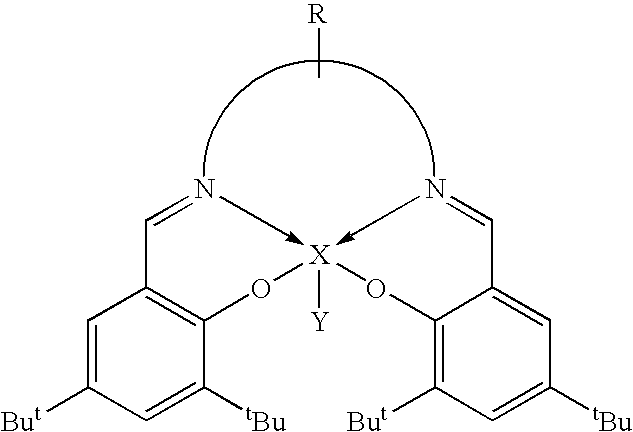

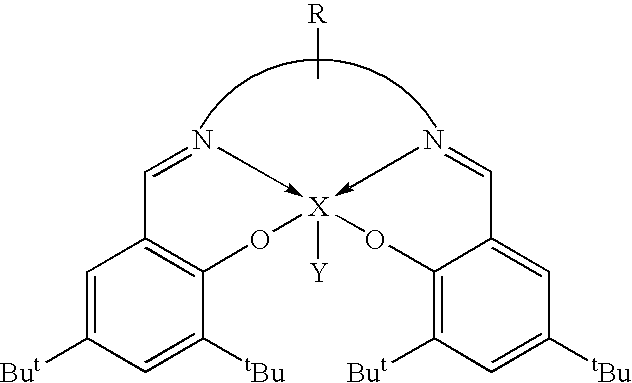

Cleavage of phosphate ester bonds by use of novel group 13 chelate compounds

InactiveUS7105703B1Organic-compounds/hydrides/coordination-complexes catalystsCobalt organic compoundsPhosphateOxygen donor

A novel chemical compound has a general formula (LX)nY wherein X is selected from a group consisting of a group 13 element other than boron, Y is selected from a group consisting of a halide, a chlorate, a sulfate and a nitrate and L is a chelating ligand containing two nitrogen and two oxygen donor groups where n=1 or 2.

Owner:UNIV OF KENTUCKY RES FOUND

Oxygen-donor and catalytic coatings of metal oxides and metals

InactiveUS20070015002A1Reducing fuel penaltyReducing the fuel penaltyDispersed particle separationCatalyst activation/preparationCoated surfaceCarbonization

A method to fabricate thin, penetrating coatings of metal oxides with oxygen storage capability is disclosed. The application of these coating in diesel exhaust particulate oxidation, carbonization prevention in ethylene cracking pipes etc. is also disclosed. In this method, the use of thin, penetrating coatings of catalytic metals decreases the oxidation temperature of carbon in contact with or near the coated surfaces. Finally, the invention describes a method to prepare a better bonding surface for laying down catalysts through traditional calcification slurry methods, by pre-coating the surface with a thin, penetrating coating of metal oxide.

Owner:C 3 INTL +1

Method and device for treating inter alia the cervix

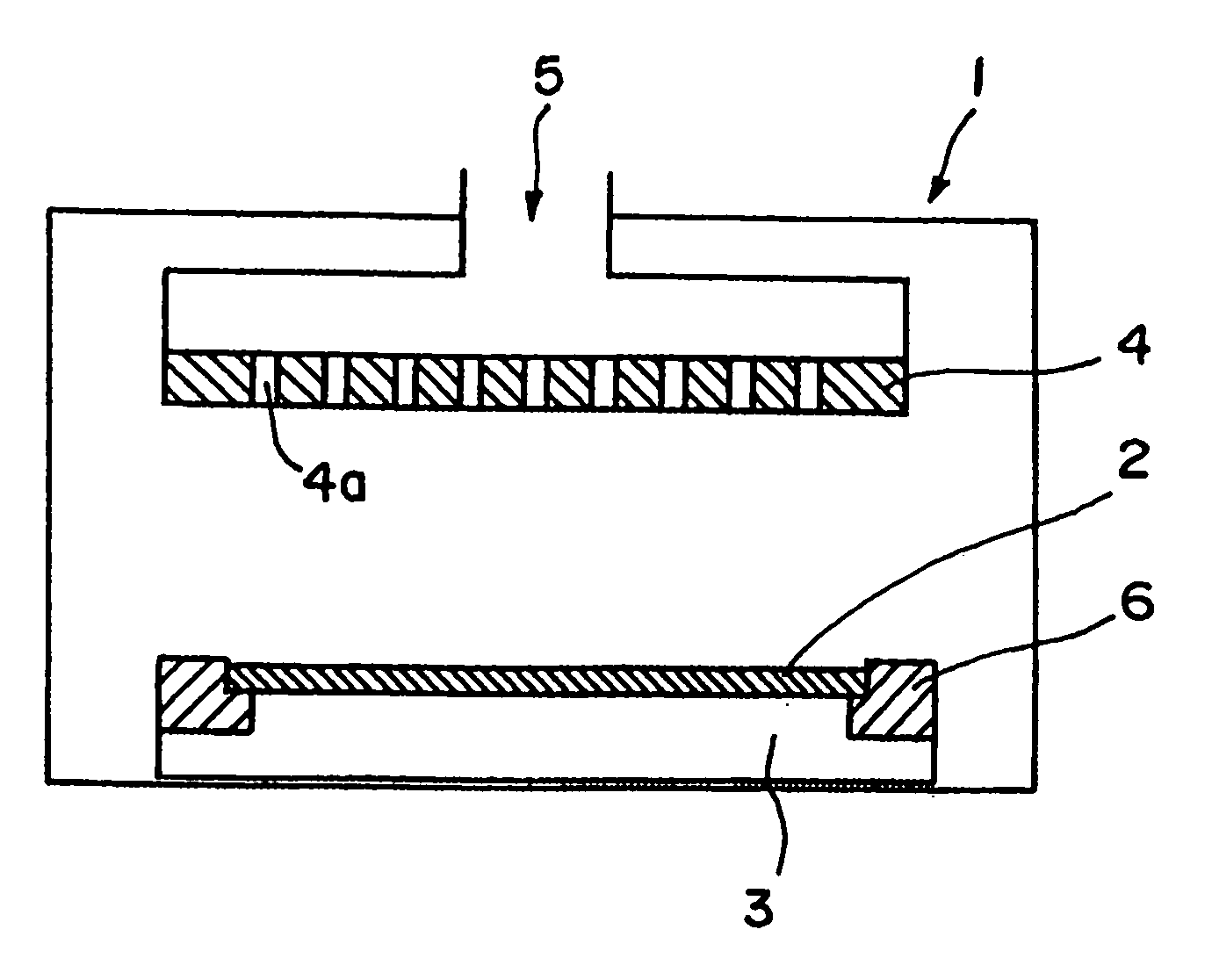

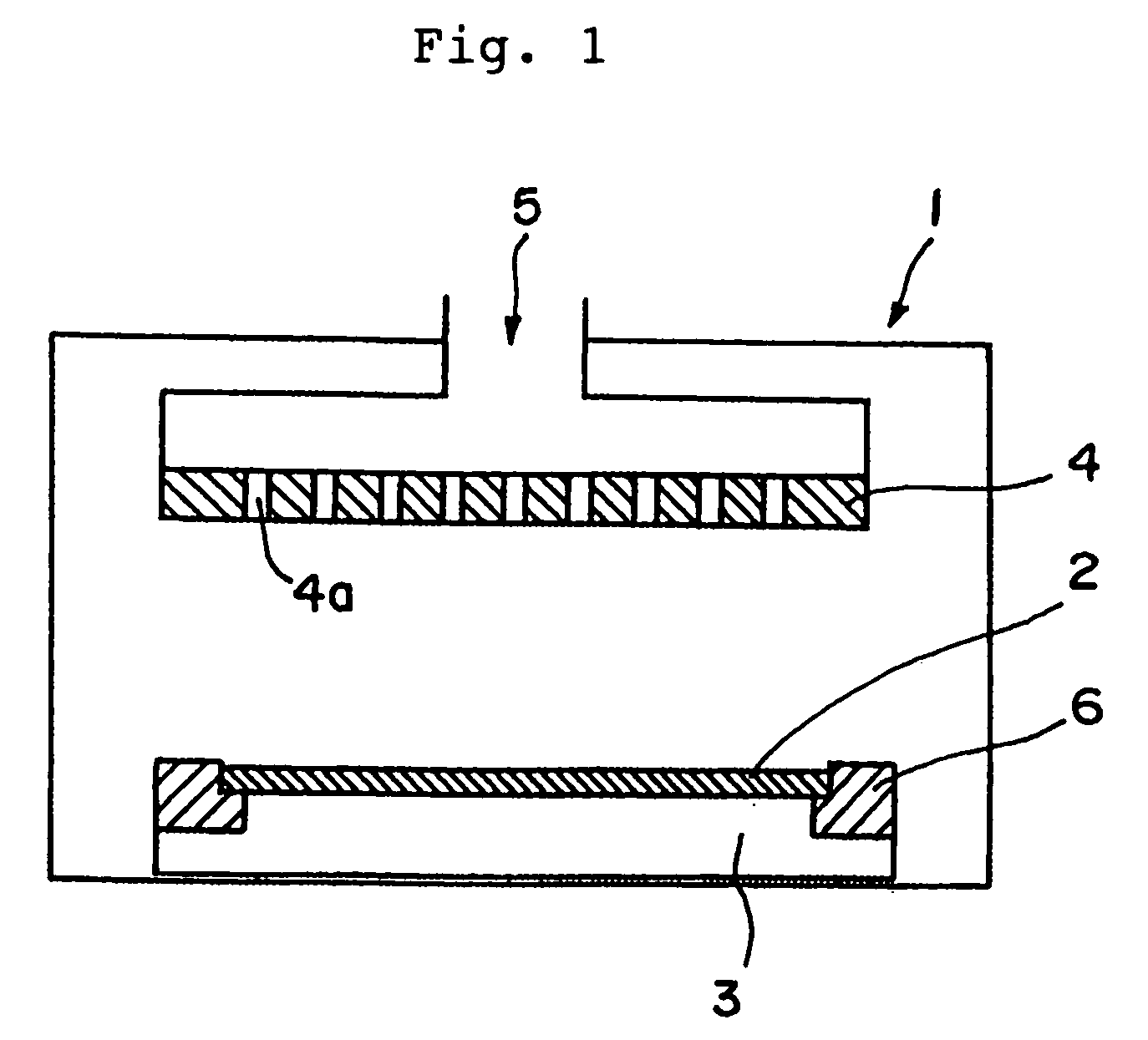

This invention relates to a non-invasive method for treating cells affected by at least one oncogenic virus, comprising the steps of providing a substance comprising at least one of ozone, an ozone donor, oxygen and an oxygen donor; and subjecting an area of body tissue comprising the affected cells to the substance. Further the invention relates to the non-invasive method applied in uterus cavity and uterine tubes for treating cells infected by at least one of pathologic viruses, bacteria and fungi. Further a device for performing the method at the cervix uteri is provided by this invention. The device comprises a cup, having a bottom and a wall, and a shaft connected at one end thereof to the bottom. The wall and shaft respectively extends in opposite directions from the bottom. The shaft has at least one inlet duct and at least one outlet duct. The wall has a mouth portion arranged to encircle the portio of the cervix uteri, and the height of the wall is such that, a chamber is defined by the bottom, wall and portio. The outlet duct(s) has at least one opening within the chamber.

Owner:SILFVER VIOLETTA

Method for reducing oxygen donor content of Czochralski monocrystal

InactiveCN104357901AReduced oxygen donor effectLowered byPolycrystalline material growthUnder a protective fluidOxygen donorOxygen content

The invention discloses a method for reducing an oxygen donor content of a Czochralski monocrystal. The method comprises the steps of seeding, shouldering, rotating, obtaining equal diameter, ending and oxygen controlling. The method disclosed by the invention has the advantages as follows: the furnace pressure is reduced to accelerate the pumping of a main pump, increase argon flow, exhaust the SiO volatile gas more quickly, and reduce the content of oxygen which is fed to the molten silicon; the revolving speed of a crucible where the monocrystal grows is reduced, reaction between the molten silicon and the quartz crucible can be slowed down, and the oxygen content in the molten silicon can be reduced, so that the content of oxygen fed to the monocrystal can be reduced, and further the type P monocrystal donor effect can be fundamentally reduced; the revolving speed of the seed crystal can be increased, the latent heat release of crystallization can be quickened, and the cooling speed can be increased, so that the monocrystal can quickly pass through the oxygen donor forming area to reduce the oxygen donor effect.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

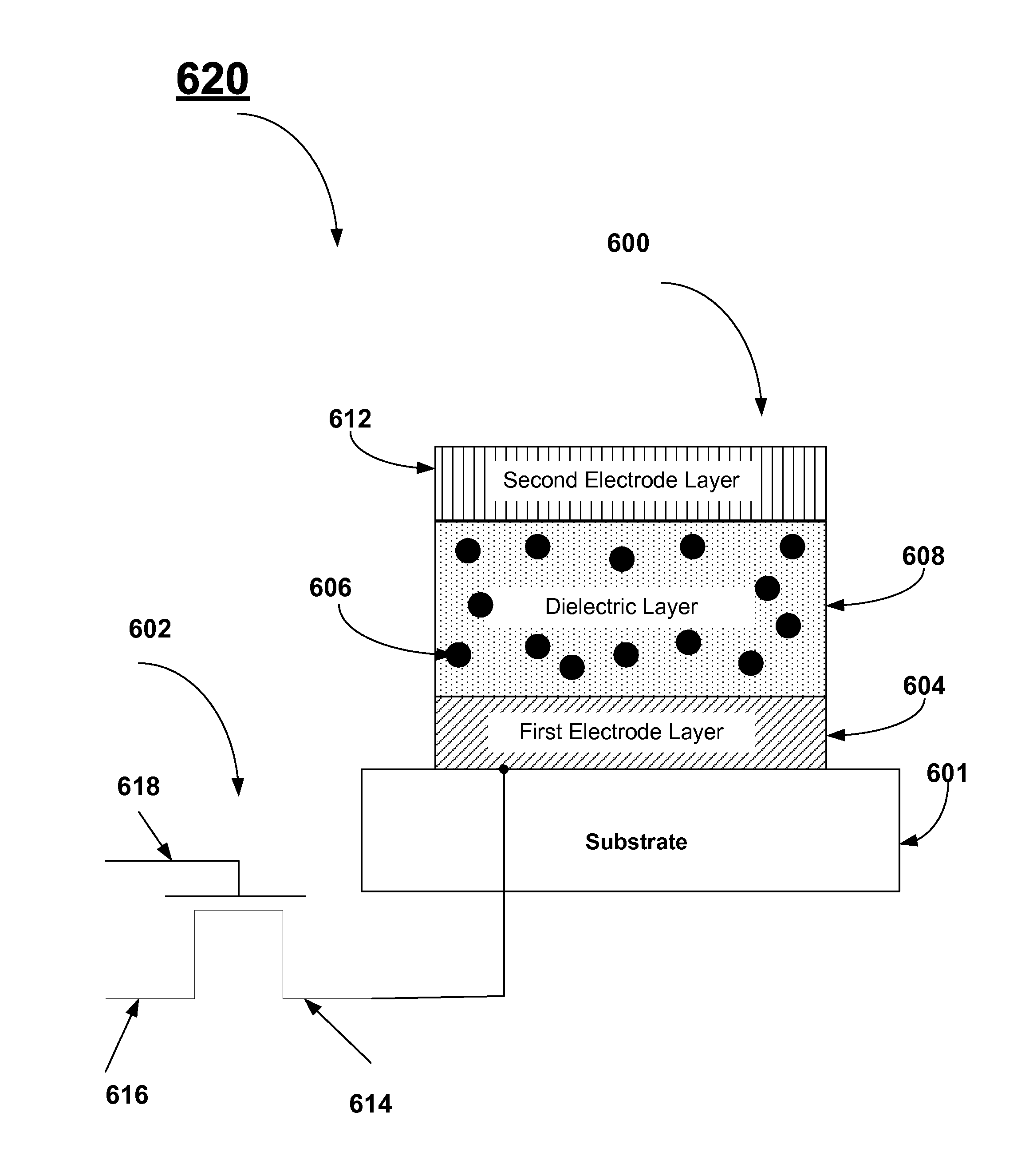

Methods to Improve Leakage of High K Materials

InactiveUS20140170833A1Reduce leakage currentSolid-state devicesSemiconductor/solid-state device manufacturingMetal-insulator-metalDopant

A method for reducing the leakage current in DRAM Metal-Insulator-Metal capacitors includes forming a capacitor stack including an oxygen donor dopant incorporated within the dielectric layer. The oxygen donor dopants may be incorporated within the dielectric layer during the formation of the dielectric layer. The oxygen donor materials provide oxygen to the dielectric layer and reduce the concentration of oxygen vacancies, thus reducing the leakage current.

Owner:INTERMOLECULAR

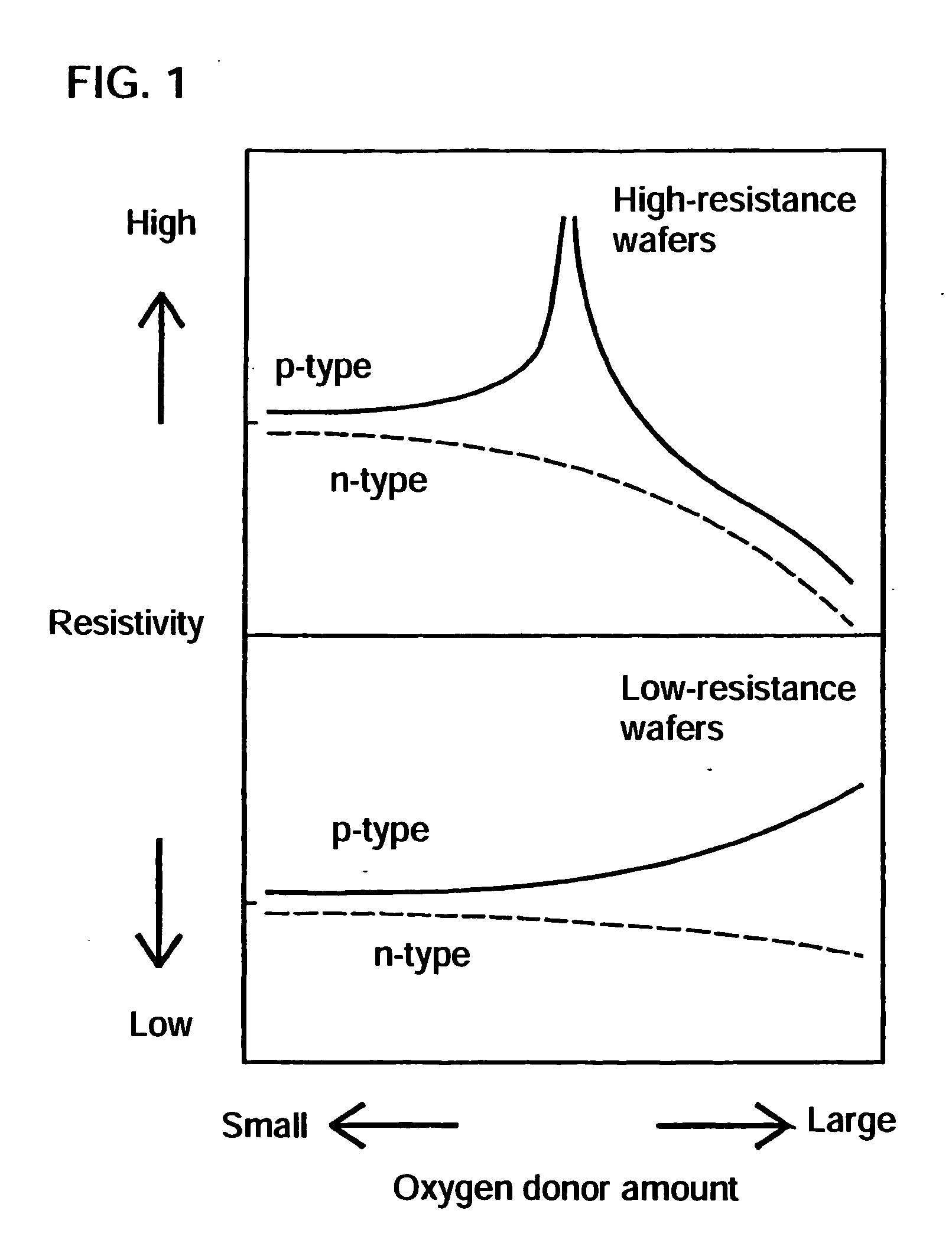

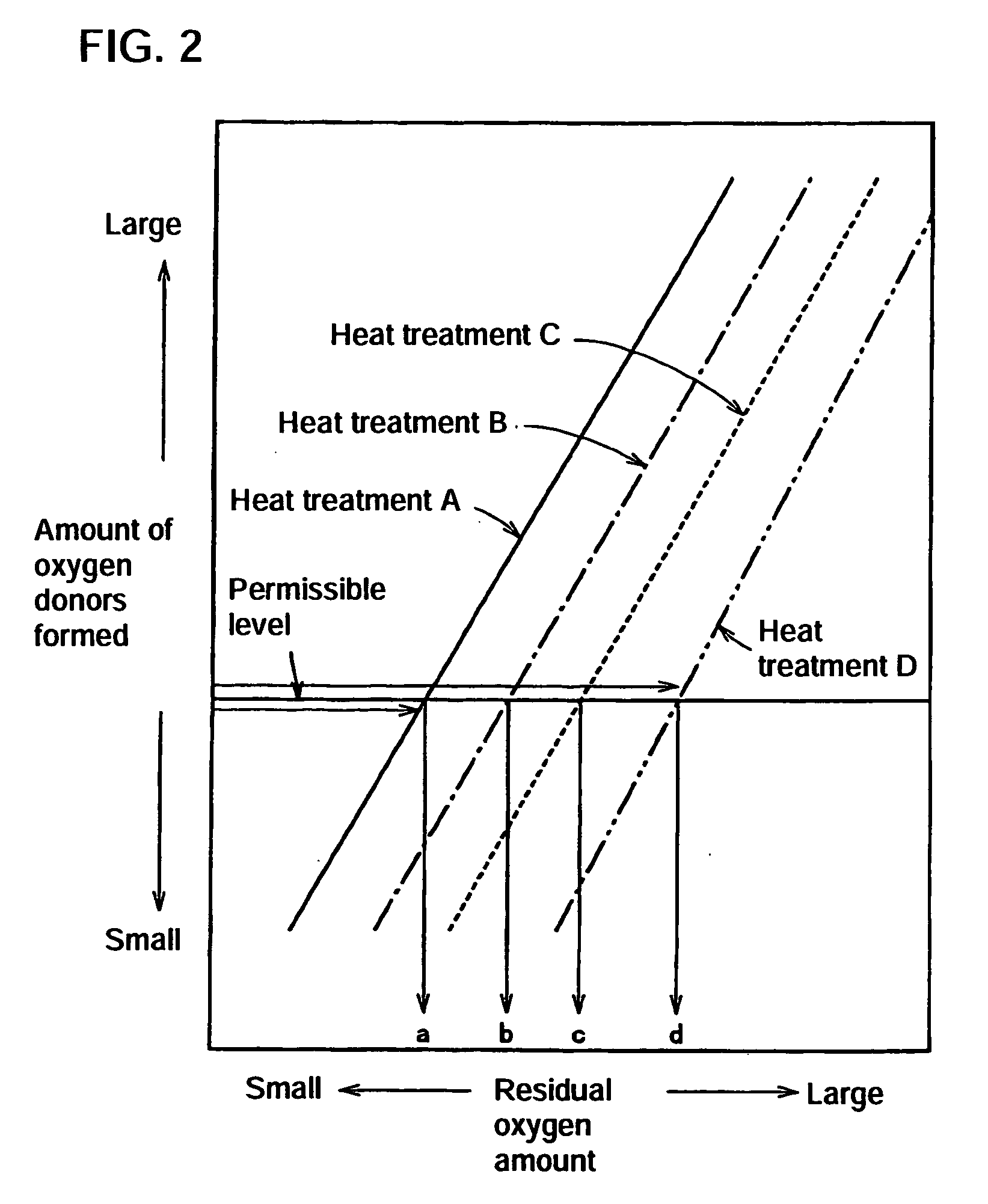

Process for producing high-resistance silicon wafers and process for producing epitaxial wafers and soi wafers (as amended)

ActiveUS20070066033A1Low production costAvoid it happening againPolycrystalline material growthAfter-treatment detailsHigh resistanceElectrical resistance and conductance

By using oxygen-containing silicon wafers obtained by the CZ method and by combining the first heat treatment comprising controlled heat-up operation (ramping) with the second heat treatment comprising high-temperature heat treatment and medium temperature heat treatment in accordance with the process for producing high-resistance silicon wafers according to the present invention, it is possible to obtain high-resistance silicon wafers capable of maintaining their high resistance even after heat treatment in the process of device manufacture while efficiently inhibiting the formation of oxygen donors and preventing changes in resistivity. Further, excellent epitaxial wafers and SOI wafers can be produced using those high-resistance silicon wafers and, therefore, they can be applied in a wide field including high-frequency communication devices and analog / digital hybrid devices, among others.

Owner:SUMCO CORP

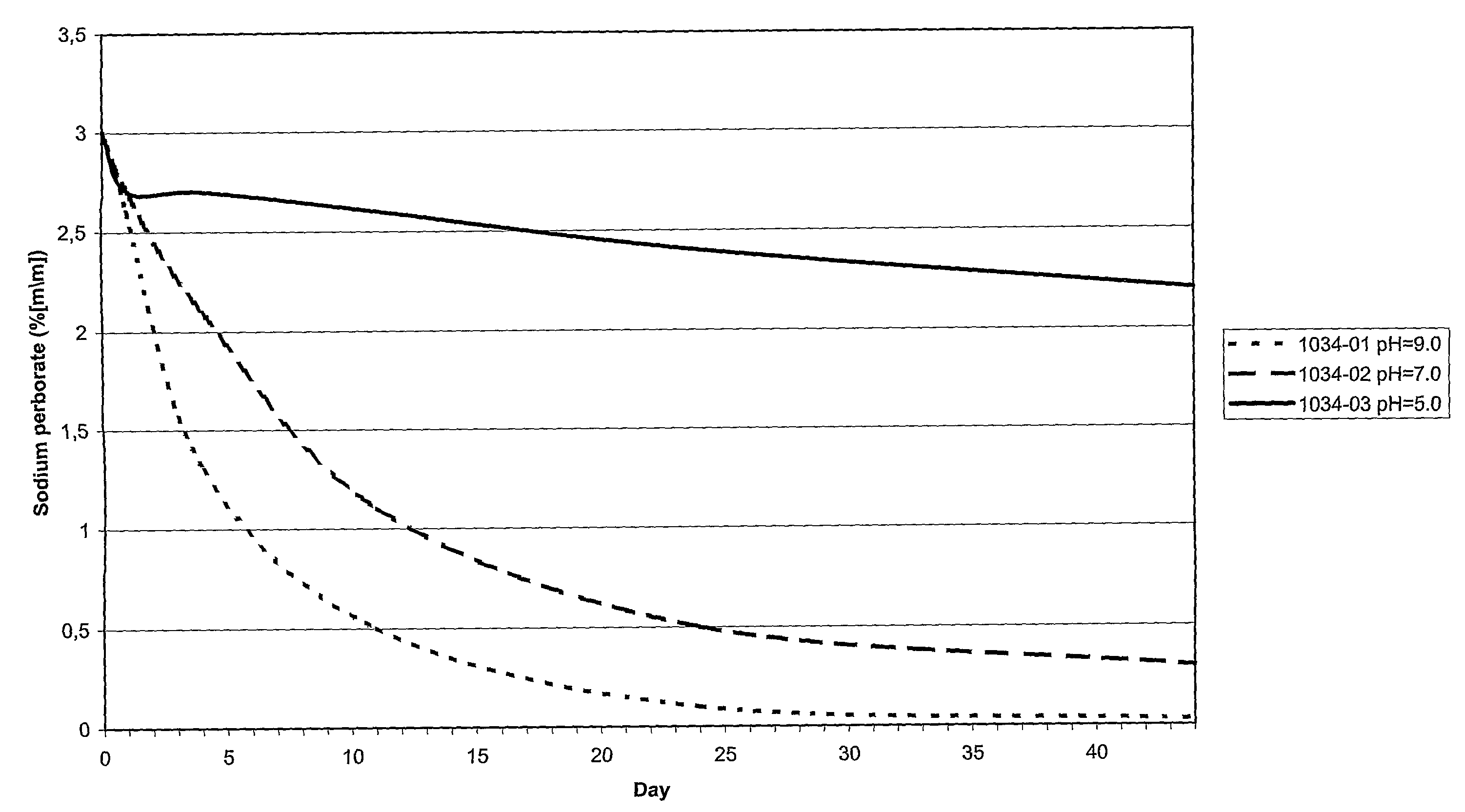

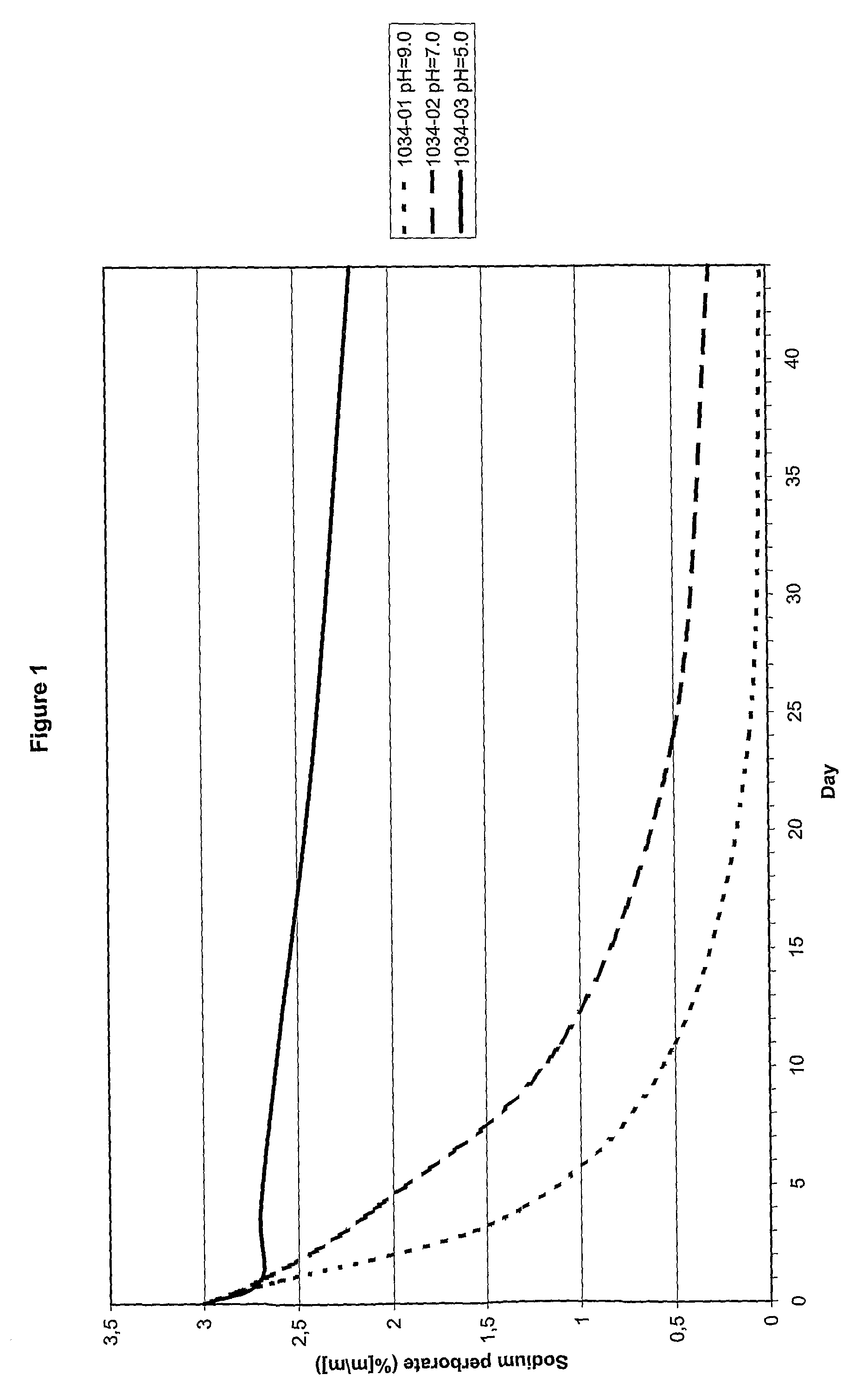

Stabilised Oxygen Releasing Composition

InactiveUS20080274206A1Easy to packSafe to transport and to storeCosmetic preparationsBiocideHalogenOxygen donor

The present invention relates to stabilised liquid oxygen releasing composition comprising a component (a) selected from the salts consisting of cations An+ and anions derived from halogen oxides according to the general formula [OmX]− wherein A is a metal selected from Groups 1 or 2 of the Periodic System of the Elements, X is a halogen atom, m=1-4, n=1 or 2, a component (b) selected from the group of oxygen donors, a component (c) selected from the group of oxygen donor stabilising agents and a component (d) selected from the group of liquid binders. The stabilised liquid oxygen releasing composition can be used in pharmaceutical compositions, cosmetic compositions and food applications, e.g. skin care products, dental care products, tooth whitening products including chewing gums.

Owner:MADURAR NV +1

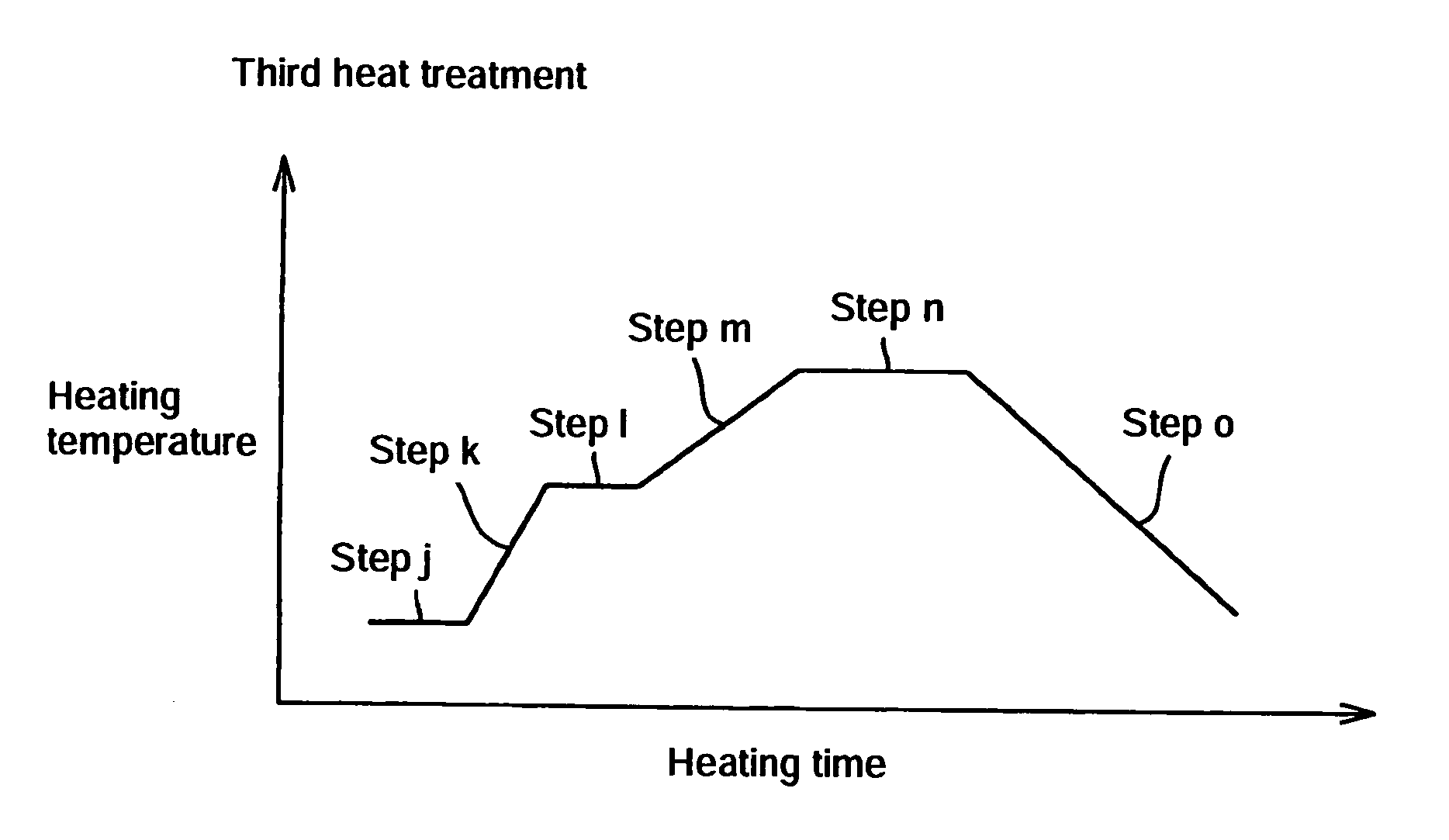

Heat treatment process of semiconductor silicon wafer

ActiveCN102995125AOxygen Donor Effect EliminationOxygen donor effect inhibitionAfter-treatment detailsOxygen donorMonocrystalline silicon

The invention discloses a heat treatment process of a semiconductor silicon wafer. The process comprises the steps of: (1) stabilizing the temperature in heat treatment furnace and stabilizing the temperature in the heat treatment furnace at 640-660 DEG C; (3) placing the semiconductor silicon wafer into a quartz boat orderly and horizontally; (4) opening the heat treatment furnace and pushing the quartz boat which carries the semiconductor silicon wafer quickly into a constant temperature area at 640-660 DEG C of the heat treatment furnace to be processed for 30-45minutes; (5) opening the heat treatment furnace and pulling the quartz boat which carries the semiconductor silicon wafer quickly out of the heat treatment furnace; and (6) quickly placing the quartz boat and the semiconductor silicon wafer at an air cooler to be quickly cooled to room temperature. According to the heat treatment process of the semiconductor silicon wafer provided by the invention, the oxygen donor effect is eliminated and the heat donor effect is inhibited through heat treatment at 650 DEG C and rapid annealing crossing at 350-500 DEG C, meanwhile, no novel donor effect is generated within a short time for treatment at 650 DEG C, so that the real resistivity of the straightly pulled monocrystalline silicon piece can be obtained by the heat treatment process disclosed by the invention.

Owner:ZHEJIANG COWIN ELECTRONICS

Method for manufacturing SOI substrate

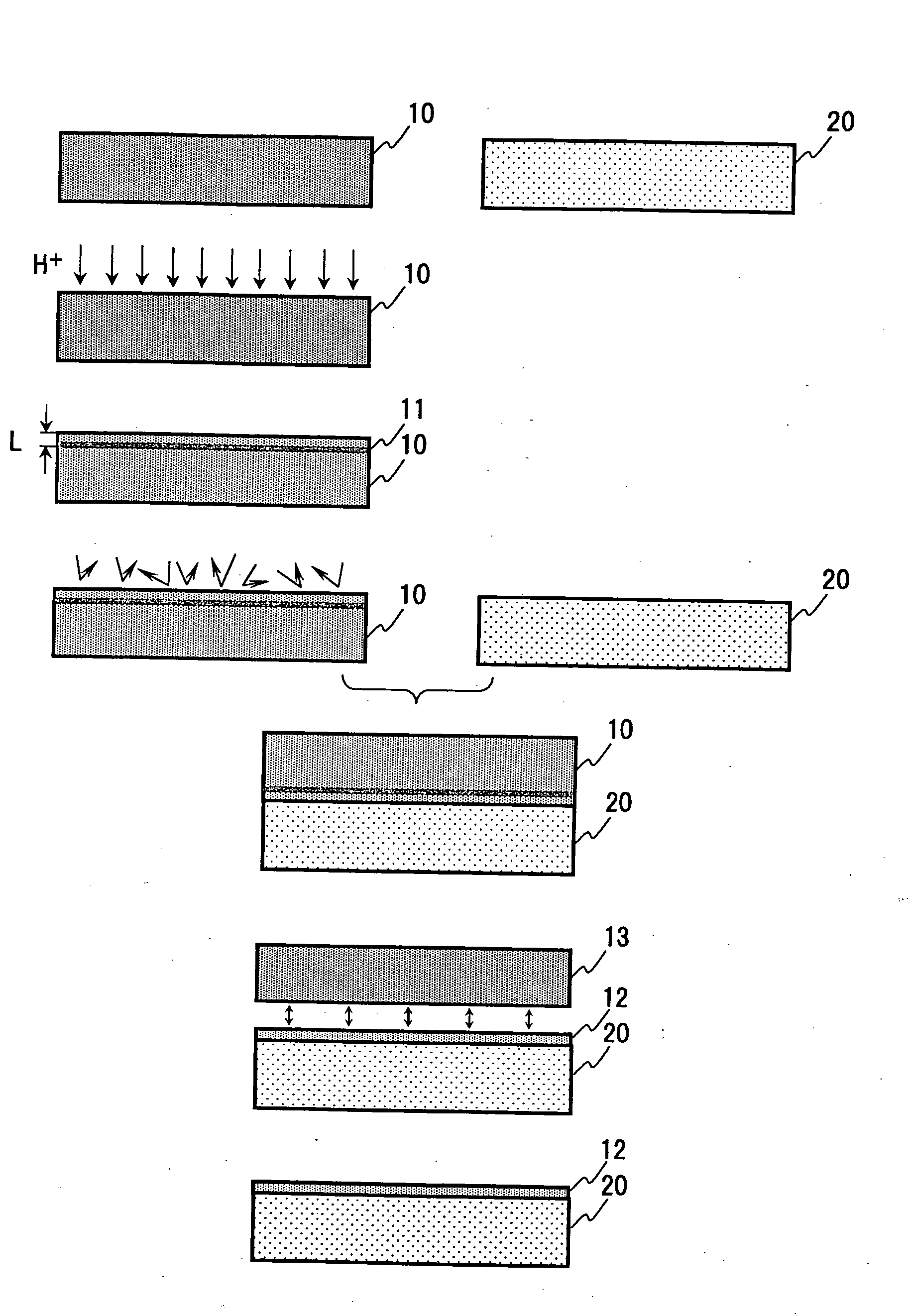

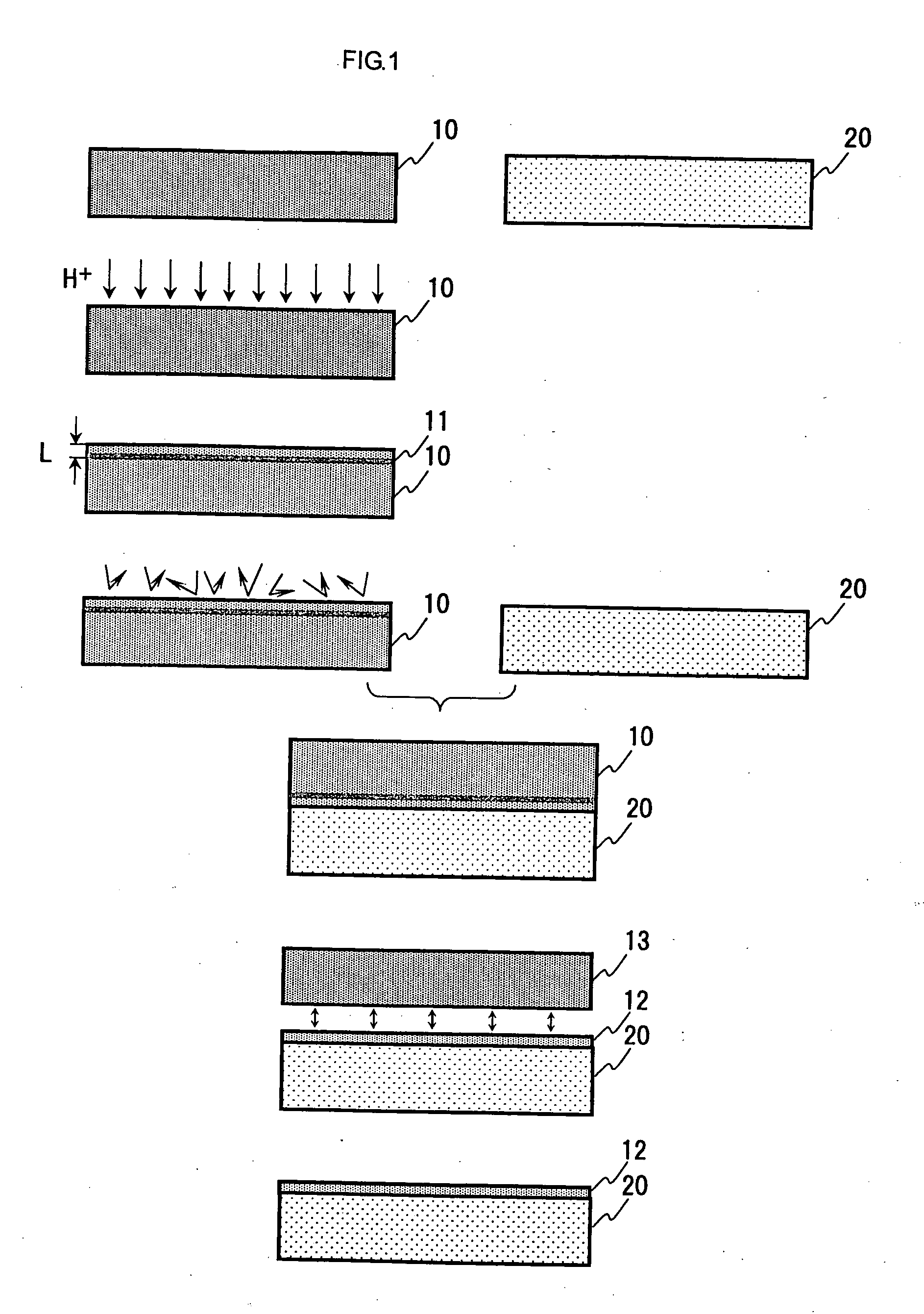

ActiveUS20080254595A1Suppress generationSolid-state devicesSemiconductor/solid-state device manufacturingSoi substrateOxygen donor

An SOI substrate having no worry about a fluctuation in electrical characteristics due to generation of oxygen donors is provided.A silicon substrate 10 used for bonding is a single-crystal Si substrate in which an interstitial oxygen concentration measured by infrared absorption spectrophotometry is equal to or below 1×1018 cm−3. The interstitial oxygen concentration of the single-crystal silicon substrate is set to 1×1018 cm−3 or below since a degree of formation of oxygen donors is strongly dependent on the interstitial oxygen concentration. When the interstitial oxygen concentration of the crystal silicon substrate is set to 1×1018 cm−3 or below, a fluctuation in electrical characteristics (a resistivity) of a silicon layer (an SOI layer) of an SOI substrate can be suppressed to a practically problem-free level. Such a single-crystal silicon substrate can be readily obtained by an MCZ method that can control a convection of a silicon melt by applying a magnetic field or an FZ method that uses no quartz crucible.

Owner:SHIN ETSU CHEM IND CO LTD

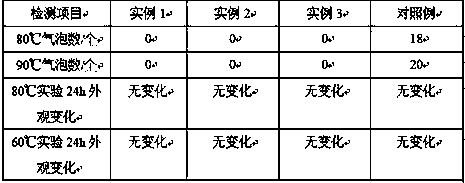

Preparation method of high-weather-resistance fireproof glass interlayer material

InactiveCN109880006AImprove dense structureReduce the probability of air bubblesWeather resistanceSilanes

The invention relates to a preparation method of a high-weather-resistance fireproof glass interlayer material and belongs to the technical field of fireproof materials. According to the preparation method, anhydrous aluminum trichloride and ethyl orthosilicate as reaction precursors and anhydrous diethyl ether as an oxygen donor are used for performing non-hydrolysis preparation of a gel material, a silica sol material is modified through the gel material, through silane modifying, the organic hydrophobic group is more easily grafted on the surface of aerogel, a dense structure is formed through gel coating so as to serve as a defoaming agent material of the gel interlayer, the bubble rate of the material is reduced effectively, meanwhile, by effective bonding between the gel material andthe interlayer gel, the dense structure of the material is effectively improved, and the mechanical property of the material is further improved.

Owner:雷江容

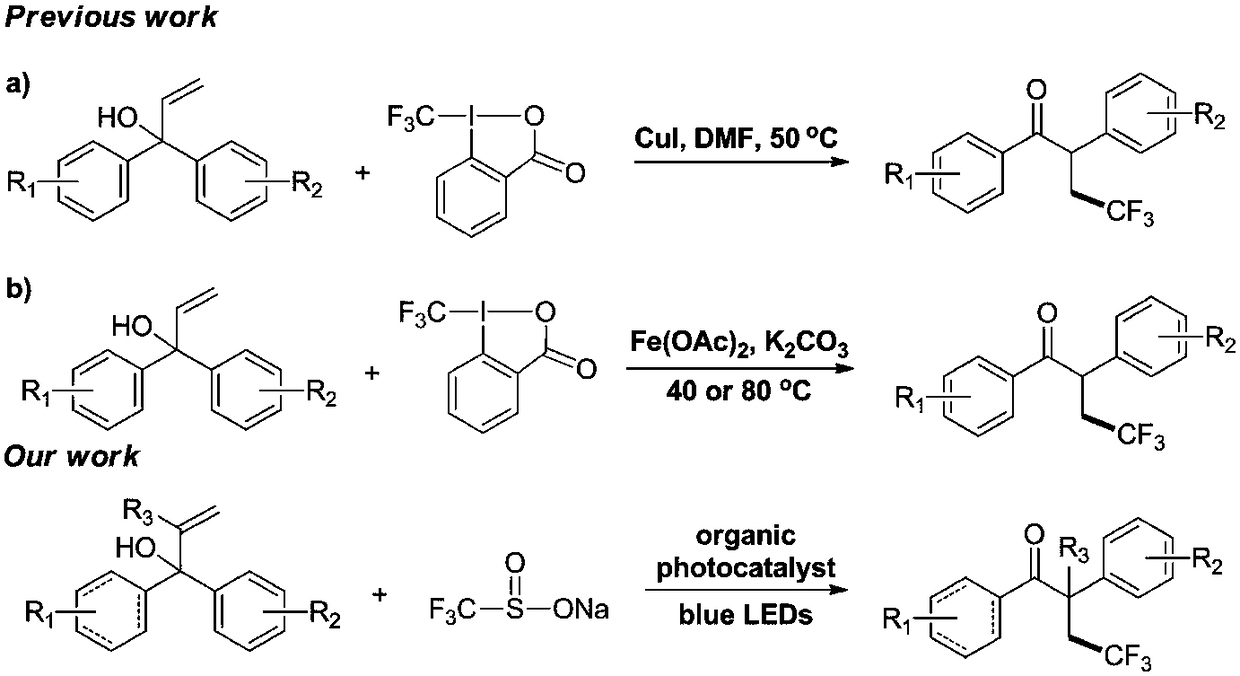

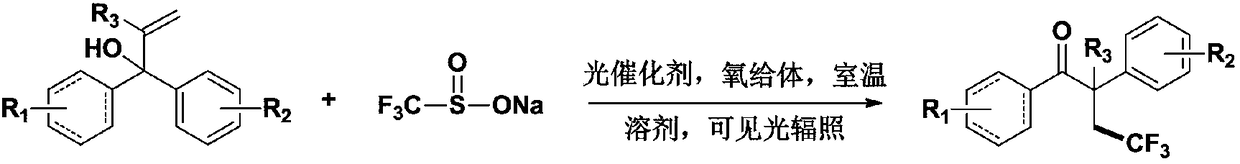

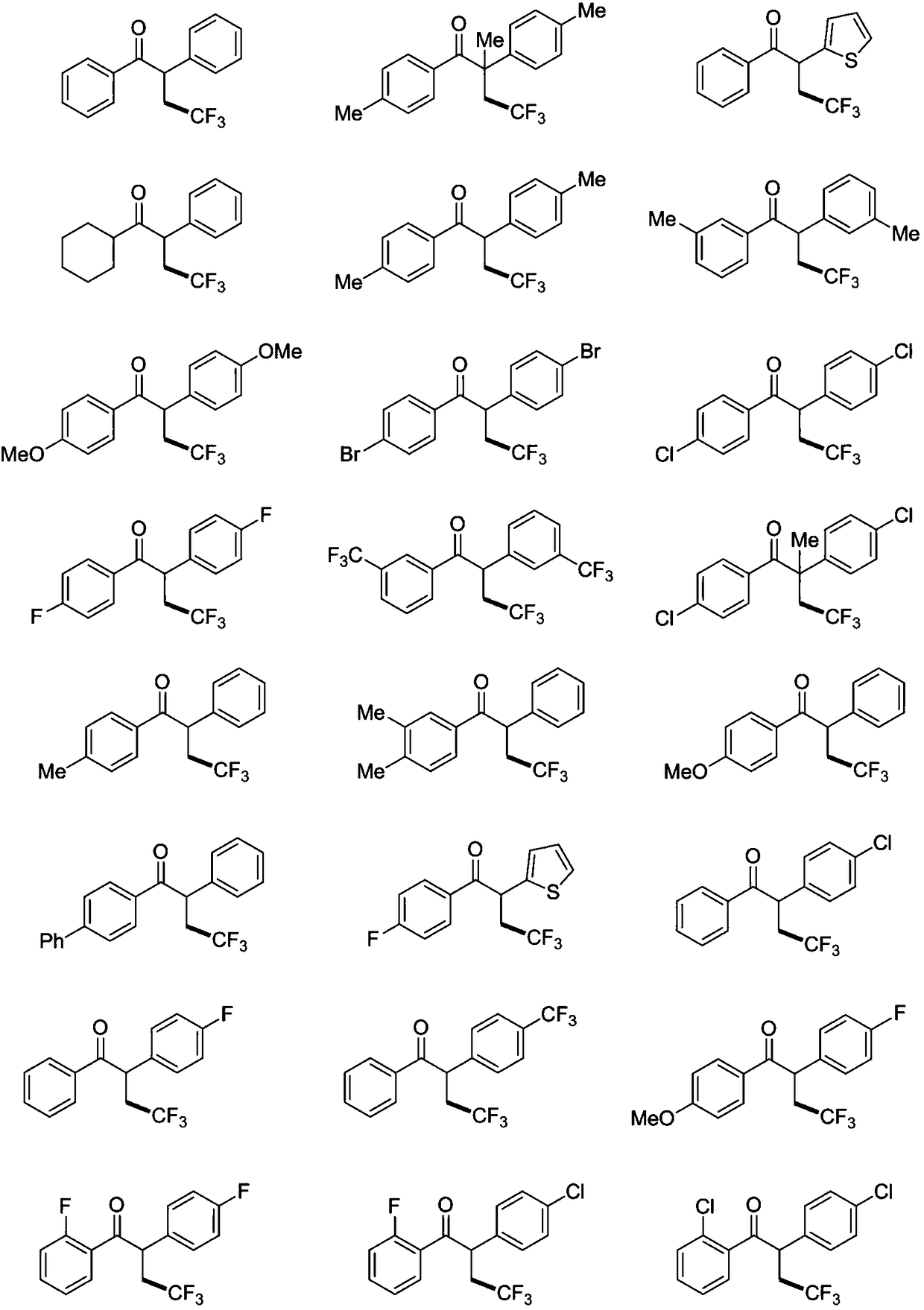

Method for preparing alpha-aryl-beta-trifluoromethyl ketone compound through visible light catalysis

ActiveCN108774121AImprove toleranceLow priceOrganic compound preparationCarbonyl compound preparationOrganic synthesisOxygen donor

The invention discloses a method for preparing an alpha-aryl-beta-trifluoromethyl ketone compound through visible light catalysis, which is characterized in that in an oxygen atmosphere, an alpha-aryl-beta-trifluoromethyl ketone compound is obtained by synthesis of alpha-mono-aryl allyl alcohol compound and sodium trifluoromethanesulfonate as materials under the action of the synergistic effect ofa photocatalyst, visible light, a solvent and an oxygen donor. According to the invention, a new method for preparing the alpha-aryl-beta-trifluoromethyl ketone compound is disclosed by performing visible light photocatalysis reaction on a series of alpha-mono-aryl allyl alcohol material and Langlois reagent under a mild reaction condition. The catalyst system has good tolerance for synthesis ofvarious useful functional groups. According to the method, no strong oxidant or transition metal catalyst is needed, and sodium trifluoromethanesulfonate which is easy to obtain and relatively low incost is taken as a starting material, so that further the application of the synthetic method in organic synthesis is added.

Owner:MINNAN NORMAL UNIV

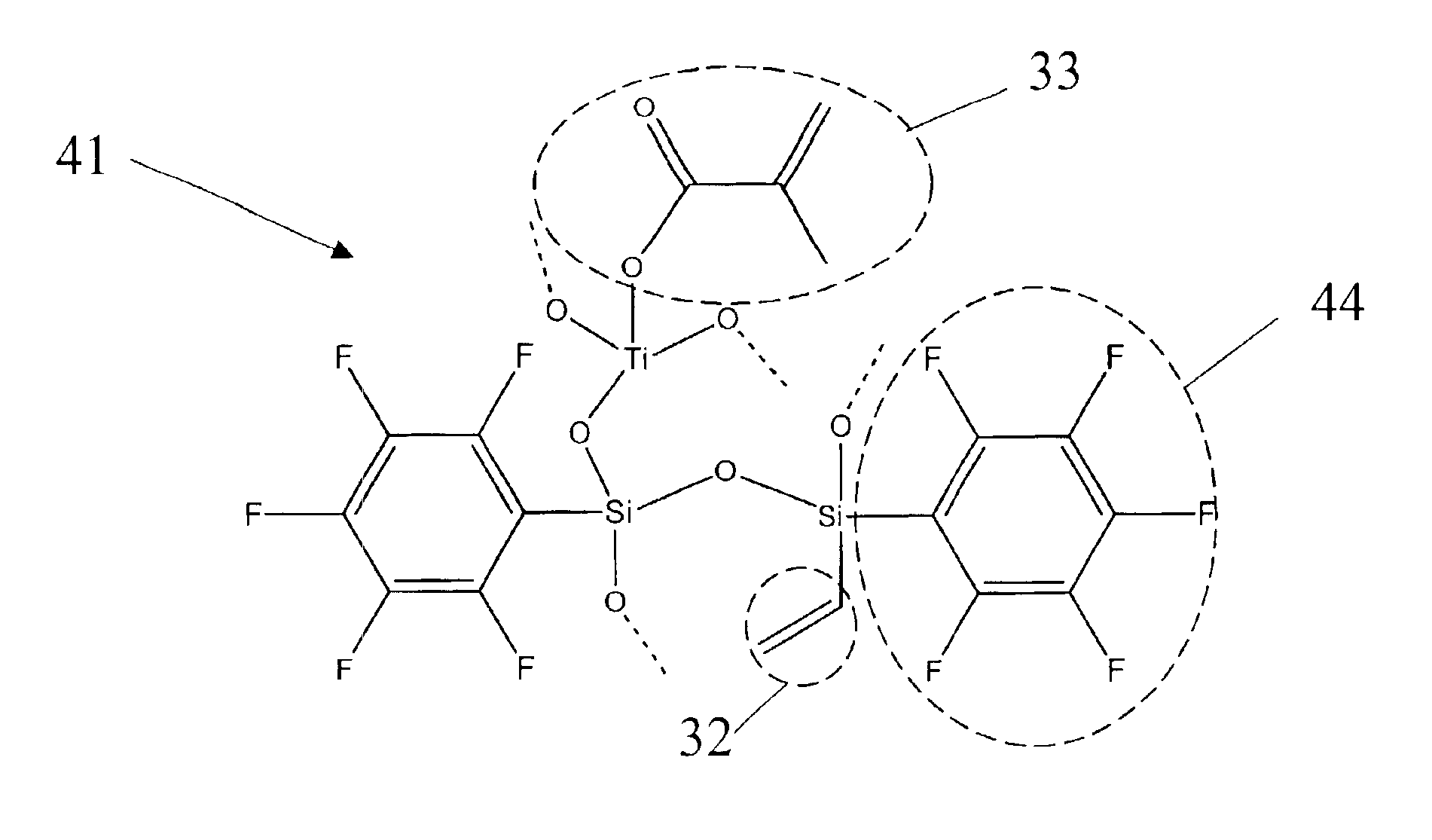

Photo-patternable mono-phase fluorinated organometallic sol-gels for integrated optics and methods of fabrication

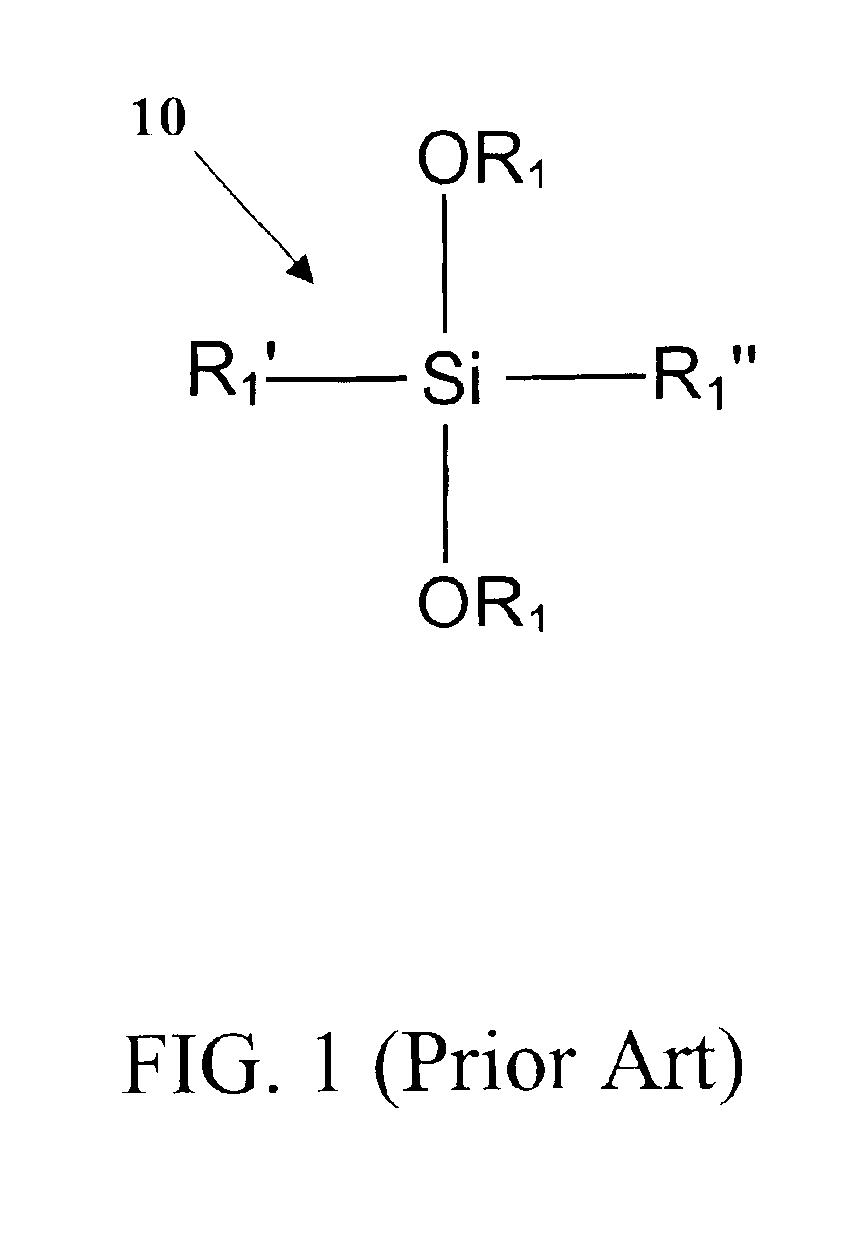

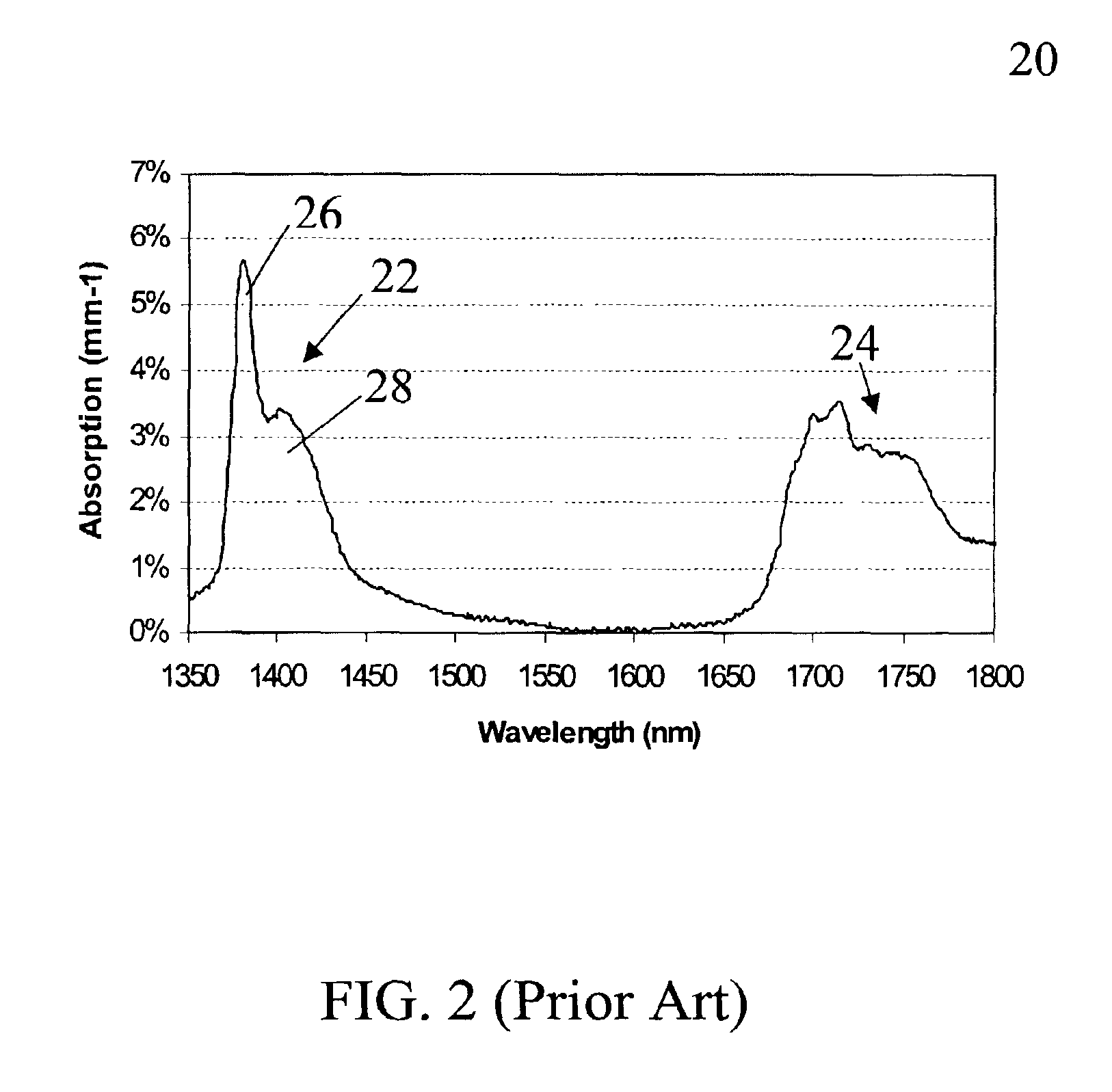

InactiveUS6908723B2Low bend-lossHigh refractive indexPhotography auxillary processesPhotosensitive materialsSilanesOxygen donor

A photo-patternable perfluorinated silane sol-gel material is presented that exhibits a high refractive index and propagation losses below 1 dB / cm at the telecommunication wavelengths. The sol-gels are produced with general formula [(CH2)n,R′—Si(O)2]x—[Si(O)4]y—[R′—Si(O)3]z—[R″(CH2)n—M(O)3]w—[R′″(CH2)n—Si(O)3]v where O is oxygen, Si is silicon, M is a metal alkoxyde known to form bonds with organic compounds through oxygen donor ligands, and where , R″ and R′″ are photo cross-linkable groups, and where (CH2)n are alkyl spacers with n being an integer ≧0. The sol-gels can be fabricated to produce complex waveguide structures directly onto silica-on-silicon substrates with low bending losses.

Owner:NP PHOTONICS A CORP OF DELAWARE

Silicon member and method of manufacturing the same

InactiveUS20060170078A1Easy to controlImprove device yieldSemiconductor/solid-state device manufacturingSemiconductor devicesWaferingSingle crystal

There is provided a silicon member that can prevent the resistivity of a member itself from varying in a semiconductor manufacturing process, in particular, in a plasma processing process, thereby making wafer processing uniform and being not an impurity contamination source to a wafer to be processed, and a method for manufacturing the same. The silicon member having a resistivity of 0.1 Ω·cm or more and 100 Ω·cm or less is manufactured with steps which are manufacturing a P-type silicon single crystal doped with 13 group atoms of a periodic table having an intrinsic resistivity of 1 Ω·cm or more and 100 Ω·cm or less, and changing said P-type silicon single crystal into an N-type silicon single crystal by oxygen donors formed by annealing at a temperature of 300° C. or more and 500° C. or less.

Owner:COVALENT MATERIALS CORP +1

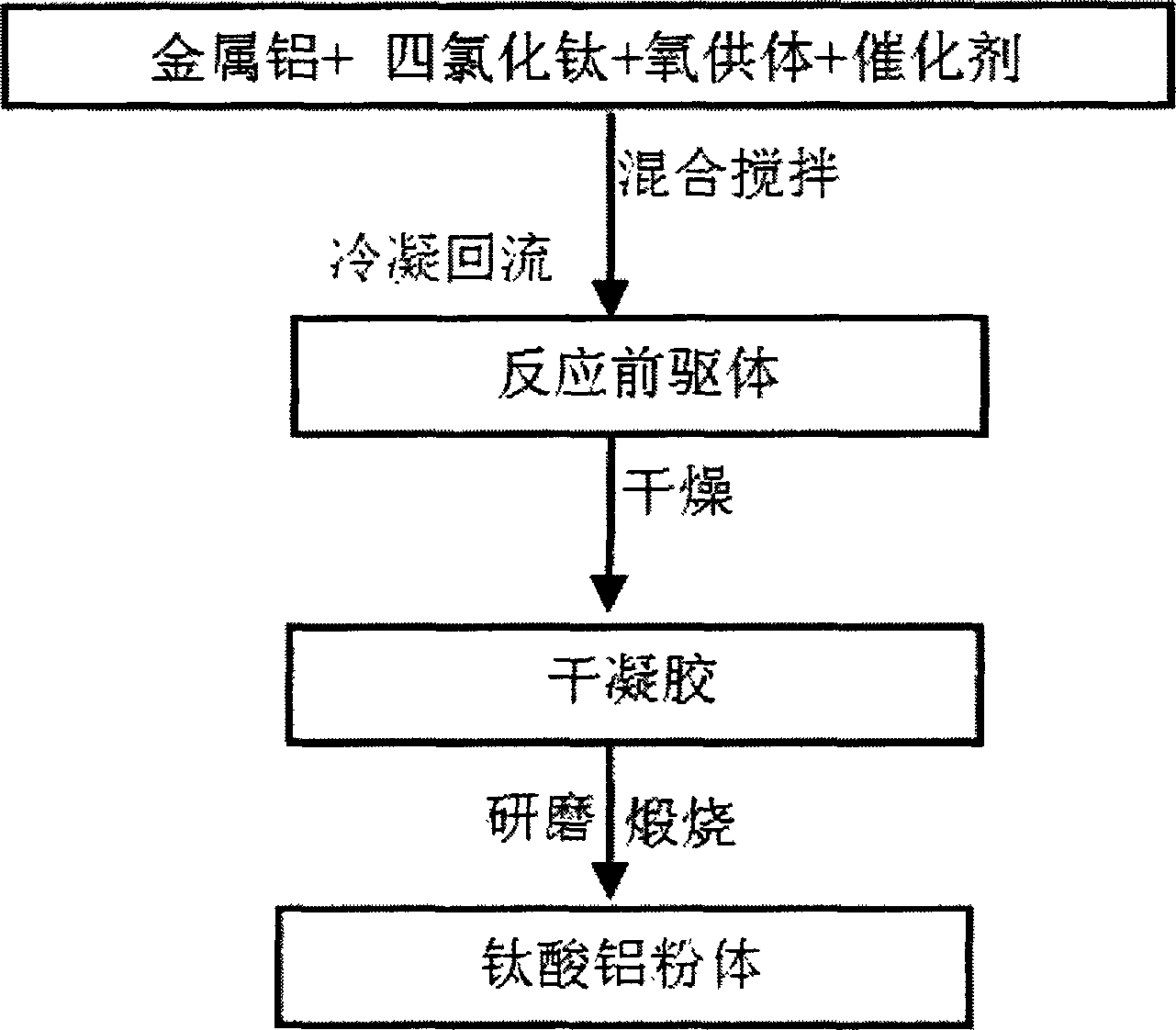

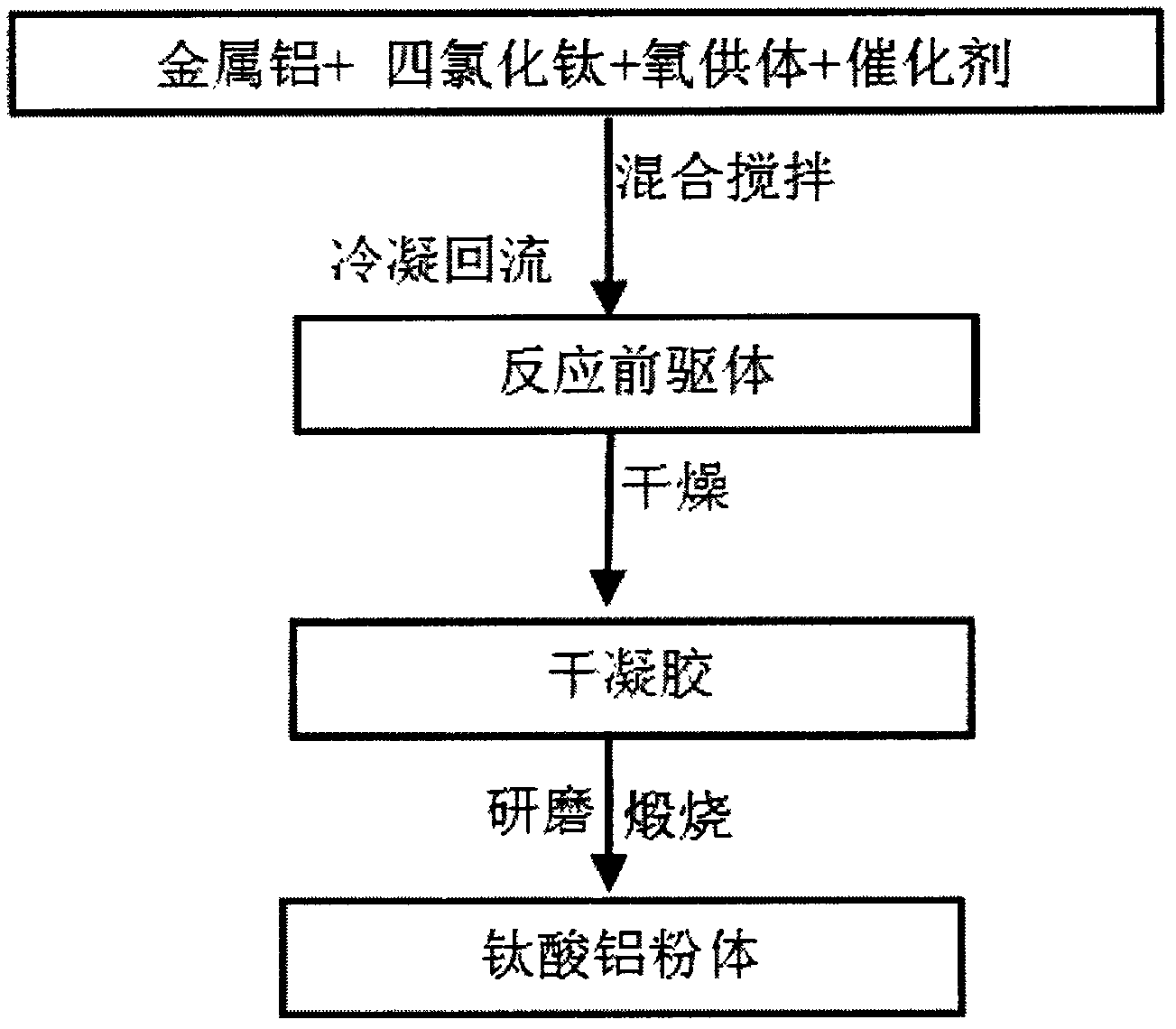

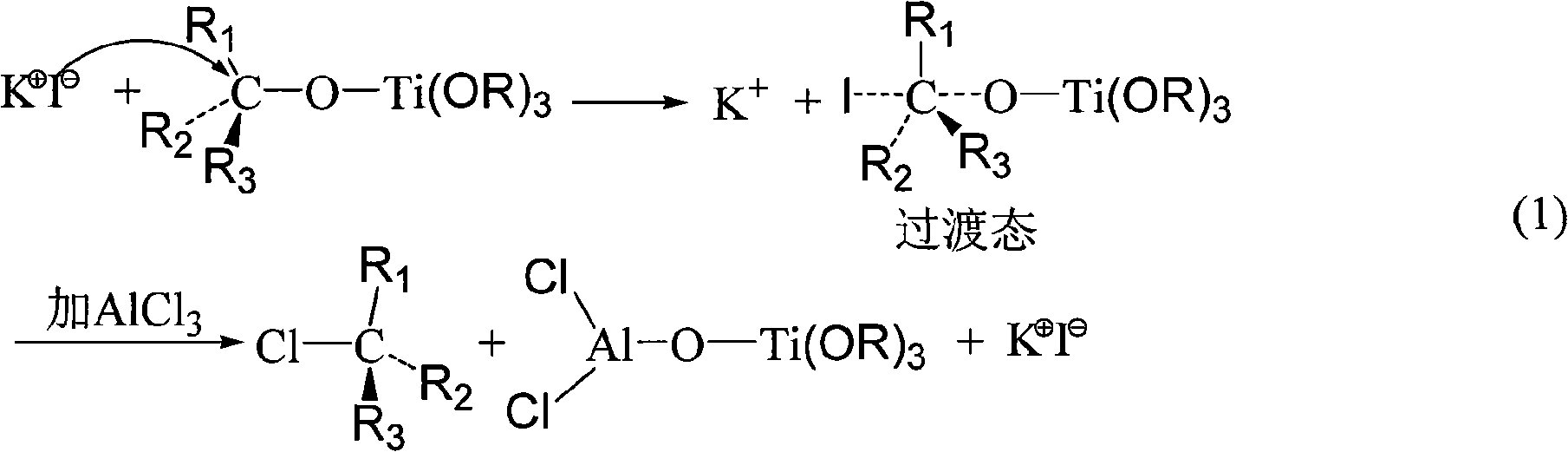

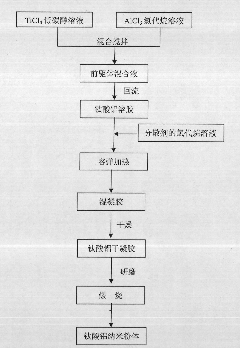

Aluminum titanate powder prepared by taking metal aluminum as aluminum source through non-hydrolytic sol-gel process at low temperature and preparation method thereof

The invention discloses aluminum titanate powder prepared by taking metal aluminum as an aluminum source through a non-hydrolytic sol-gel process at a low temperature and a preparation method thereof. The metal aluminum and titanium tetrachloride are used as precursor raw materials, anhydrous low-carbon alcohol is used as an oxygen donor, and a proper catalyst is selected to prepare the aluminum titanate powder at the low temperature of 750 DEG C. According to the invention, the metal aluminum is utilized to replace aluminum alkoxide and inorganic aluminum salt as the aluminum source, so the preparation method disclosed by the invention has the outstanding advantages of cheap reaction raw material, simple process, low synthesis temperature and the like, and is suitable for industrial massproduction.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Method for preparing aluminium titanate film by non-hydrolytic sol-gel process

InactiveCN101274776ASynthesis temperature is lowShort manufacturing cycleTitanium compoundsOxygen donorDysprosium titanate

The invention discloses a method for preparing an aluminum titanate film by a non-hydrolytic sol-gel technique. Anhydrous aluminum chloride and titanium tetrachloride are taken as precursors and low-carbon alcohol is taken as an oxygen donor; or the anhydrous aluminum chloride and titanium alkoxide are taken as the precursors and precursor mixing liquid is prepared according to the stoichiometry of aluminum titanate; a catalyzer is added into the precursor mixing liquid for backflow at 110 DEG C for 0.5h to 24h; then a solvent AGSE and a quaternary ammonium salt AGSE solution are added into the precursor mixing liquid to prepare aluminum titanate sol; a drying control chemical additive is added to prepare aluminum titanate filming sol after aging; the aluminum titanate filming sol is then filmed and dried to prepare an aluminum titanate dried gel film; filming can be carried out for a plurality of times till required film thickness is obtained and finally heat treatment at 750 DEG C is carried out to obtain the even and compact aluminum titanate film. The method has the advantages of low synthesizing temperature, simple technique, low cost of raw materials, etc. of the aluminum titanate film.

Owner:JINGDEZHEN CERAMIC INSTITUTE

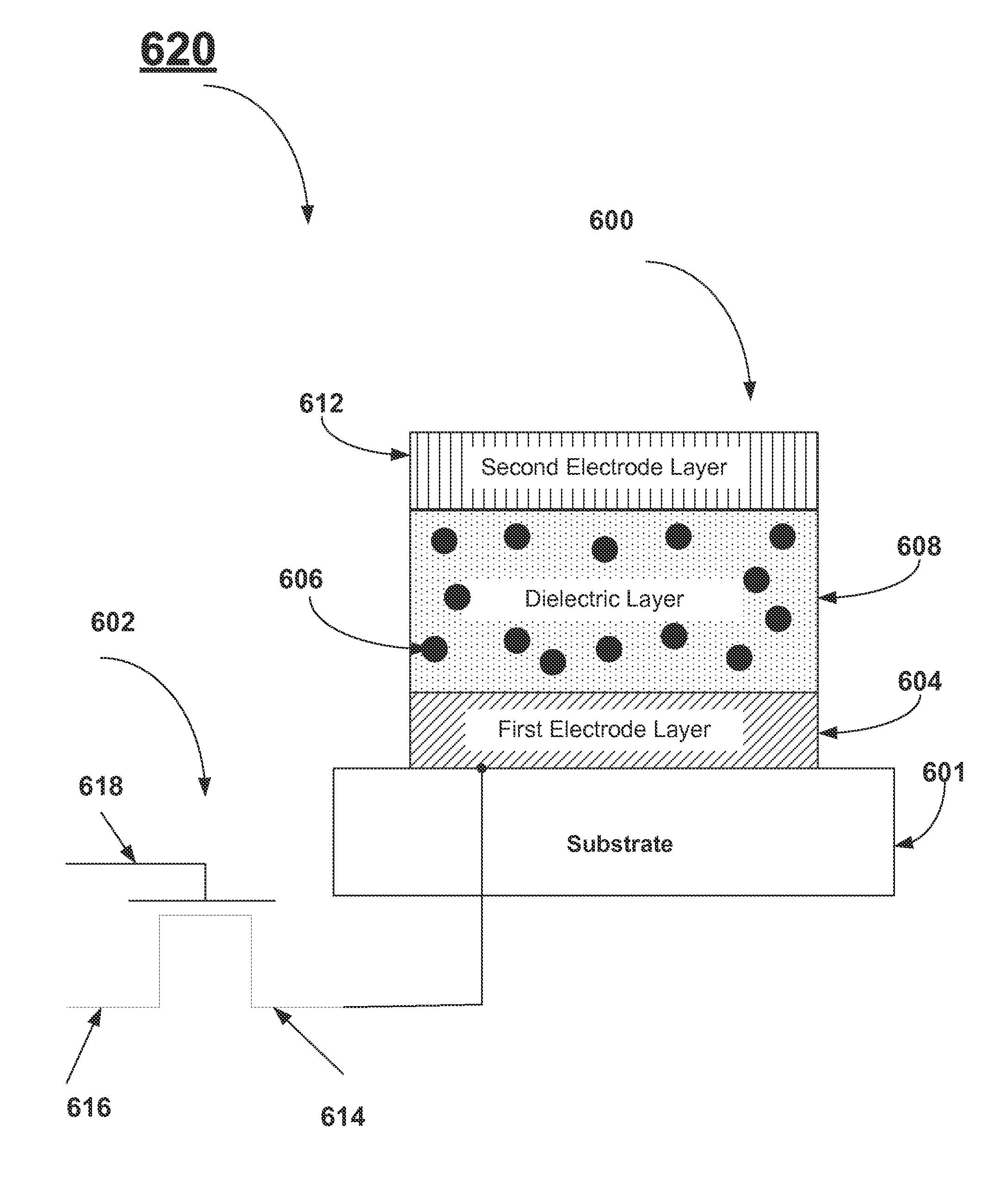

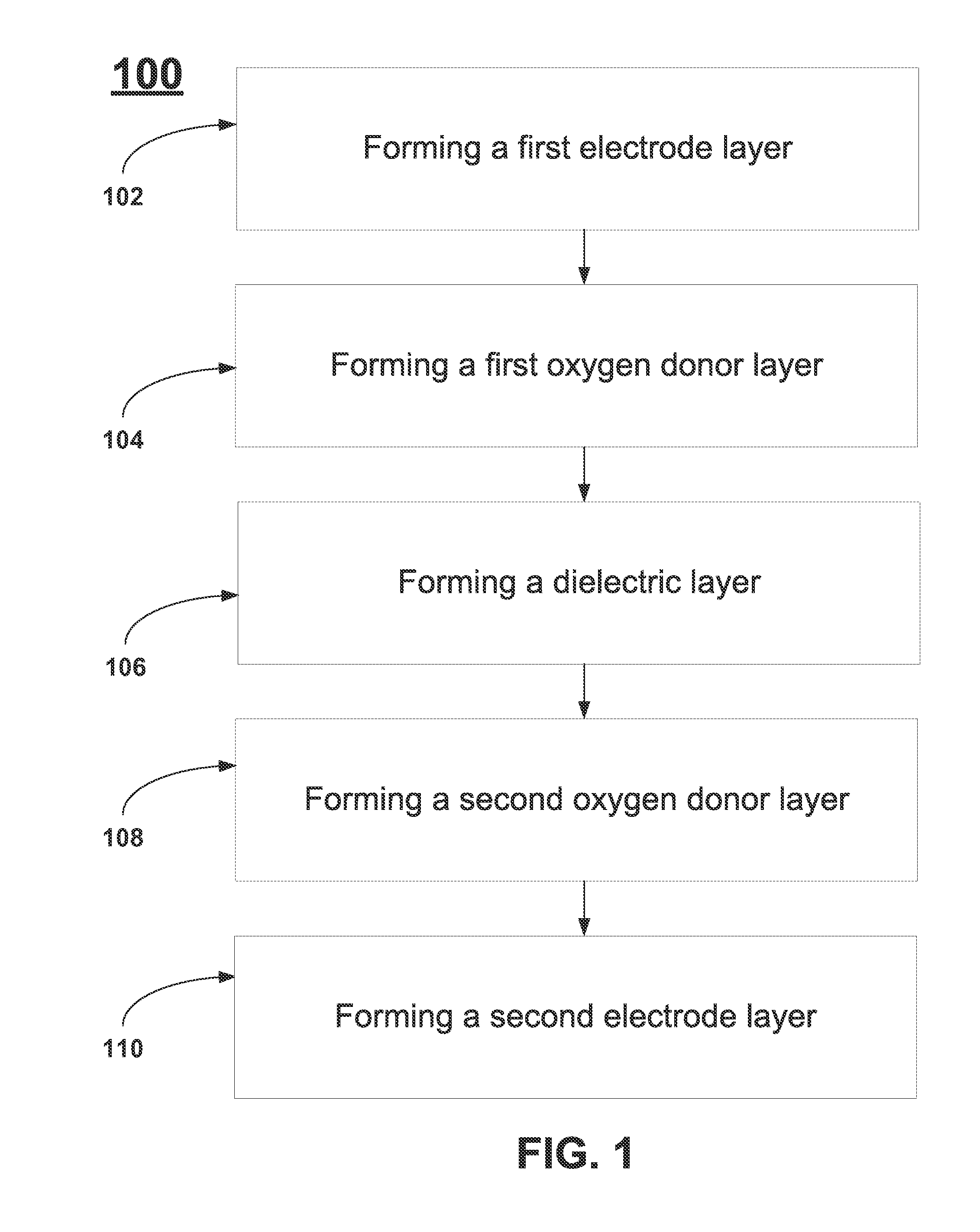

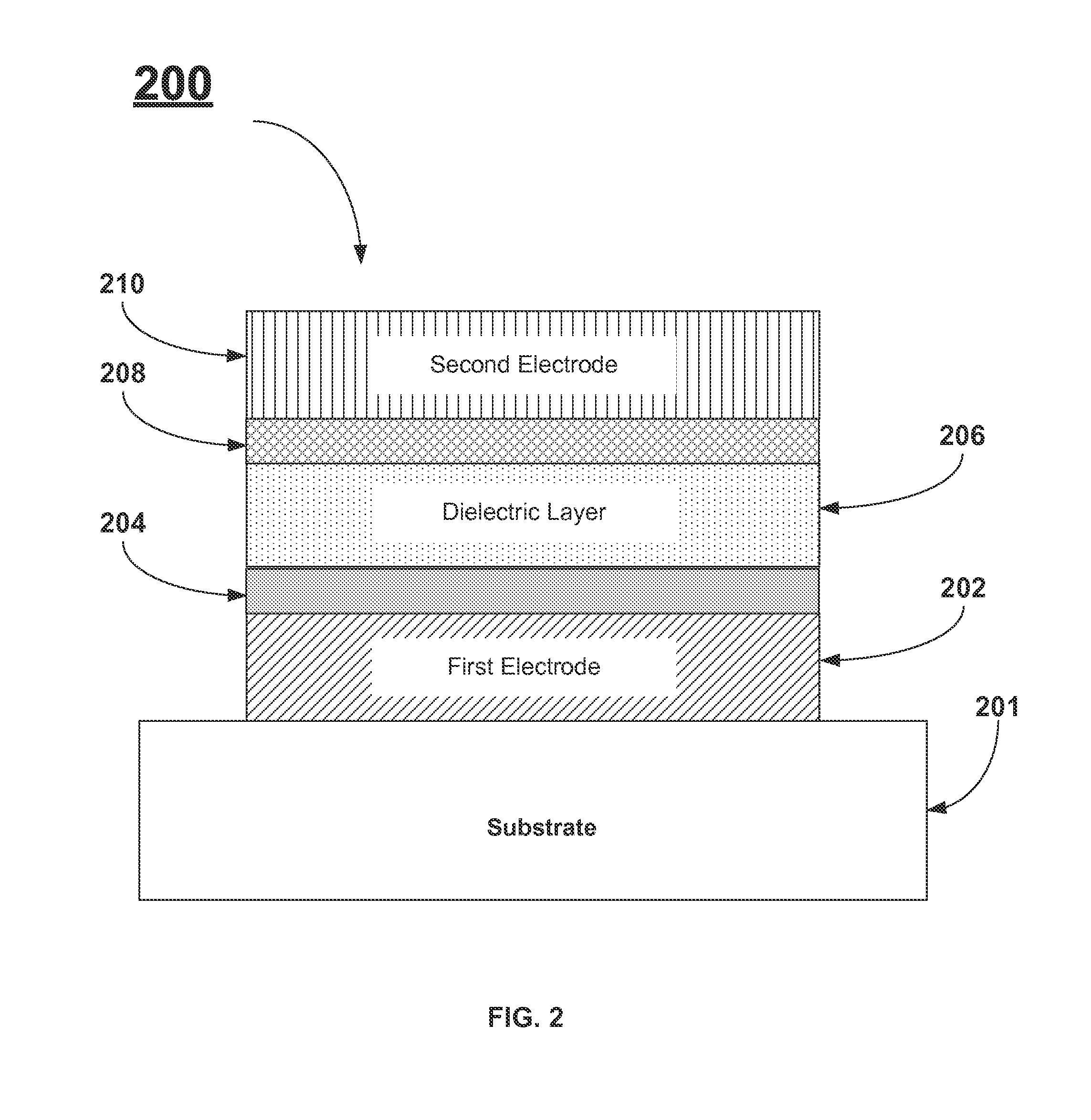

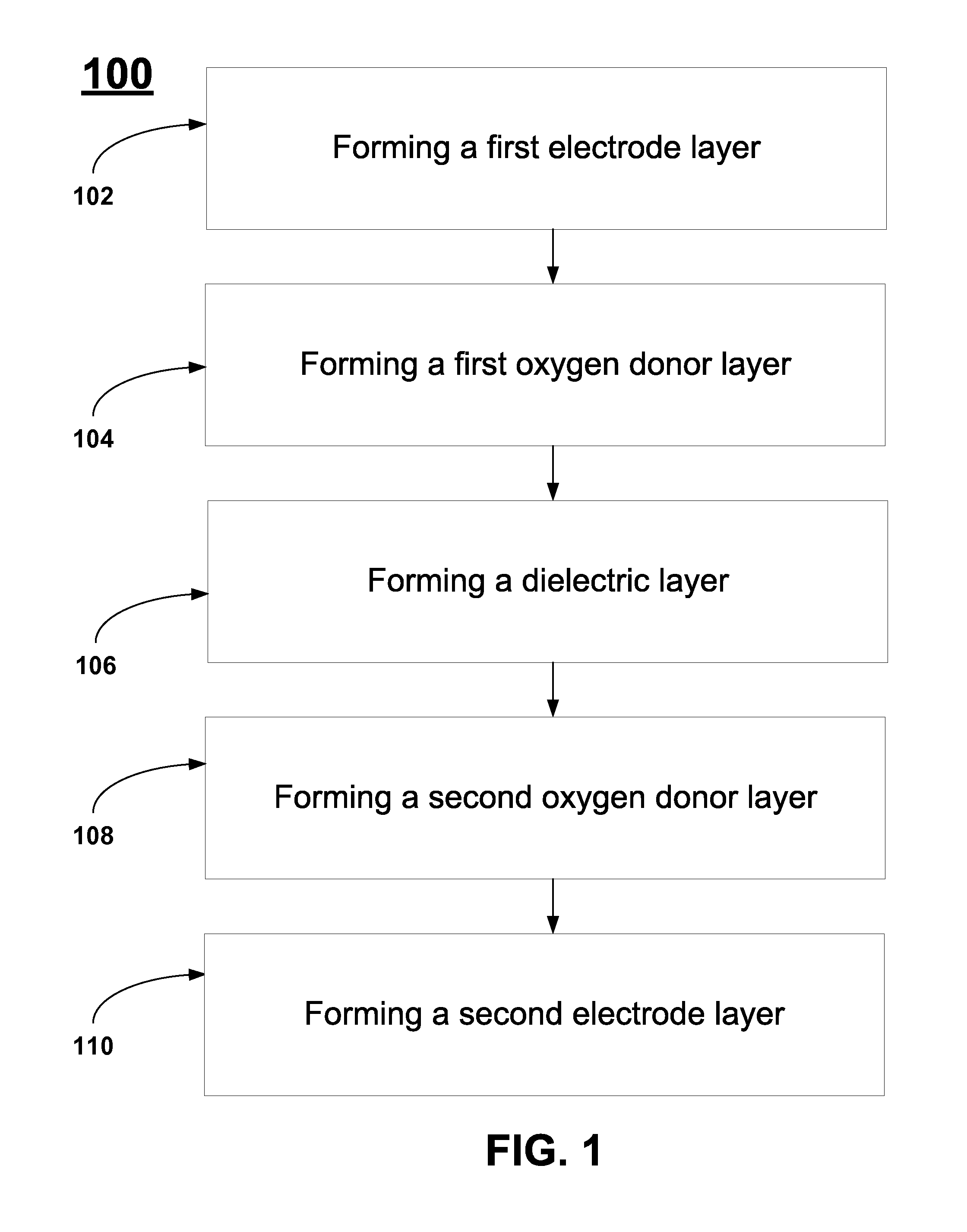

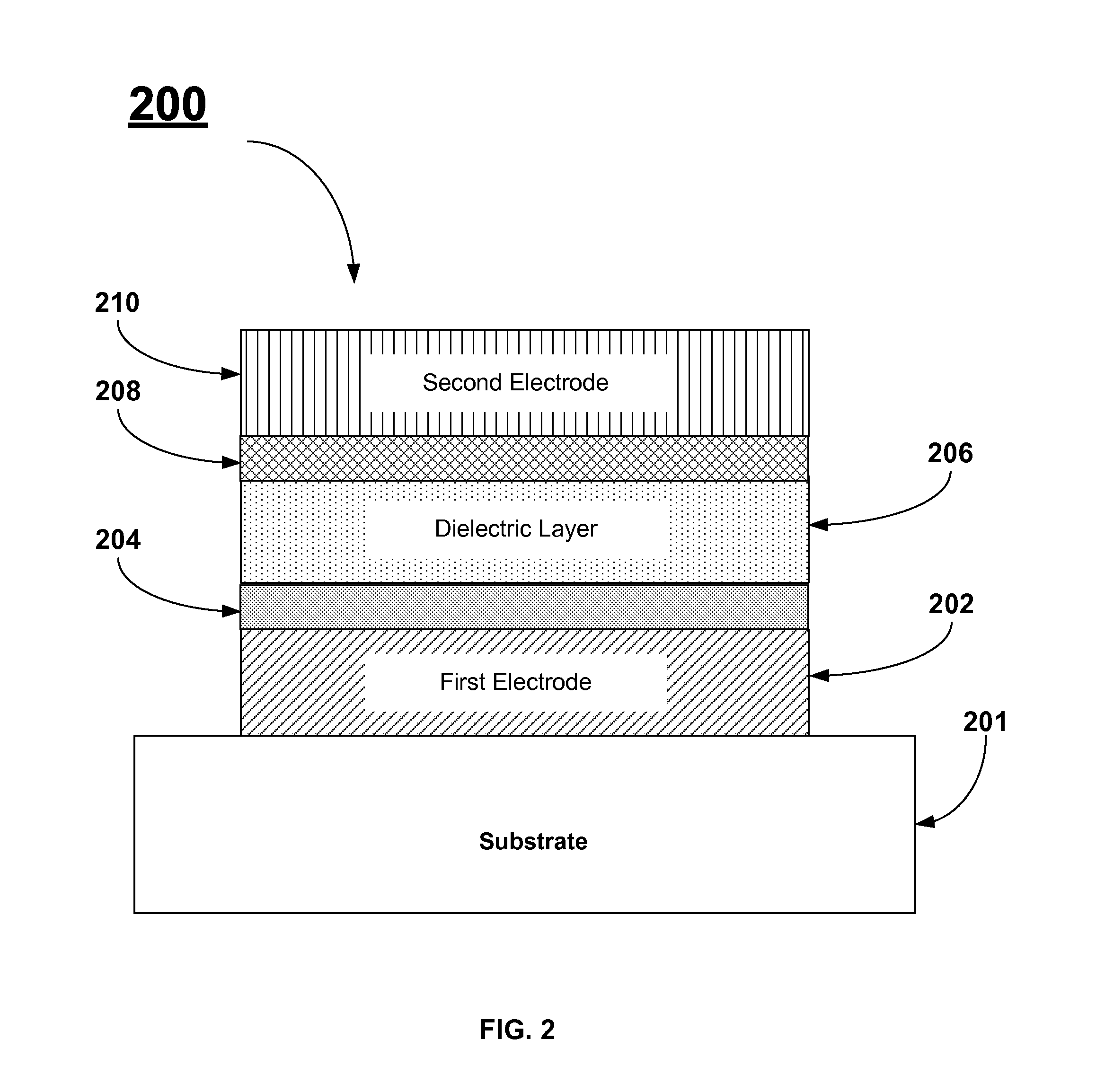

Methods to improve leakage of high k materials

InactiveUS20140167221A1Reduce leakage currentSolid-state devicesSemiconductor/solid-state device manufacturingMetal-insulator-metalDopant

A method for reducing the leakage current in DRAM Metal-Insulator-Metal capacitors includes forming a capacitor stack including an oxygen donor layer inserted between the dielectric layer and at least one of the two electrode layers. In some embodiments, the dielectric layer may be doped with an oxygen donor dopant. The oxygen donor materials provide oxygen to the dielectric layer and reduce the concentration of oxygen vacancies, thus reducing the leakage current.

Owner:INTERMOLECULAR

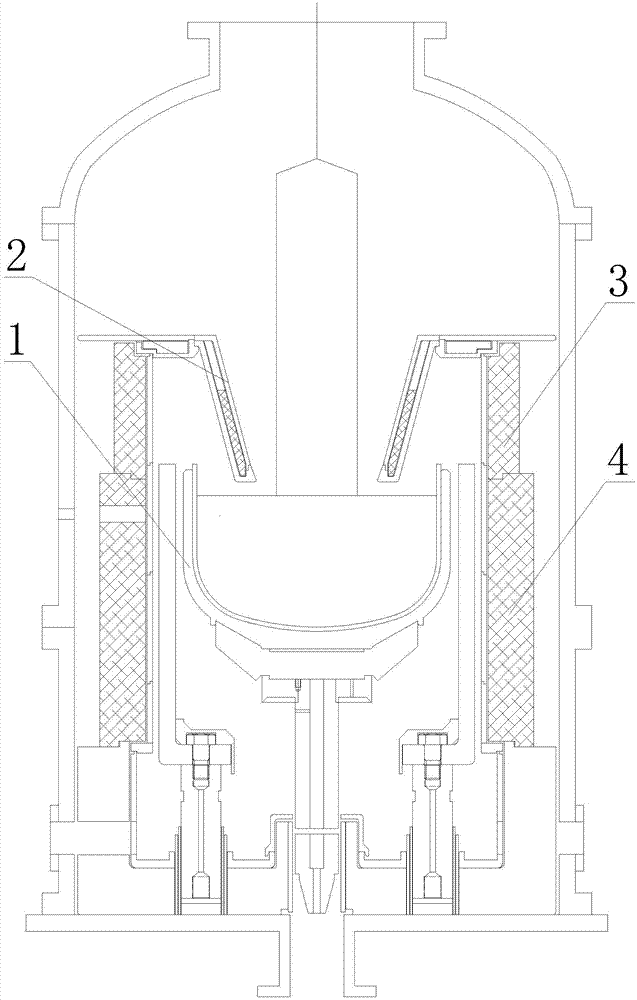

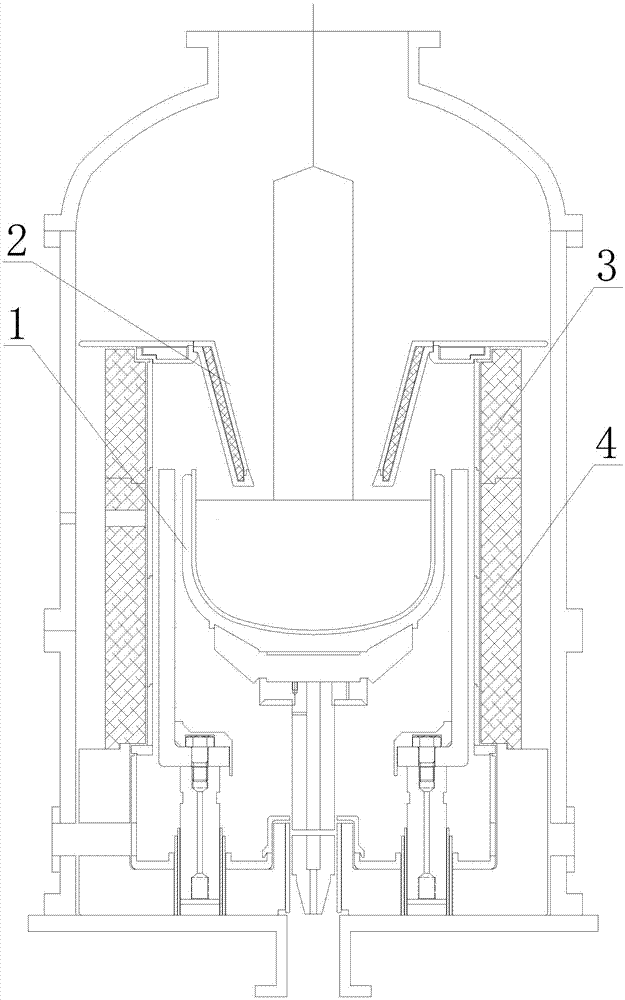

Production technology for controlling oxygen donor single crystal

The invention relates to a production technology for controlling oxygen donor single crystal. The production technology comprises the following steps: stretching the neck, shouldering, turning the shoulder, equalizing diameter, ending and controlling oxygen. The production technology is characterized in that in all steps, the liquid level inside a crucible (1) in a single crystal furnace is always kept at a high pan level; the high pan level is the distance, namely 15-25mm, between the liquid level inside the crucible (1) and the bottom of a diversion screen (2). The production technology has the beneficial effects that the time of the single crystal in an oxygen donor production space is reduced by control on the rotating speed of seed crystal in the production step, control on the rotating speed of the crucible, control on the ascending speed of the crucible, control on the flow of an inert gas, and improvement of an inner thermal insulation layer of the single crystal furnace and a diversion screen insulation layer, so as to reduce the oxygen donor.

Owner:曲靖晶龙电子材料有限公司

Method for preparing stabilizing aluminum titanate at low temperature by non-hydrolytic sol-gel process

InactiveCN101696030AImproved resistance to thermal decompositionTitanium compoundsAlcoholBarium titanate

The invention discloses a method for preparing stabilizing aluminum titanate at low temperature by a non-hydrolytic sol-gel process. In the method, anhydrous aluminum choride and titanium tetrachloride are used as precursors, anhydrous low-carbon alcohol is used as an oxygen donor, and ferric salt or magnesium salt or a compound of the ferric salt and the magnesium salt is used as a stabilizing agent, dry aluminum titanate gel is prepared through the non-hydrolytic sol-gel process, and finally the stabilizing aluminum titanate is obtained through calcining at 750 DEG C. The method for preparing the stabilizing aluminum titanate at low temperature has the prominent advantages of low synthesis temperature, short period, low cost, easy control, and the like.

Owner:JINGDEZHEN CERAMIC INSTITUTE

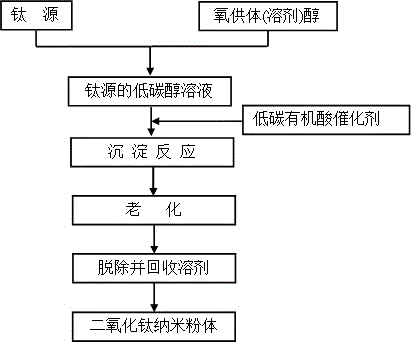

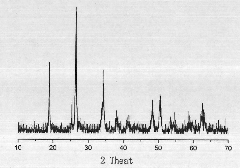

Method for preparing titanium oxide nano powder at low temperature by non-water-precipitation process

ActiveCN106365198AShorten the production cycleEasy to removeMaterial nanotechnologyTitanium dioxideAlcoholCarbon.organic

The invention discloses a method for preparing titanium oxide nano powder at low temperature by a non-water-precipitation process. The method comprises the following steps: taking a proper amount of oxygen donor alcohol as a solvent, dissolving a certain amount of titanium source in the oxygen donor alcohol, stirring uniformly, adding an anhydrous low-carbon organic acid as a catalyst, carrying out oil-bath heating until the precipitation reaction is complete, carrying out aging and solvent removal treatment on the precipitated slurry, and finally, drying the wet precipitated material to obtain the nano titanium oxide powder. The method has the outstanding characteristics of simple process, low control requirements, short preparation period, no pollution and the like, and thus, has wide application prospects.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Method for preparing aluminum titanate nano powder by non-hydrolytic sol-gel process

InactiveCN101823762AProblems affecting the effect of low temperature synthesisInhibition of agglomerationNanostructure manufactureTitanium compoundsAlcoholOxygen donor

The invention discloses a method for preparing an aluminum titanate nano powder by a non-hydrolytic sol-gel process, which comprises the following steps of: using anhydrous aluminum trichloride and titanium tetrachloride as precursors, using a low-carbon alcohol as an oxygen donor, uniformly mixing a low-carbon alcohol solution of the titanium tetrachloride and a chloroalkyl solution of the aluminum trichloride, then refluxing for 8-10 hours in an oil bath at 80-100 DEG C, adding a dispersant, stirring uniformly, loading in a pressure vessel, heating for 15-24 hours at 110-130 DEG C to form a wet gel, drying, grinding and calcining for 15-60 minutes at 750-800 DEG C to obtain the aluminum titanate nano powder with high synthetic ratio and good dispersivity.

Owner:JINGDEZHEN CERAMIC INSTITUTE

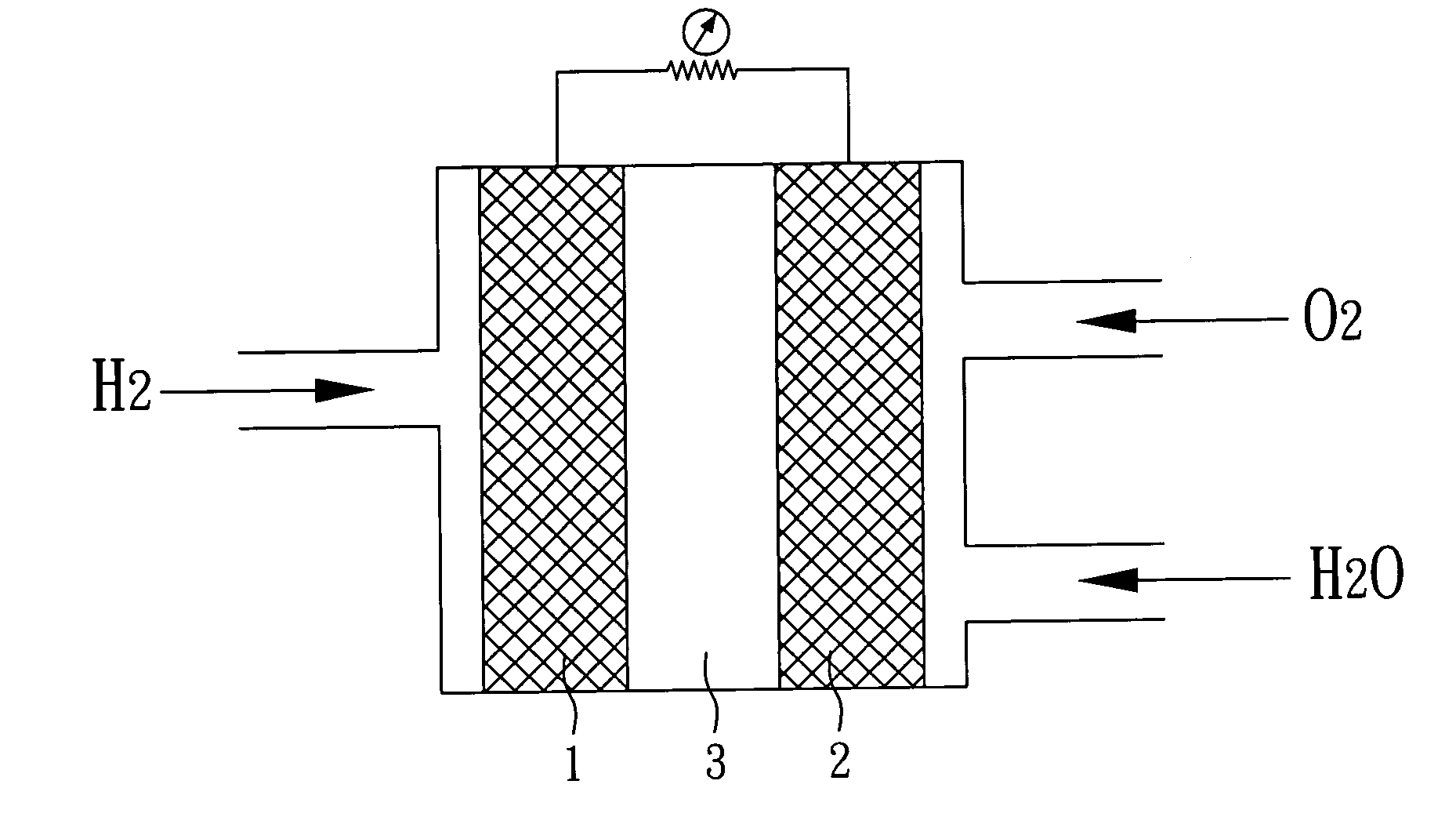

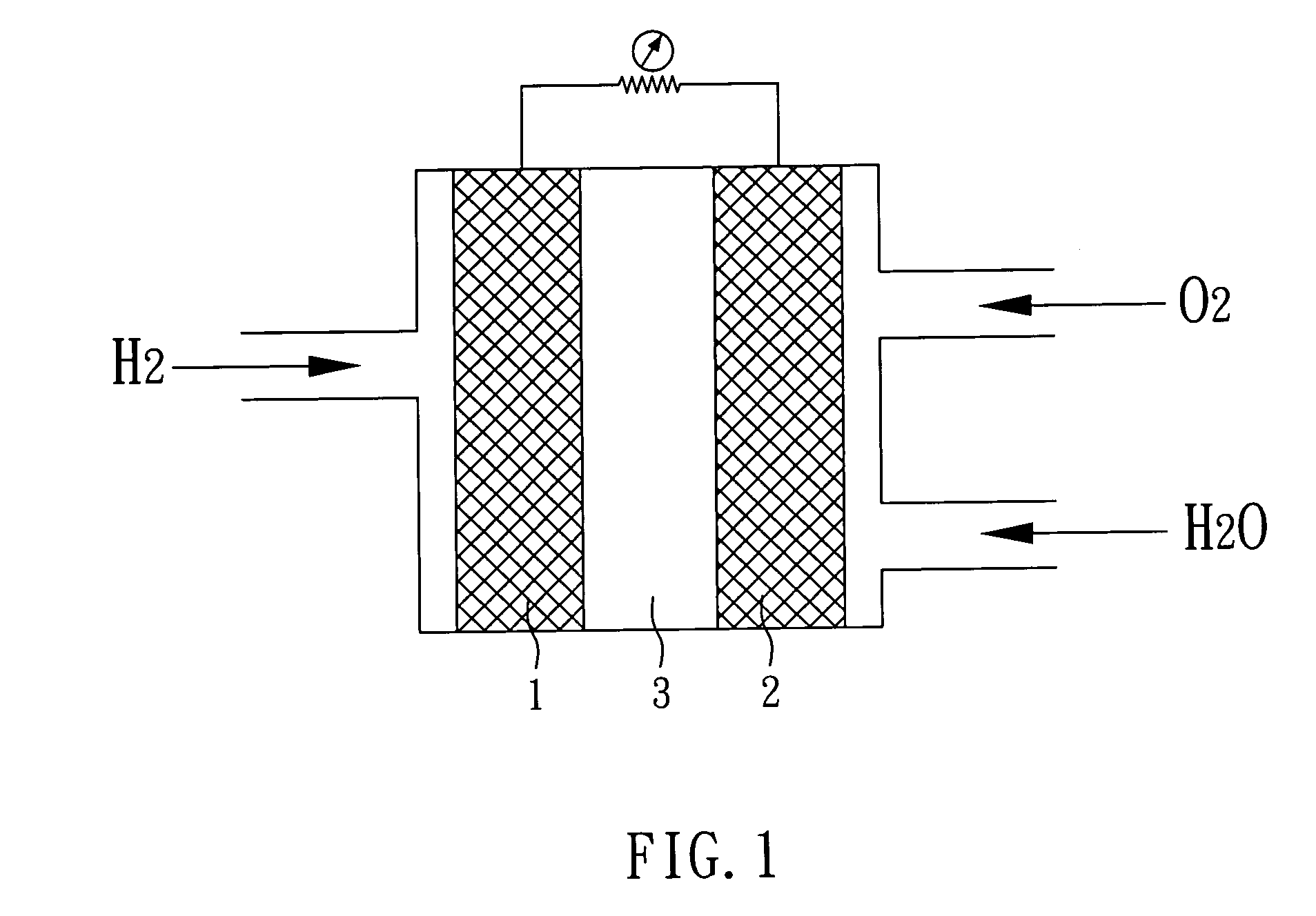

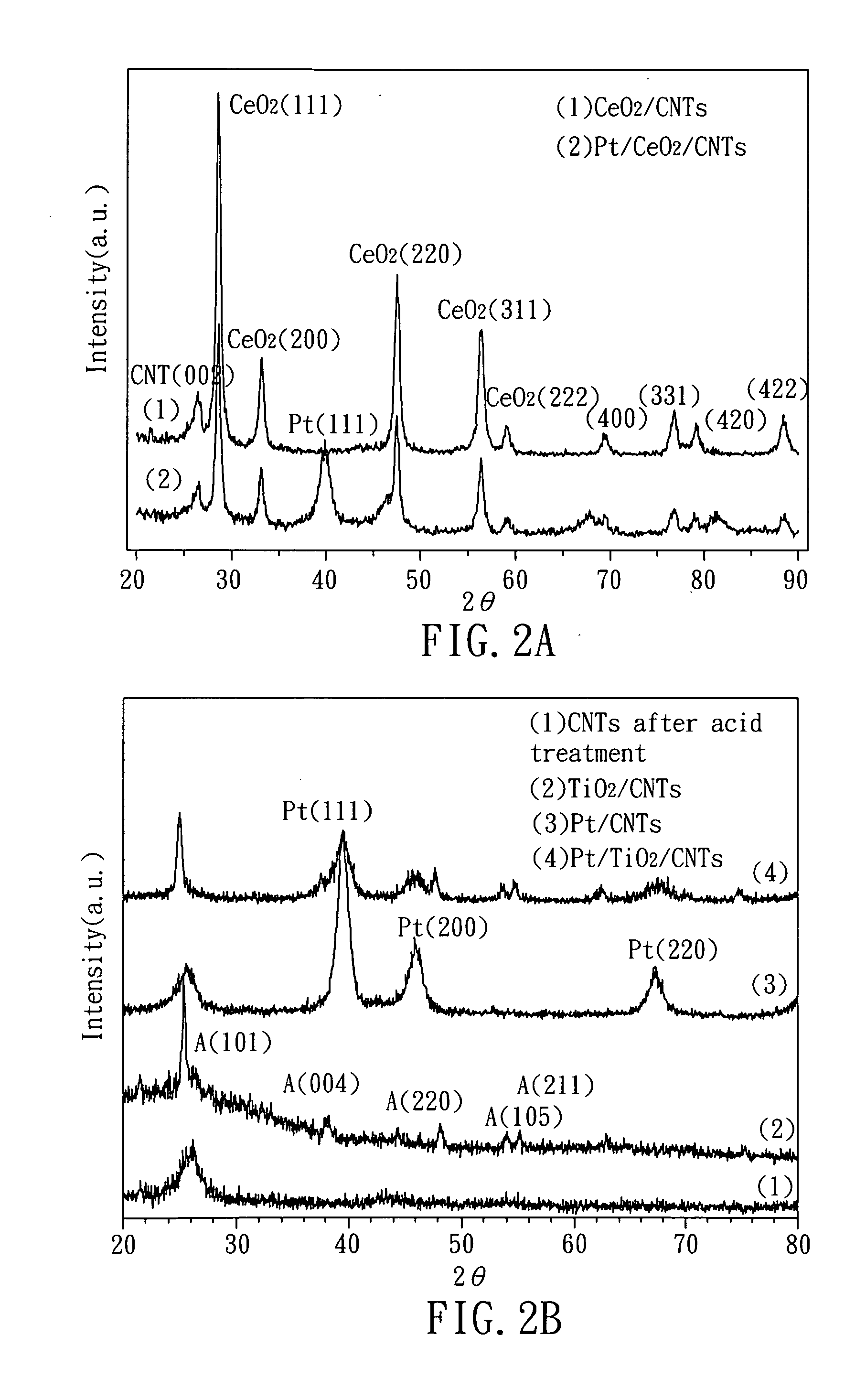

Hybrid catalyst, method of fabricating the same, and fuel cell comprising the same

InactiveUS20100285397A1Improve uniformityAvoid it happening againMaterial nanotechnologyActive material electrodesFuel cellsHigh carbon

A hybrid catalyst is disclosed, which has a structure of Pt / oxygen-donor / carbon-nanotube. The hybrid catalyst has a superior electrochemical characteristic and high carbon monoxide conversion efficiency even in a low reacting temperature, and thus is useful at detoxification of carbon monoxide. Besides, the oxygen-donor utilized in the present invention is cheap and is commercially reachable, therefore the hybrid catalyst of the present invention is advantageous in commercial usage. Also, a method of fabricating the above hybrid catalyst and a fuel cell comprising the above hybrid catalyst are disclosed.

Owner:TATUNG UNIVERSITY +1

Crude oil recovery method

The invention discloses a crude oil recovery method. The method comprises placing a mixture in a condition which enables the heavy components of heavy oil to be under catalytic cracking for reaction, wherein reaction products serve as blending diluting oil to be injected into an oil well to recover the crude oil in the oil well, the mixture is composed of the heavy oil, catalysts and water which have a weight ratio of 1: (0.00004-0.01): (0.02-1.5). According to the crude oil recovery method, the viscosity of the heavy oil which is provided with a dynamic viscosity not less than 1000mPa*s after degassing and dewatering at a temperature of 50 DEG C can be reduced without additional hydrogen donors or oxygen donors, the catalytic viscosity reduction effects are good, and the obtained blending diluting oil can be injected into the crude oil to a certain scale to achieve diluted oil recovery. Meanwhile, the method does not require any other additives, achieves the aim of preparing the blending diluting oil in a short time and at a low temperature and a low pressure, solves the problem of thin oil scarcity of certain oil fields and is applicable to the practical application of oil fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com