Method for preparing aluminium titanate film by non-hydrolytic sol-gel process

A technology of aluminum titanate and sol, which is applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of demand and high equipment cost, and achieve the effects of simple process, low synthesis temperature, and shortened preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

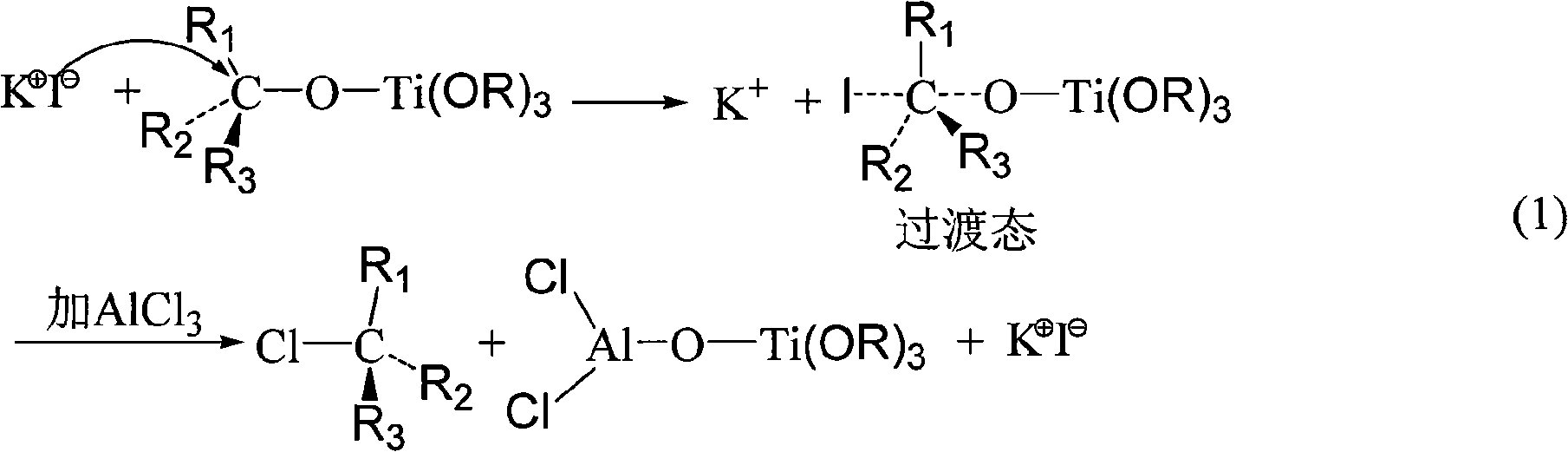

Method used

Image

Examples

Embodiment 1

[0026] Prepare aluminum titanate sol according to the molar ratio of aluminum to titanium of 2:1, weigh 2.667g of anhydrous aluminum trichloride (analytical pure) and dissolve in 3.4ml tetrabutyl titanate (analytical pure), then add 0.037g KI (analytical pure) ) heated and stirred to AlCl 3 After completely dissolving with KI, reflux at 110°C for 0.5h to obtain a black-brown precursor mixture; add 0.050g of tetrabutylammonium bromide (analytical pure) to 50.0ml of AGSE (industrial pure), heat and stir until completely dissolved to obtain tetrabutylammonium bromide AGSE solution of butyl ammonium bromide, sealed for use; measure 50.0ml of AGSE and add it to the refluxed precursor mixture, stir evenly, and then slowly add the prepared tetrabutylammonium bromide-AGSE solution to it to obtain bright yellow For transparent aluminum titanate sol, add 5.0ml diethyl phthalate as a drying control additive, stir at room temperature for 1 hour, and age at 110°C for 24 hours to obtain lig...

Embodiment 2

[0028] Prepare aluminum titanate sol according to the molar ratio of aluminum to titanium of 2:1, weigh 4.005g of anhydrous aluminum trichloride (analytical pure) and dissolve in 5.1ml tetrabutyl titanate (analytical pure), then add 0.067g NaI (analytical pure) ) heated and stirred to AlCl3 After completely dissolving with NaI, reflux at 110°C for 24 hours to obtain a dark brown precursor mixed solution; add 0.300g tetrabutylammonium bromide (analytical pure) to 50.0ml AGSE (industrial pure), heat and stir until completely dissolved to obtain tetrabutylammonium bromide The AGSE solution of butylammonium bromide, sealed for use; then measure 50.0ml of AGSE and add it to the precursor mixture that has been refluxed, stir evenly, and then slowly add the prepared AGSE solution of tetrabutylammonium bromide to obtain orange Red transparent aluminum titanate sol, then add 5.0ml diethyl phthalate as a drying control additive, stir at room temperature for 1h, and age at 110°C for 12h t...

Embodiment 3

[0030] Prepare aluminum titanate sol according to the molar ratio of aluminum to titanium of 2:1, weigh 5.336g of anhydrous aluminum trichloride (analytical pure) and dissolve in 6.8ml tetrabutyl titanate (analytical pure), then add 0.084gMgI 2 (analytical pure) heated and stirred to AlCl 3 and MgI 2 After completely dissolving, reflux at 110°C for 12 hours to obtain a dark brown precursor mixture; add 0.300g tetrabutylammonium bromide (analytical pure) to 50.0ml AGSE (industrial pure), heat and stir until completely dissolved to obtain tetrabutylammonium bromide The AGSE solution of ammonium bromide, sealed for use, then measure 50.0ml of AGSE and add it to the refluxed precursor mixture, stir evenly, and then slowly add the prepared AGSE solution of tetrabutylammonium bromide to it to obtain orange-red transparent Aluminum titanate sol, then add 5.0ml dimethyl phthalate as a drying control additive, stir at room temperature for 1h, and age at 110°C for 12h to obtain dark re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com